Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Top Circuit Board Assembly Services in China

Circuit board assembly services play a crucial role in the electronics sector, serving as the backbone for the production of a wide variety of electrical devices that we rely on every day. In order to construct functional electronic circuits, these services include a crucial step in which electrical components are carefully positioned into printed circuit boards (PCBs).

In the circuit board assembly process, a number of electrical components, including integrated circuits, resistors, capacitors, and different kinds of connections, are carefully soldered and assembled onto a bare PCB. This essential procedure transforms a simple, blank board into a complex electrical system capable of performing specific functions.

Overall, circuit board assembly services are indispensable in shaping the landscape of modern electronics, enabling innovation and technological advancement across numerous industries. From consumer gadgets to sophisticated industrial applications, the expertise involved in circuit board assembly is what makes our electronic world function seamlessly. Then, let me introduce the PCB assembly process to you!

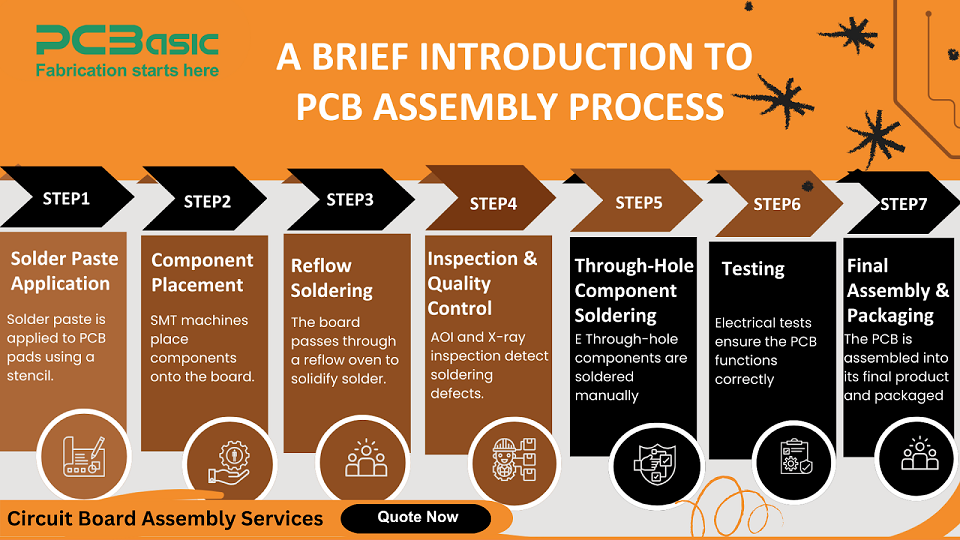

Printed Circuit Board (PCB) Assembly is defined as the mounting of electronic components on a Printed Circuit Board to achieve a functional circuit. There are several steps in this process to make sure the reliability and functionality of electronic devices are met. Let's examine the important processes:

1. Application of the Solder Paste

A stencil is used to apply solder paste to the predefined places on the PCB, where components will be put into position. This paste contains solder particles with flux that are meant to bond effectively.

2. Placement of Components of the PCB

Boards of resistors, capacitors, and ICs are attached to the solder-pasted boards by Surface Mount Technology (SMT) machines. This operation is automated for maximum efficiency.

3. Soldering Reflow

In this step, the PCB is put in a reflow oven. Because the soldering paste's melting temperature is lower than the soldering temperature, the components are melted into place at the PCB. The solder profile of the oven is designed in a way that the components are not damaged while reaching the required temperature.

4. Quality Control / Inspection

Post soldering, the board, to check for any alignment, soldering mistakes, or missing parts, Automatic Optical Inspection (AOI), and X-ray inspection for more complicated boards are used.

5. Soldering of Through Hole Components (When required)

Through hole components can be soldered using hand soldering, and wave soldering, wherein solder in a molten state is poured on the leads of the components.

6. Testing

During the testing stage, the employee identifies and corrects possible electrical issues with ICT and Functional Testing to ensure the board works properly before the last assembly stage.

7. Final Assembly & Packaging

After testing, the device is put within its final housing and packed for shipment or put into a greater device system.

PCB assembly is a crucial step in electronics manufacturing, ensuring that components are correctly placed, soldered, and tested for quality and performance.

Cost-Effective Production

Outsourcing PCB assembly to China provides global businesses with cost advantages. Sourcing from China enables companies to reduce production costs due to the high-quality services offered at low prices by Chinese manufacturers.

