Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What is PCBA in a Mobile Phone?

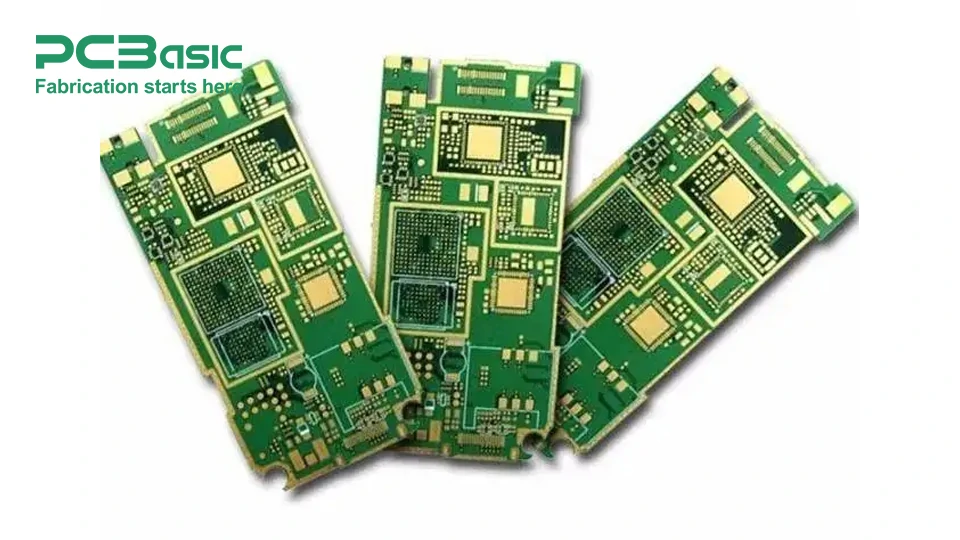

In all electronic devices, printed circuit boards (PCBs) are the core components of the normal operation of the products. Printed circuit board assembly (PCBA) is the core of electronic products, integrating various components such as processors, memory chips, sensors into a functional unit.

In this blog post, we will look in detail at the role of PCBA in mobile phones, including what PCBA is, the core components and PCBA’s importance to the operation of mobile phones. At the same time, if you have mobile phone PCBA needs, the end of this article will recommend a leading mobile phone PCBA manufacturer in China for you.

PCBA refers to the process of mounting various electronic components onto a printed circuit board. The PCB itself is a simple, blank board with no components, on which there are some conductive pathways, or called electrical circuits. These conductive pathways act as channels for current, helping it to flow between different components. But the PCB itself does not have any function, only through the different electronic components, such as resistors, capacitors, integrated circuits (ICs) and connectors, etc., soldered to the circuit board, it can become a truly functional circuit board, this process is called PCBA.

In a mobile phone, the PCBA is like a "central hub" where all the electronic hardware inside the phone is connected. The PCBA's task is to ensure the smooth exchange of data and power between these different components. It promises that the processor can communicate efficiently with the memory modules that the sensors can function properly, and power can be efficiently distributed to the various components. If the PCBA is not assembled properly, the various parts of the phone cannot work together, and the phone will not function properly.

In short, PCBA is the heart that makes the phone work properly, and it is responsible for connecting all the electronic components to ensure that the various functions of the device can perform smoothly.

PCBA manufacturing is a complex and precise process where each step is designed to ensure high precision and reliability. Each step is critical to the functionality and quality of the final product. Let's explore the entire PCBA process.

1. PCB Design

The first step in PCBA manufacturing is to design the PCB. At this stage, engineers use CAD to precisely design the PCB layout and determine the location of each electronic component. Designers need to consider the size, layout, number of layers and signal transmission requirements of the circuit board to ensure that the function of the circuit board in the phone is normal. This is the basis of PCBA - without a good design, effective PCB assembly cannot be carried out.

2. Component Placement

After the board design is complete, the next step is to place the electronic components onto the PCB. This step is usually done by automated equipment, such as a pick-and-place machine, which is able to precisely place very small components, such as capacitors, resistors, and ICs, onto the PCB. This step requires very high precision, because any deviation of components may cause the circuit board to work improperly. Correct component placement is one of the key steps to ensure a successful PCB assembly.

