Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > A Leading Printed Circuit Board Assembly Manufacturer - PCBasic

In the cutthroat competition of the electronic device manufacturing world, it's pretty daunting to find a trusted printed circuit board services manufacturer. Fortunately, PCBasic has gained a reputation as a leading PCBA manufacturer.

With over 10 years of experience, we are proud to offer customized PCB & PCBA solutions. Additionally, our diverse solutions cater to the needs of various companies. This blog will help you understand the basic PCB assembly process and everything you need to know. Without further ado, let's get started.

Printed Circuit Board Assembly involves mounting electronic components onto a Printed Circuit Board (PCB). In essence, it is a finished board with all components soldered and installed on a PCB. The primary components that are mainly mounted on PCB include:

● Capacitors

● Resistors

● Diodes

● Transistors

● Integrated circuits

Printed Circuit Board Services manufacturers use the conductive pathways etched in the laminated copper sheets within the non-conductive substrate to create the PCB assembly.

While this process is complex, with precision and expertise, printed circuit board assembly manufacturer ensures the accuracy and reliability of the final product.

Let's categorize PCBA based on circuit type and components used.

Here are two types:

● Surface Mount Technology (SMT)

In this method, automated machines embed lighter and smaller components having small metal pads or lead directly on the PCB surface. This direct approach is perfect for miniature devices.

● Through-Hole Technology (THT)

This method is sometimes referred to as PTH (plated through-hole soldering). In this process, components with wire leads are inserted into the hole. Then, they are soldered opposite the side to ensure a secure mechanical and electrical connection.

● Single-sided Assembly: As the name suggests, in this type components are assembled on one side.

● Double-sided Assembly: Both sides of the PCB have components assembled on them. This method is more complex than single-sided assembly.

● Multilayer Assembly: This typically involves the assembly of components on multilayer PCBs and includes traces on inner layers.

Several critical steps are involved in the PCB assembly process. Here is a brief overview:

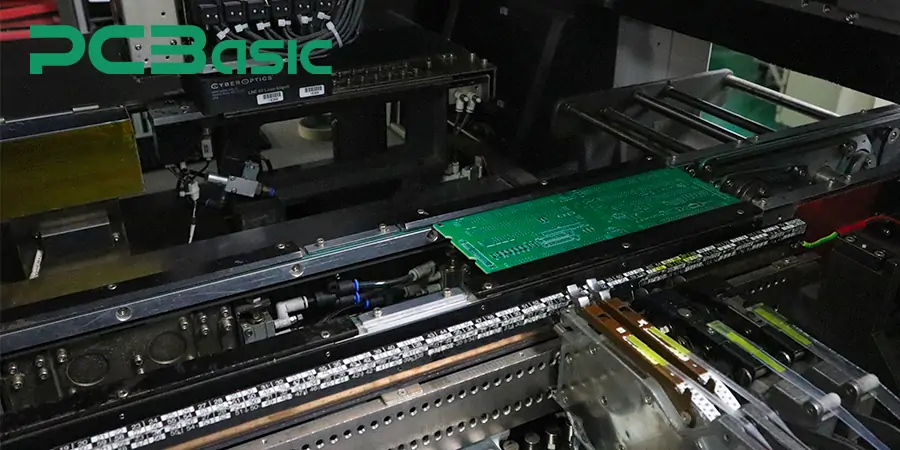

Step 1: Solder Paste Printing

The solder paste application marks the first step in the assembly procedure for PCBs. A stencil covers the board to permit paste application exclusively in component mounting areas. The paste consists of small solder particles together with flux material to facilitate proper solder bonding during heating.

The precise application of machines prevents both overapplication and underapplication of solder paste. An irregular distribution of solder paste throughout the board will create inferior component connections that may trigger short circuits.

