Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Get Industrial PCB Assembly Services from PCBasic

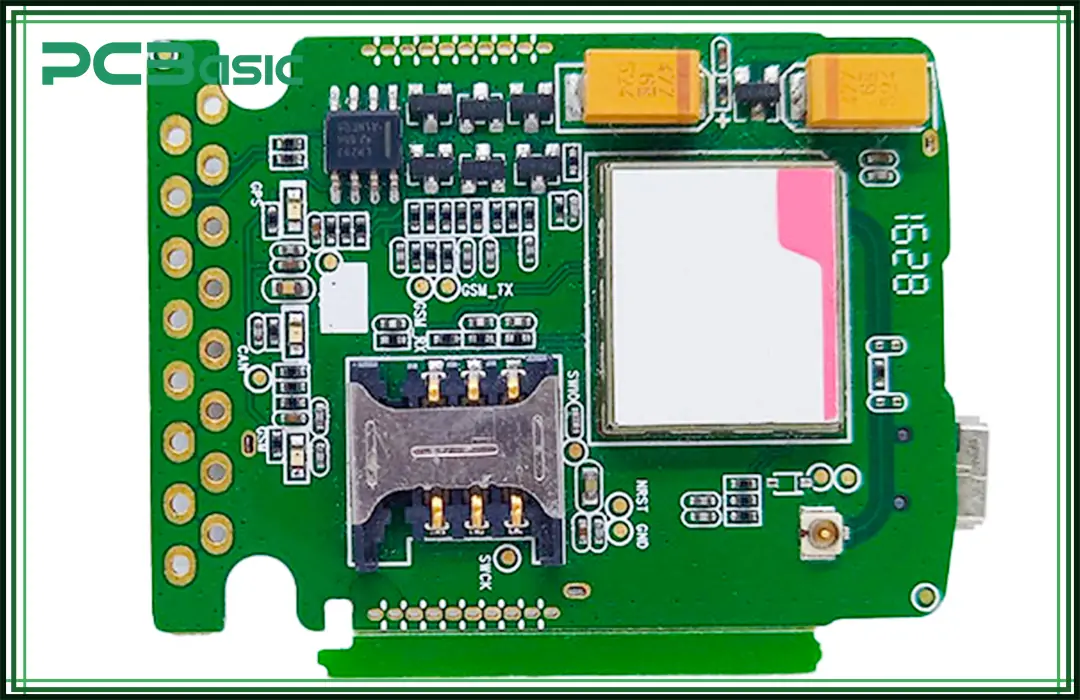

With the fast pace of the contemporary industrial era, high-performance and efficient electronics are a vital part of maintaining machinery, automation systems, and process controls. The core of these systems is industrial PCBs—specialized circuit boards for harsh environments, delivering long-term performance in demanding industrial environments.

When it comes to industrial PCB assembly, PCBasic has gained a reputation as a trustworthy partner providing cost-effective, high-quality assembly work for a wide range of industrial applications. PCBasic supplies robust and precision-assembled PCBs that put critical industrial processes around the world into motion, from automated production lines to energy management systems.

Industrial PCB assembly is assembling and manufacturing printed circuit boards specially designed for industrial purposes. Industrial PCBs are implemented within equipment and machinery that are used in automation, power generation, manufacturing, robotics, transportation, and energy systems industries. Industrial PCBs are unlike consumer electronics because they must be durable to withstand rough operational conditions, including heat and cold temperatures, vibration, dust, moisture, and chemicals.

Durability, reliability, and performance- these are integral qualities needed for industrial PCB assembly, given the worst working environments that such assembly is likely to encounter. Typically, industrial PCB components will be of high-grade quality, and the assembly process will also generally incorporate among its strict quality control measures complicated testing methods, such as X-ray inspection, functional testing, and thermal cycling.

Industrial PCB assemblies come in various configurations:

● One-layer PCBs are for simple applications.

● Multilevel PCBs for complex industrial systems with increased circuit density.

