Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Understanding SMD Assembly| SMD VS SMT

In the world of electronics manufacturing, SMD assembly and Surface Mount Technology (SMT) are central to creating compact, efficient, and reliable devices. From smartphones to medical equipment, these technologies are the foundation of printed circuit board assembly. This comprehensive guide explores what is SMT, what is SMD, and how these processes shape modern electronics manufacturing, focusing on their benefits, applications, and nuances.

Surface Mount Technology (SMT) is a method of assembling electronic circuits by mounting components directly onto the surface of a printed circuit board (PCB). This technique differs significantly from through-hole technology, where components are inserted into drilled holes on the PCB. By eliminating the need for holes, SMT allows for smaller and more efficient designs.

The term SMT encompasses the entire process of creating a circuit board using surface mount components. This includes placing SMD components on the board, soldering them, and performing quality checks. SMT’s ability to accommodate high-density circuit layouts has made it the standard for modern PCB assembly.

The adoption of surface mount technology in PCB assembly has revolutionized the electronics industry. Its numerous benefits include:

1. Compact Design: SMD assembly enables the creation of smaller and lighter devices by utilizing compact surface mount components.

2. Increased Reliability: Direct soldering of SMD components reduces mechanical stress, leading to enhanced durability.

3. Cost Efficiency: Automated processes in an SMT line reduce labor costs and minimize errors.

4. Improved Performance: High-density layouts achievable with SMT enhance circuit performance.

5. Faster Prototyping: Prototype PCB assembly is quicker and more efficient, facilitating rapid product development.

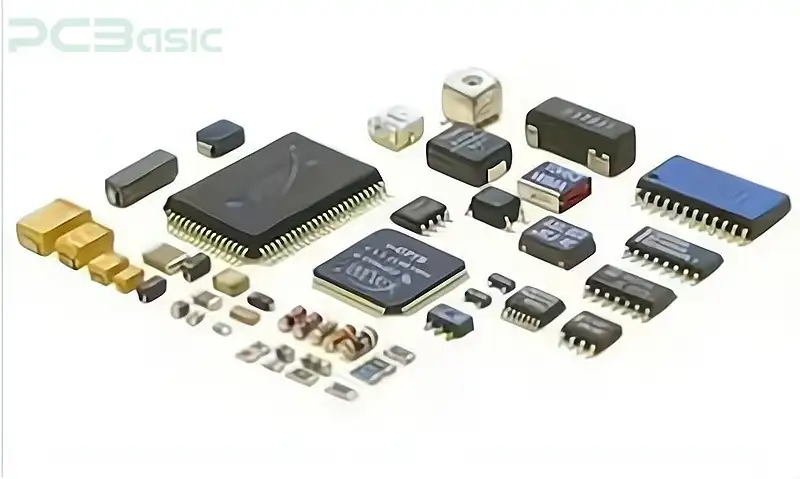

While SMT refers to the technology, SMD stands for Surface Mount Device—the actual electronic components used in SMT processes. These components are designed to be mounted on the PCB’s surface rather than inserted into holes. Common examples of SMD components include resistors, capacitors, diodes, and integrated circuits.

SMD assembly is a highly automated process that forms the backbone of circuit board assembly. Precision and efficiency are key, as modern devices require compact, multilayered PCBs. The main steps in SMD assembly include:

1. Solder Paste Application

The process begins by applying solder paste to the PCB using a stencil. This paste serves as an adhesive to hold the surface mount components in place before soldering.