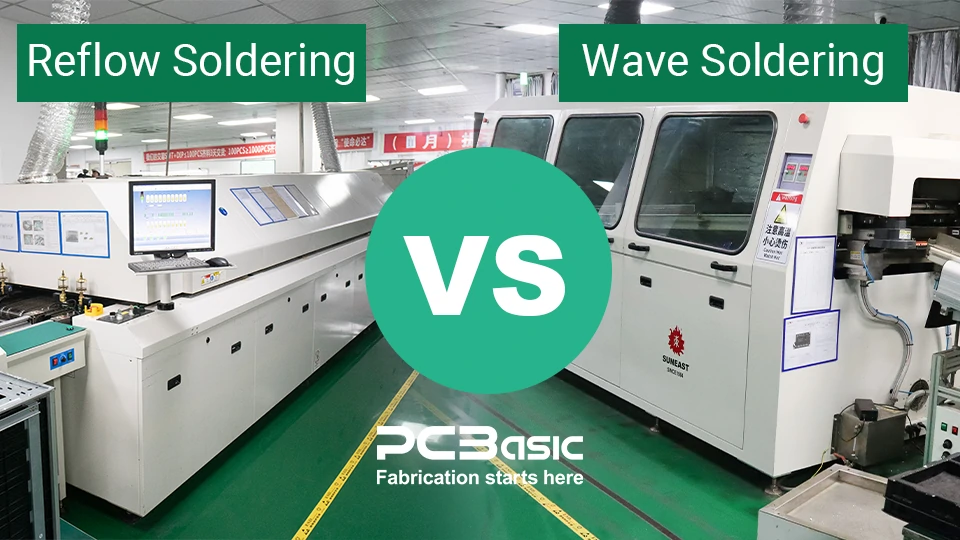

3. Soldering

When component placement is finished, it needs to be permanently fixed to the PCB, a PCBA process called soldering. Common soldering methods include reflow soldering and wave soldering. In reflow soldering, the PCB and components are heated together, and the melted solder paste connects the components to the circuit board. Wave soldering is mainly used for larger components. The solder wave flows through the bottom of the circuit board to complete the soldering. No matter which method is used, the quality of the soldering directly affects the reliability and electrical performance of the circuit board. Every connection in the soldering process must be accurate, which is a particular step in the PCBA process.

4. Inspection and Testing

After soldering, all assembled PCBs are subjected to rigorous inspection and testing. There are a variety of inspection methods, the most common are automatic optical inspection (AOI) and functional testing. AOI is used to automatically check the soldering quality in PCB assembly, while functional testing is used to connect the PCBA circuit board to the device to simulate the actual operating conditions and test whether all functions are normal. These high-precision tests ensure that every circuit board assembler delivers products that meet strict quality standards.

5. Final Assembly

Once the PCBA passes all the tests, it goes through final assembly with other parts of the mobile phone such as the screen, battery, case, etc. In this process, PCBA is integrated into the framework of the phone and a final round of testing is conducted to ensure that the overall performance and functionality of the phone meet the requirements.

Through the above steps, PCBA manufacturing ensures that each circuit board is subjected to strict quality control, and ultimately can provide stable support for devices such as mobile phones.

If you have PCBA manufacturing needs for mobile phones, it is important to choose a reliable and experienced PCBA manufacturer. PCBasic is a leading circuit board assembler in China with extensive experience in the mobile phone PCB assembly industry and focuses on providing high-quality PCBA services, from design to assembly, ensuring that every PCBA process step complies with the highest standards.

As a professional circuit board assembler, PCBasic focuses on providing one-stop service, fast multi-variety and small-batch, high-volume PCBA manufacturer. Its services include R&D solutions, material selection, OEM order production, and so on. The company has independently developed CRM, MES, ERP and Internet of Things management systems to achieve industrial digital intelligent factories.

PCBasic is a trusted PCB manufacturing company, its main service areas include industrial control, smart home, instrumentation, vehicle IoT, mobile devices, medical equipment, automotive electronics, aviation, and more. With more than 15 years of experience in the SMT industry, PCBasic has successfully overcome many challenges. Investment in PCBA technology continues and a range of intelligent production management systems have been developed to improve management efficiency and quality.

At the same time, PCBasic has got ISO9001, IATF16949 and ISO13485 quality certification, and obtained the national high-tech enterprise certification. In terms of quality control, PCBasic adopts self-developed LCR incoming inspection system, SMT fault detection system, sample patch system, MES system, intelligent material racks. In addition, it uses advanced intelligent electrostatic protection systems to ensure that each product is manufactured carefully.

Understanding what PCBA is allows us to realize its indispensable role in mobile phone technology. From connecting components to supporting advanced features such as 5G and AI processing, printed circuit board assembly is the foundation of modern smartphones. The complex PCBA manufacturing process combined with advanced technology ensures that each mobile device can operate reliably in a variety of conditions. And by the way, selecting a reliable mobile phone PCB assembler is the basis for ensuring the quality of your products.

Assembly Enquiry

Instant Quote