● Rigid, flexible, and rigid-flex PCBs for different design requirements, such as space or flexibility for dynamically moving equipment.

In essence, the industrial PCB assembly produces circuit boards that are configured to be very robust to be able to carry out continuous operation under the rigorous conditions of an industrial environment. The boards are important components of the efficient functioning of industrial processes, automation systems, and heavy-duty equipment.

Industrial PCB assemblies are vital to modern industrial systems, which ensure uninterrupted automation, process control, and efficient power management in multiple industries. These Kind of PCBs are built to withstand the extreme environment usually encountered by heavy machinery, control systems, and high-performance electronics.

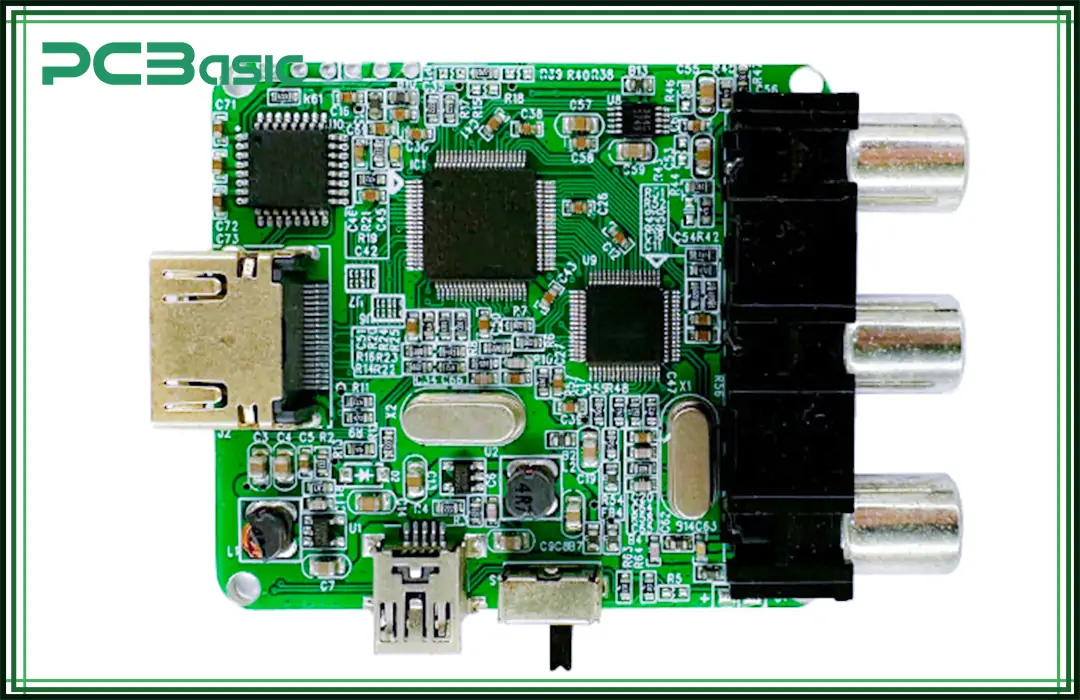

Industrial PCBs are broadly used in automated manufacturing lines, robotic arms, and CNC machines. These PCBs control motor drives, sensors, actuators, and communication, among other machines, in smart factories for accurate real-time operations.

Industrial PCBs perform power conversion, monitoring, and distribution in power grids, renewable energy systems, and power distribution networks. The boards are subjected to high voltage/current loads; therefore, reliability and heat management are critical.

Process control systems in industrial plants are designed to monitor and adjust parameters such as temperature, pressure, flow rate, and composition of the material, which heavily rely on PCBs. These systems use sensor interface PCBs to collect data and control PCBs to act in response, serving to maintain a stable and efficient production process.

Industrial PCBs are embedded inside heavy machinery such as construction vehicles, tractors, and logistics systems. They provide capabilities such as ECU operations, GPS tracking, and diagnostic systems, improving safety, efficiency, and automation.