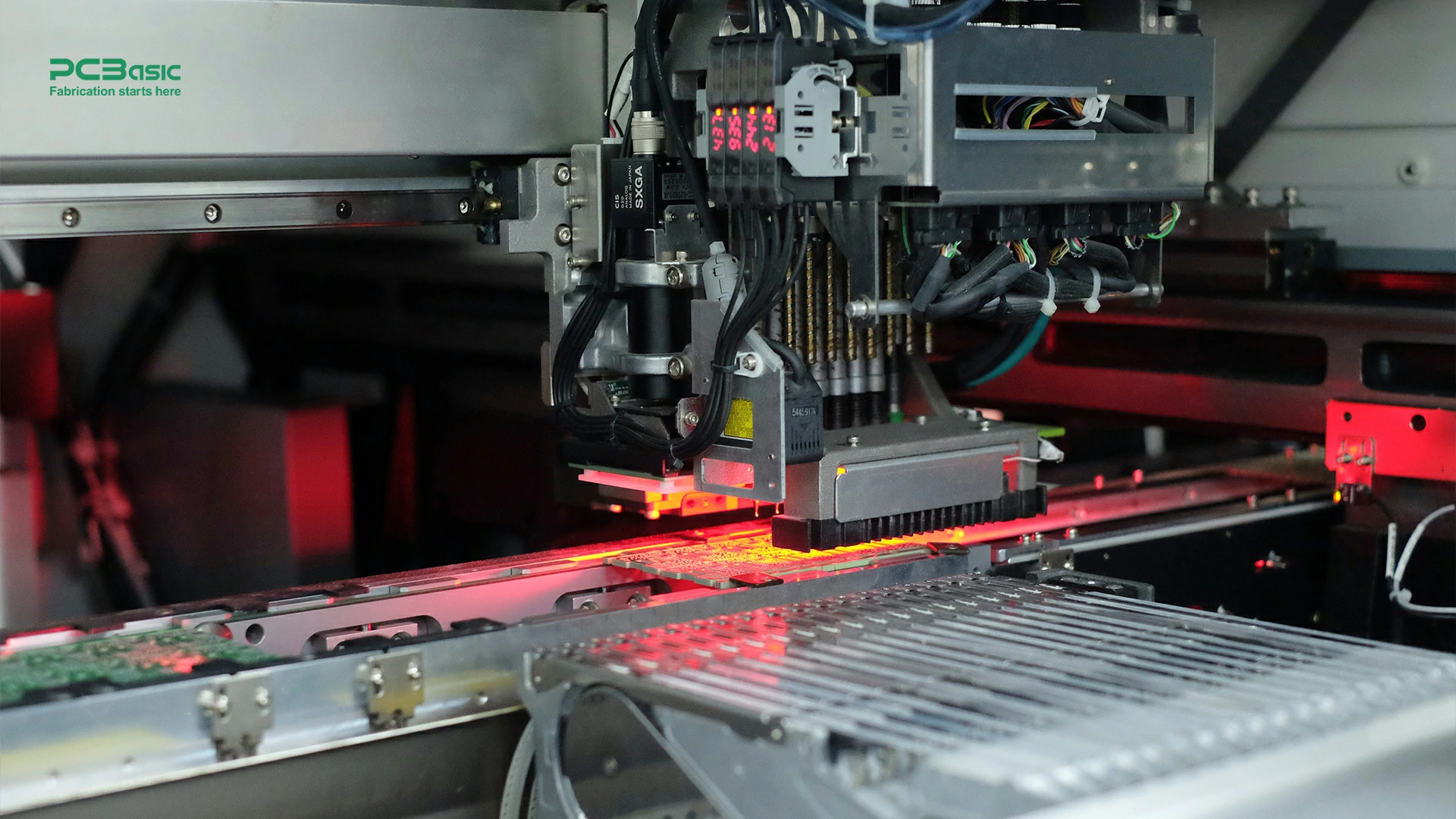

2. Pick-and-Place Assembly

Automated pick-and-place machines are a vital part of the SMT line. These machines accurately position SMD components onto the solder paste-covered pads of the PCB.