Labor Costs

Part of the savings can be attributed to the lower labor costs in China compared to Western countries. The skilled labor available to China's PCB assembly industry is much cheaper than skilled labor in developed countries. For businesses, this means huge savings, especially for China's Assembly of PCBs.

Economies of Scale

Most Chinese providers of PCB assembly services work on a bigger scale which gives them a competitive edge over other manufacturers. Bulk purchasing of components and materials reduces the overall cost of production. Clients receive these benefits in the form of low prices and high-quality services.

Advanced Technology and Equipment

China constantly invests in technology and high-end PCB assembly equipment. Some Chinese producers of PCBs and other electronic components claim that their factories are equipped with very advanced and even better than those in the West.

Latest SMT Technology

Nowadays in China, SMT is adopted in almost all PCB assembly plants. With the newest SMT machinery, it is possible to place even smaller parts with higher densities for more sophisticated and compact PCBs.

High-Volume Production

Given the size of the Chinese manufacturers and their developed processes, supplying large orders is no problem at all as they are experts in greatly outsourcing mass production.

Quality and Certifications

Some may argue that Chinese PCB assembly service providers lack quality, but this is untrue. A lot of service providers do offer quality services along with several industry certifications.

These certifications demonstrate a commitment to quality and compliance with international standards, assuring businesses outsourcing their PCB assembly to China.

China features prominently in the international value chain and is recognized for its Chinese PCBA contract manufacturing plants. Due to the fierce competition in technology, PCBA contract manufacturers in China possess immeasurable experience in production, and with robust production capabilities, they are now able to provide reasonable rates for high-quality PCBA contract manufacturing services to countries all over the world.

These services are highly valuable across several industries such as consumer electronics, automotive, telecommunications, and avionics for the complex and precise needs of the global electronic manufacturing service market.

This article aims to showcase some of the top-tier centers in China that specialize in PCBA contract manufacturing and offer a full range of services from Electronics Manufacturing Services (EMS) to PCB assembly and many other types of Contract Manufacturing Services (CMS). Let us learn about their unique features, which place them ahead of the competition in China and make them a center of excellence for PCBA contract manufacturing.

|

Company Name |

Company Address |

Establishment Year |

Main Services Provided |

|

Dongshan Precision |

Suzhou, China |

1980 |

HDI PCBs, Flexible PCBs, Rigid-Flex PCBs, PCB Assembly |

|

Shennan Circuits |

Suzhou, China |

1984 |

High-layer PCBs, HDI Boards, Rigid & Flexible PCBs, PCB Assembly |

|

Unimicron Electronics |

Multiple locations in China |

1990 |

HDI, Any-layer, IC Substrates, PCB Assembly |

|

Kinwong Electronics |

Guangzhou, China |

1993 |

Single-layer to Multi-layer PCBs, HDI, Flex, Rigid-Flex Automotive PCBs |

|

Shenzhen Depuqe Technology |

Shenzhen, China |

2005 |

High-frequency & High-speed PCBs, HDI, Multilayer PCBs, PCB Assembly |

|

PCBasic JS Technology |

Shenzhen, China |

2011 |

High-frequency, High-speed PCBs, HDI, Multilayer PCBs, PCB Assembly |

Dongshan Precision Manufacturing as a leading electronics manufacturing service provider in China, focuses on providing precision sheet metal, flexible circuit (FPC), and rigid printed circuit board (PCB), and also has PCBA contract manufacturing services. Dongshan Precision's main business includes the production and assembly of electronic components, covering many fields such as consumer electronics, automotive electronics, intelligent equipment, communication equipment, and medical electronics.

Dongshan Precision also expanded its PCBA foundry business through the acquisition of Multek, a well-known American company, further enhancing its competitiveness in the global market. DSBJ's PCBA plant is equipped with the latest automated SMT production lines and test facilities to provide high-quality, precise assembly for a wide range of complex applications. As a wholesale PCBA contract manufacturing supplier, DSBJ maintains a high level of production quality while offering competitive prices.

Their comprehensive EMS solutions make them one of the leading PCBA contract manufacturing suppliers in China, capable of maintaining efficiency and precision in both small and large-scale production, and one of the ideal choices for reliable and cost-effective PCBA manufacturing solutions.

Focused on Shanghai, the company is a contract manufacturer for PCBA with clients from all over the globe. Established in 1984, Shennan Circuits has managed to acquire a reputation for being one of the leading manufacturers in China. SCC offers its clients complete solutions for PCB including design, production, and assembly services which guarantees high quality for all business processes. The company stands for innovation by providing strong technical and business value to its clients since its foundation. Their advanced dealing and strong nurturing abilities helped the organization grow a considerable amount of strengths in the telecom, automotive, medical, and consumer electronics industries. Additionally, they provided them with all of the necessary equipment to function including contract assembly of the China.