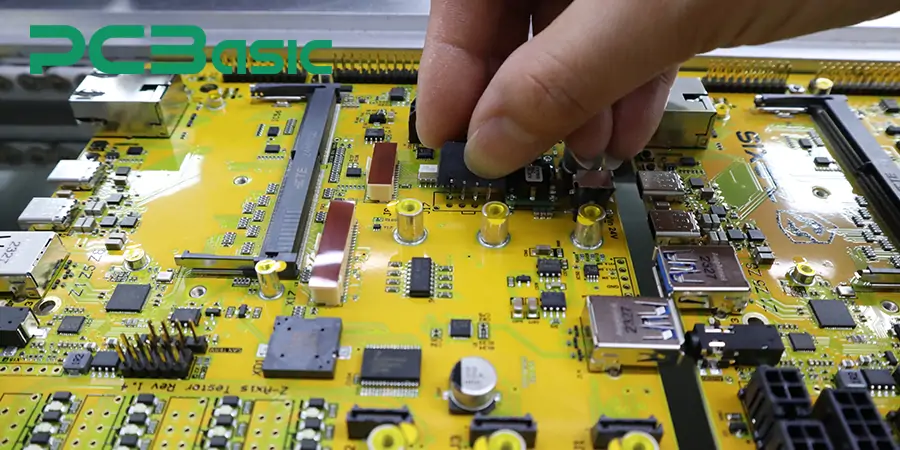

Step 2: Component Placement

After the solder paste is applied, automated pick-and-place machines position electronic components on the board. Vacuum nozzles on these machines extract components from reels or trays before they accurately place them on the PCB.

The precision of component placement stands crucial since minimal placement errors will impact system performance.

Step 4: Reflow Soldering

The PCB enters the reflow oven after all components are correctly placed. The oven heats the board in a controlled manner to achieve solder paste melting. The heating process unfolds through four sequential phases starting from preheating and continuing through soaking and reflow and ending in cooling.

Next, the solder bonds components to the board during the reflow stage when the temperature reaches 240°C. The connections become permanent after cooling down because solidification occurs.

Step 5: Inspection and Testing

The board undergoes inspection after the soldering process. AOI systems employ cameras and software to automatically detect both component misalignment and solder joint defects. X-ray inspection is used to examine complex boards which have hidden solder joints.

The technicians conduct manual error detection and correct any identified defects if found during the inspection process.

Step 6:Final Assembling and Quality Assurance

Functional testing is the last step of the PCB assembly process. Engineers confirm that boards function correctly by validating the performance of all circuits.

Our quality assurance process involves crucial steps to ensure perfection:

● We confirm the special requirements of customers along with the specs of the products (i.e., mobility, temperature resistance of structural special-shaped parts.)

● Secondly, we inquire whether the BOM and PCB net-making data are up-to-date. Also, if there are items to be confirmed.

● Thirdly, we evaluate if the shape (panel structure) process of PCB can be produced in bulk.

● This step also includes manufacturability evaluation of PCB special pad processes (OSP, chemical gold, tin spray, NSMD, SMD, etc.)

● Our competent team also verifies and evaluates the compatibility between special-shaped parts and PCB pads.

Technological breakthroughs have revolutionized the digital devices industry. Various businesses including automotive, telecommunication, and healthcare rely on advanced electronics to boost their performance.

Printed circuit board assembly services manufacturer helps these industries and others to get the most useful and high-quality circuit board that caters to their needs.

A well-assembled PCB helps in improving the efficiency, reliability, and functionality of electronic devices. Besides, it also serves in flawless performance and compact design of the product. Want to know what else it does? Here you go:

● Users prefer lightweight and smart gadgets. PCBA allows manufacturers to create compact and handy devices without compromising functionality.

● Signal loss in electrical devices can be a nuisance for users. PCB manufacturers use advanced techniques to enhance signal integrity and ensure high-quality performance, reducing the fear of signal loss.

● Maintaining quality standards and reducing the cost of production is only possible by utilizing automated PCB board assembly.

