Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Prototype Circuit Board Assembly Services from PCBasic

PCBasic is dedicated to providing high-quality prototype circuit board assembly (PCBA) services for all industries. Its functionality is aimed at optimizing the cycles of product development for businesses, ensuring that every prototype is tested, improved, and ready for manufacturing.

PCBasic is your partner of choice in the domain of circuit board assembly, advanced manufacturing technologies, and surface mount assembly.

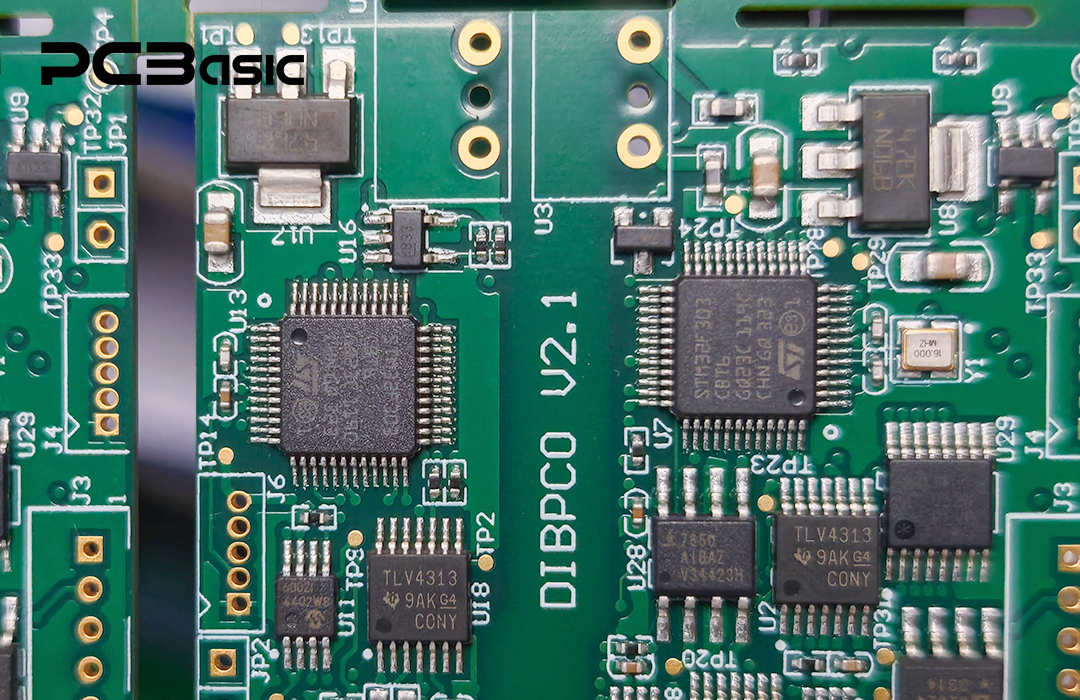

Prototype PCB assembly refers to a series of assembly, testing, and verification work for small batches of printed circuit boards (PCBs) before mass production. The core purpose of this process is to ensure that the circuit board is designed to function as intended and to demonstrate stability and reliability in practical applications.

During prototype circuit board assembly, the design team will typically use a small number of boards for functional verification and testing. These early assembly tests allow you to evaluate the board design for design errors, functionality, or manufacturing process problems. For instance, improper wiring, component layout problems, unstable electrical connections, or inadequate thermal management can be made in time to detect and solve them before mass production, avoiding costly repairs and production when mass production is delayed.

Besides that, prototype PCB assembly can also allow the development team to confirm that the selected components are suitable for this project that the dimensions and layout of the circuit board can be complied with the product requirements and the assembly process can be carried out smoothly. The design team will re-evaluate the original PCB design(s) and refine it based on real-world results from these tests to ensure that the production version is capable of meeting the performance requirements.

PCBasic focuses on one-stop PCB assembly, covering the whole process from PCB design and assembly to final testing and delivery. Its experienced team works closely with customers to provide high-quality PCB assembly services.

• Early Detection of Issues: By performing prototype PCB assembly, designers can identify potential design defects or manufacturing issues at the early stage of product development. If a problem is found in the prototype phase, engineers can make changes and adjustments in time, rather than waiting until mass production to find out, avoiding a lot of rework and repair costs.

• Cost Efficiency: Prototype circuit board assembly provides you with a valuable opportunity before officially entering mass production. By testing prototypes, designers can verify the feasibility of circuit design, component selection, and manufacturing process, thereby reducing the high cost of design errors or improper choices later.

• Faster Time-to-Market: The prototype circuit board assembly can significantly accelerate the development and verification process of products. Turnkey PCB assembly and conducting tests help enterprises identify and solve design or functional problems in the shortest time, thereby rapidly advancing the subsequent development work of the products. With an efficient prototype production process, designers can avoid wasting time on incorrect design directions and instead can rapidly iterate and optimize the design to enter the production stage quickly. Especially in a highly competitive market, shortening the time to market means that enterprises can occupy the market before other competitors and seize more business opportunities.

• Customizability: Prototype circuit board assembly provides great flexibility in design. During the design process, products are often iterated and optimized many times. Therefore, prototype circuit board assembly is the ideal solution for this flexible customization. Through prototype testing, designers can easily change circuit layout, component selection, or modify other design details for different versions of the test validation. Compared with traditional production models, prototype assembly allows product design to become more flexible and able to respond quickly to changes in the market and technology.