Some of the company's main products include flexible PCBs (FPC), single-sided and double-sided rigid PCBs, multi-layer PCBs, and high-density interconnect boards (HDI).

The business's core strengths were maintained through the years with the accent being placed on custom design and manufacturing assembly immensely influencing positive brand reputation worldwide. The company encourages customization based on specific customer feedback which allows it to solve various technical puzzles providing Impressive ROI. Ultimately, the Shennan Circuits brand has earned its reputation through innovation and adaptation to customer needs. Their trust can mainly be attributed to the company's strength in high technology.

Unimicron Electronics, together with its competitors, leads the contract PCBA manufacturing in China. Founded in 1990, Unimicron focuses on PCB design, PCB Assembly, and SMT services execution.

Unimicron's PCBA plants are well equipped with a variety of technology and automation tools, enabling high-performance PCBA solutions for automotive, telecommunications, and computer industries. Unimicron is recognized for high-quality contract PCBA manufacturing services that satisfy the specific demands of all its customers.

An established PCBA provider, Unimicron is a complete EMS service provider with design, test, and assembly capabilities. Unimicron is particularly competent in the manufacturing of HDI PCBS which makes Unimicron the preferred choice for companies needing sophisticated and superior quality PCBA contract manufacturing services.

Kinwong Electronics, just like its competitors, operates in the field of PCBA contract manufacturing in China. It is known for its ability to manufacture medium-sized batches competitively. Kinwong Electronics operates in high-precision PCB assembly and advanced SMT solutions and serves multiple industries including telecommunications, consumer electronics, and automotive.

As one of the leading PCBA contract manufacturers, Kinwong provides a comprehensive suite of services which include PCB Benchtop Prototyping, PCB Assembly, and Testing. Kinwong's plants for PCBA Virgin Islands are equipped with sophisticated machines that permit the undertaking of both low and high-volume production runs, thus enabling efficient and flexible manufacturing processes across the system.

PCBasic specializes in contract manufacturing PCBs for Patient-Centered Medical Home (PCMH) and is focused on low to medium-mix volume production. However, like most industry-leading companies, PCBasic can also produce high volumes. Unlike industry leaders, PCBasic focuses on low and medium-mix volume production along with providing tailored PCBA contract manufacturing services. PCBasic bears the burden of offering cost-effective solutions for every single one of their customers whether it be for contract PCB assembly or complete PCBA.

As a top-tier assurance provider, the company claims to be applicable in sectors such as medicine, consumer electronics, military aerospace, and several others. PCBasic has invested in the best available technology to fully automate its PCBA facility and is capable of advanced flying probe testing, welding, selective wave soldering, and x-rays.

In addition to these technologies, PCBasic is committed to delivering professional EMS solutions for speed and volume of prototyping, ensuring every customer receives specialized support.

Shenzhen Depue Technology Established in 2005, Shenzhen Depue Technology is one of the leading PCB assembly manufacturers in China. It specializes in high-speed, high-frequency PCBs with established capabilities in HDI and multilayer production.

Their primary business sectors include 5G, IoT, and automotive. They also maintain quality through UL, ISO 9001, and ISO 14001 certifications. Shenzhen Depue's focus on innovation is remarkable. The company invests in state-of-the-art equipment and technology to grow its production capabilities and remain competitive in the industry.

It is evident from the conclusion of our review of China's circuit board assembly services that this sector is vital to the global electronics manufacturing industry. Now, we'll review the main ideas covered and consider how PCB assembly will develop in China going forward.

In general, the circuit board assembly services market in China offers a promising opportunity for businesses looking for high-quality and cost-effective PCB assembly solutions. China is still a great place to outsource PCB assembly because of its experience, cutting-edge technologies, and extensive services.

As we wrap up our detailed overview of China's circuit board assembly services, it is evident that this sector plays a crucial role in the global electronics manufacturing landscape. The increasing demand for electronic devices worldwide has amplified the importance of efficient and effective PCB assembly. In this context, it is essential to summarize the key points we have discussed and to provide insights into the future prospects of PCB assembly in China.

Time is money in your projects – and PCBasic gets it. PCBasic is the pcb assembly company that delivers fast, flawless results every time. Our comprehensive PCB Assembly Services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB Assembly Manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB Prototype Factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.