● Electronic devices need protection from environmental factors like vibration, moisture, dust, and heat. PCBA is the solution to protect electronic components from them, improving the product's longevity.

● Integrating a complex circuit becomes easy with PCB assembly.

A trusted PCB assembly manufacturer carefully connects with the client and turns his idea into a functional reality. Reaching out to a circuit board assembly service solves half the fuss of production.

PCBasic is one of the most trusted manufacturers of printed circuit board assembly. Our competent team knows how to use the most appropriate wand to make the magic happen efficiently. PCBasic's strong reputation as a leading PCB or printed circuit board assembly manufacturer makes it a preferred choice.

We offer a range of services, such as:

● Prototype development: To evaluate the designs before mass production.

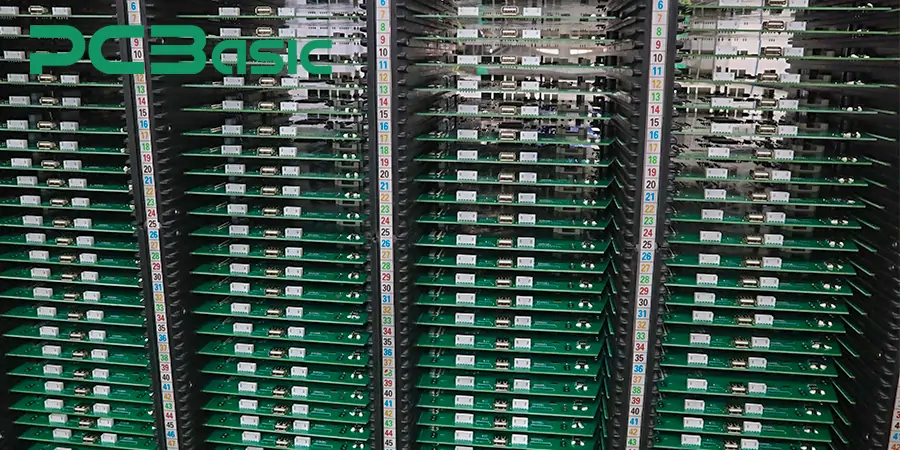

● Full-scale manufacturing: To satisfy increasing customer market needs.

● Component sourcing: Ensuring high-quality components from reliable suppliers.

● Product testing: The company executes thorough testing procedures that comply with industry requirements.

PCBasic offers Surface-mounted (SMT) PCB assembly, through-hole PCB assembly, Flex PCB assembly, PCBA components assembly, and single or double-sided PCB assembly.

You can rely on us for countless reasons, including:

● We thoroughly pay attention to every detail and ensure the highest quality standards for every assembly.

● Along with excelling in our craft, we pay close attention to our clients' needs and feasibility.

● Our quick turnaround lets customers with tight deadlines get the same-day consignment. In addition, there is no minimum order quantity. Fast PCB assembly takes 2-5 days, and High Volume requires only 10 days. The deliveries are scheduled and delivered on time.

Partner with PCBasic, and you will get:

● Quality focus as each assembly falls under strict compliance with ISO 9001, IATF 16949, and ISO 13485 standards.

● At PCBasic, we offer to buy PCBA and get free PCB so that it will be your best purchase.

● A customer-friendly refund policy in case of quality problems.

● 24/7 customer support for immediate response.

● Speedy delivery in case of a tight deadline.

● Exposure to advanced technology that will improve the efficiency of your product.

The world has switched to compact and easy-to-handle electronics, and PCB assembly is essential to minimize fuss and enhance product efficiency. PCBasic is the industry leader and one of the trusted PCB manufacturing partners you can rely on.

Whether you are looking for complex circuit integration, prefer fair pricing, want a fair DFM check, or have tight deadlines, PCBasic is the industry leader and top printed circuit board assembly manufacturer to serve you best. Contact our customer service team today and address your concerns.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.