• Improved Quality: Prototype board assembly is not only functional testing but also directly linked with the quality of the final product. This way, solutions are applied at an early stage so that by the time the board goes into mass production, the quality is at a very high standard. From repeated testing and optimization, prototypes can help designers pinpoint detailed issues in the design, such as incorrect component selection, signal forwarding, and noise interference, and ultimately enhance the overall reliability and performance of the product. In other words, it can better reduce the risk of failure after mass production by solving quality problems in the prototype stage and realizing market performance more steadily.

• Custom Solutions: Working with an experienced PCB assembly company, such as PCBasic, allows businesses to obtain tailor-made solutions. Whether you need to deal with small-batch prototype assembly or more complex design needs, they can provide flexible and efficient services. Whether to validate a new design or to solve technical problems in production, prototype PCB assembly manufacturers can provide you with the best solutions.

PCBasic is a leading one-stop PCB assembly manufacturer, providing full process services for PCB assembly from prototype PCB assembly to high-volume production. It combines advanced technology, quality assurance, and efficient management systems within its 15 years of board assembly services in the SMT industry.

• Extensive Experience and Professional Team

PCBasic boasts a team with over 10 years of experience in PCB design and project management, including more than 30 PCB design engineers and 20 quality management experts. With over 200 employees in total, the company provides 24/7 customer support to meet all prototype PCB assembly needs.

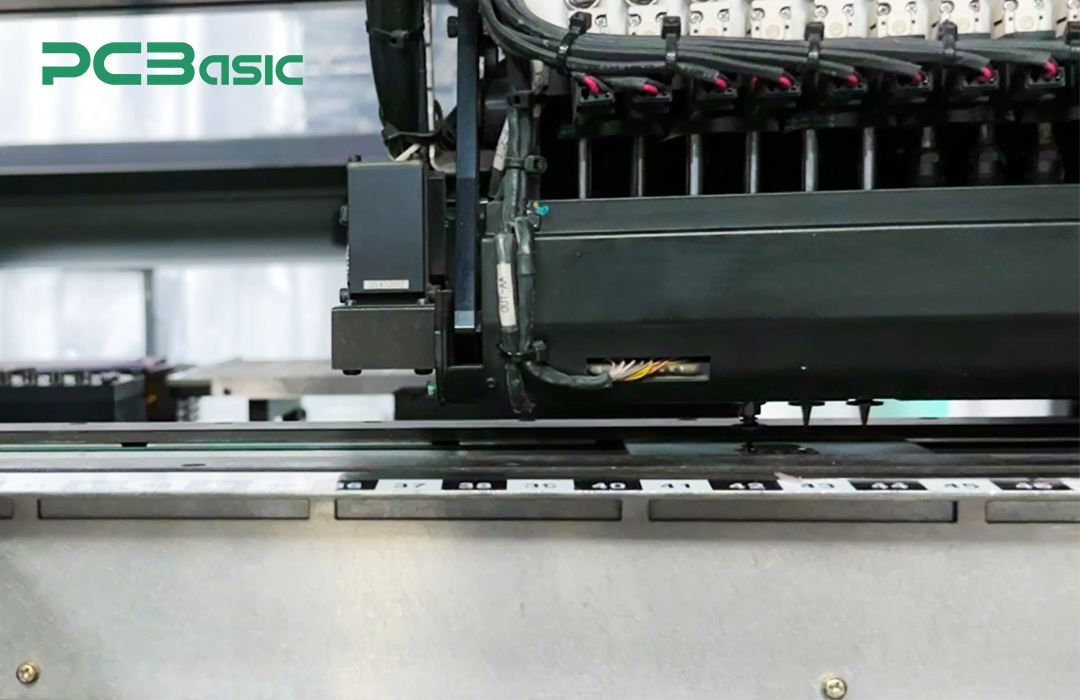

• Advanced Facilities and In-House Capabilities

With more than 10 years of experience in PCB design and project management, PCBasic consists of more than 30 PCB design engineers and 20 quality management experts. They comprise over 200 employees in total and can provide 24/7 customer support tailoring to all prototype PCB assembly needs.

• Smart Supply Chain and Automated Systems

The company has a factory in Shenzhen specifically for small-batch manufacturing, and a larger manufacturing factory in Huizhou. The group also cast stencil factories and has CNC precision parts processing capabilities which are all part of its quick delivery of stencils within one-hour.

• Certified Quality Standards

PCBasic has achieved ISO9001, IATF16949, and ISO13485 international quality certifications. As an IPC member with over 20 patented quality inspection technologies, the company demonstrates its commitment to delivering superior quality.

• Cutting-Edge Technology Support

The company has independently developed CRM, MES, ERP, and IoT management systems to optimize operations, accelerate delivery times, and enhance efficiency. Advanced SMT fault detection systems and electrostatic protection systems further ensure product reliability.

• Diverse Application Fields

PCBasic serves a wide range of industries, including industrial control, smart home devices, medical electronics, automotive electronics, aviation, and more, providing comprehensive solutions tailored to customer needs.

PCBasic stands out as a premier PCB assembly company offering exceptional prototype circuit board assembly services. With its extensive experience in PCB manufacturing and assembly, cutting-edge technology, certified quality standards, and comprehensive service offerings, PCBasic is the ideal partner for businesses seeking reliable printed circuit board assembly services. Whether it's SMT PCB assembly or turnkey solutions, PCBasic delivers unparalleled value to clients worldwide.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.