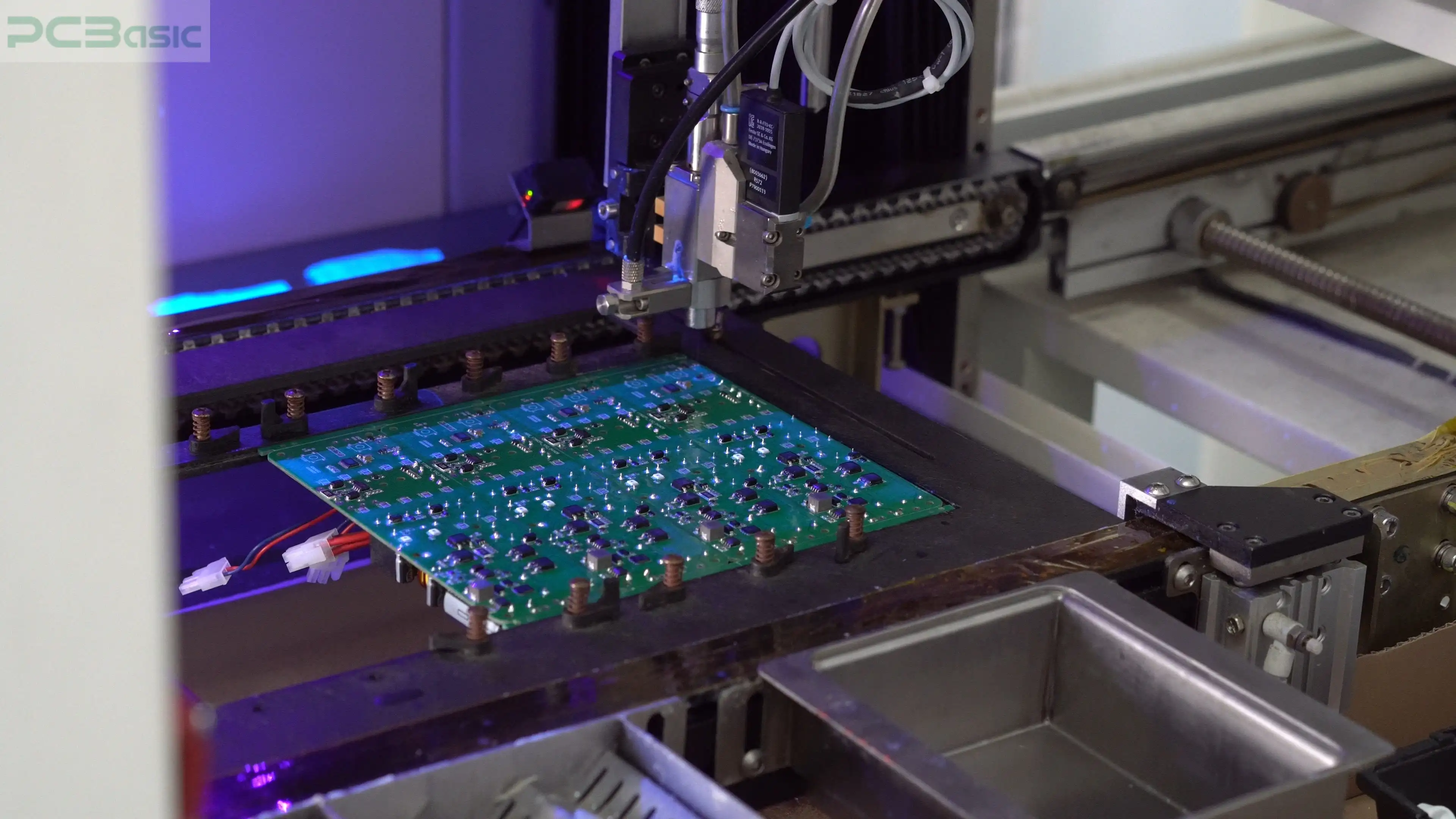

3. Reflow Soldering

In this step, the assembled PCB passes through a reflow oven. The heat melts the solder paste, securing the surface mounted components to the board.

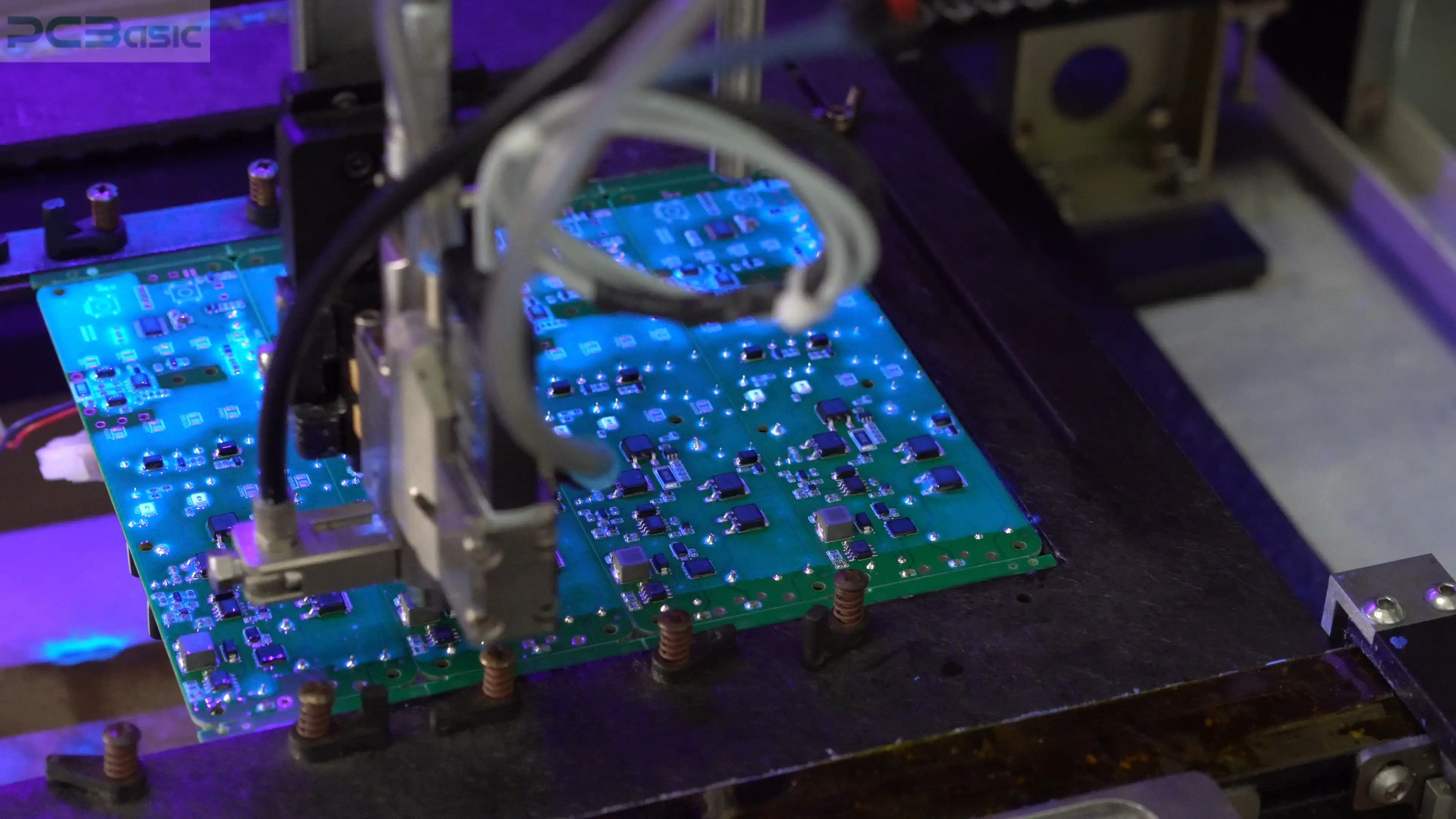

4. Inspection and Quality Control

After soldering, the PCB undergoes optical or X-ray inspection to ensure all SMD components are correctly positioned and soldered. This step is crucial for maintaining the quality of the printed circuit assembly.

Despite its advantages, SMD assembly comes with challenges:

However, advancements in machinery and techniques continue to address these challenges, making surface-mount technology more accessible.

The versatility of SMD assembly makes it indispensable across industries. Here are some of its major applications:

Understanding the distinction is critical when discussing SMD assembly, as it directly involves placing and soldering surface mount components.

Prototype PCB assembly is essential for developing new electronic products. During this phase, manufacturers test designs to ensure functionality before moving to large-scale production. Using SMD components and surface mount technology, designers can create prototypes that closely resemble the final product. This approach shortens development cycles and reduces costs, making it ideal for startups and innovators.

For businesses looking for a hassle-free solution, turnkey PCB assembly services offer end-to-end support. These services cover every aspect of the process, from PCB manufacturing and assembly to the final circuit board assembly. With turnkey solutions, businesses can focus on innovation while leaving production to experienced professionals.

Selecting the right PCB assembly manufacturer is crucial for successful projects. Key factors to consider include:

1. Expertise in SMD Assembly: Look for a manufacturer with proven experience in SMD assembly and SMT electronics.

2. Turnkey PCB Assembly Services: A comprehensive solution that includes PCB manufacturing and assembly simplifies the process.

3. Quality Assurance: Ensure the manufacturer has robust quality control measures in place for reliable printed circuit assembly.

4. Scalability: From prototype PCB assembly to mass production, the manufacturer should accommodate your requirements.

When it comes to reliable SMD assembly and PCB assembly services, PCBasic is a trusted partner for businesses worldwide. With over 15 years of experience and a reputation for innovation, PCBasic delivers high-quality solutions tailored to the diverse needs of its clients. Whether you need small-batch prototypes or large-scale production, PCBasic ensures precision, speed, and efficiency in every project.

PCBasic excels in SMD assembly thanks to its advanced facilities, experienced team, and customer-focused approach. Here’s what sets us apart:

1. One-Stop PCB Assembly Services

o Comprehensive solutions from online PCB design and manufacturing to full-scale PCB assembly.

o Expertise in both prototype PCB assembly and mass production.

2. Innovative Production Systems

o Self-developed CRM, MES, ERP, and IoT management systems for enhanced process automation.

o Advanced equipment, including an LCR incoming inspection system and SMT fault detection system, ensures top-tier quality.

3. Certified Quality Standards

o Certified by ISO9001, IATF16949, and ISO13485 for quality assurance.

o Winner of the national high-tech enterprise award, reflecting our commitment to excellence.

4. Diverse Industry Applications

o Core service areas include industrial control, smart home, medical devices, automotive electronics, and aviation.

o Proven expertise in PCB manufacturing and assembly for various high-demand industries.

1. Expert Team

o Over 200 employees, including 30+ experienced PCB designers, 20 quality management specialists, and a dedicated R&D team.

o 24-hour support to address customer queries and provide professional PCB assembly services.

2. Cutting-Edge Technology

o Use of intelligent material racks and ESD electrostatic protection systems for safe and efficient assembly.

o Focus on high-quality surface mount components and precise SMD electronics.

3. Scalability and Flexibility

o Capable of handling multi-variety small batches and large-scale production.

o Tailored solutions to meet the specific needs of clients across different sectors.

The future of SMD assembly and surface mount technology is exciting, with trends such as:

1. Miniaturization: As devices become smaller, the demand for compact SMD components will grow.

2. Automation: Enhanced automation in SMT lines will improve efficiency and reduce costs.

3. Sustainability: Eco-friendly materials and processes will become a priority in PCB manufacturing and assembly.

4. IoT and Wearables: The rise of IoT and wearable devices will drive innovations in SMT electronics.

SMD assembly and surface mount technology are indispensable in modern PCB assembly. By understanding what is SMT, what is SMD, and how these processes integrate into printed circuit board assembly, businesses and engineers can harness their full potential. Whether you're developing a prototype or scaling up production with a reliable PCB assembler, mastering these technologies is key to success in today’s competitive electronics market.

For those seeking PCB assembly services, working with an experienced PCB assembly manufacturer ensures high-quality results, whether you need turnkey PCB assembly or support for prototype PCB assembly. Embracing the capabilities of SMT electronics and SMD assembly is the path to creating innovative, reliable, and cutting-edge devices.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.