Industrial testing instruments are used for quality control, material testing, and calibration, while the high-precision PCBs drive that signal processing from sensors to deliver accurate real-time information which is quite important for sustaining product quality and ensuring equipment performance.

Certain industrial PCB assemblies are also adopted in aerospace and defense applications where reliability under extreme environmental stress is critical; examples include navigation systems, avionics, and defense communications systems.

All in all, industrial PCB assemblies become vital for the automation, efficiency, and safety of industrial processes. Their application ranges almost across all manufacturing and energy sectors, hence making themselves indispensable in the modern-day industry.

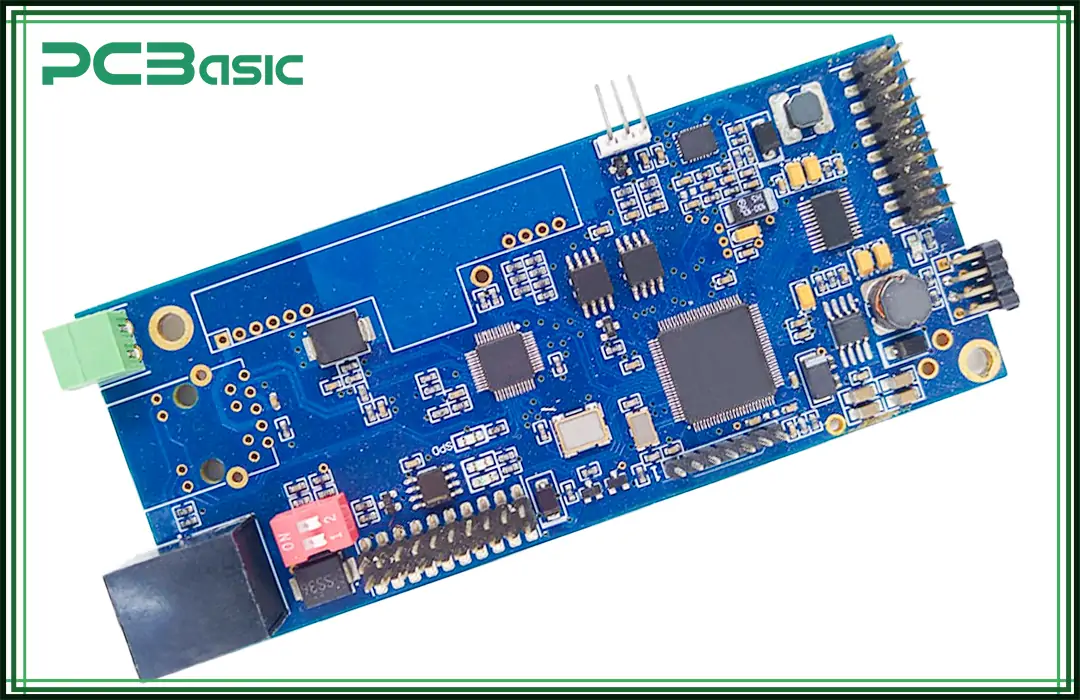

PCBasic is your consummate partner in industrial PCB assembly. With a one-stop destination for total assembly service of industrial-class applications, PCBasic has proven itself to be a trustworthy partner in PCB assembly. With state-of-the-art manufacturing facilities and a skilled engineering team dedicated to delivery at every level prototype to low-volume to high-volume production will meet the highest standards of quality and performance in your industrial PCB Assemblies.

Why Choose PCBasic for Industrial PCB Assembly?

PCBasic has comprehensive services, including:

● Fabrication of PCB-single-layer, multi-layer, rigid, flex, and rigid-flex PCBs.

● Component Sourcing- the right quality industrial-grade components from trusted suppliers.

● Surface Mount (SMT) & Through-Hole Assembly.

● Testing & Quality Control (AOI, functional testing, X-ray inspection).

PCBasic acknowledges the unique requirements of industrial conditions, such as high reliability, robustness, and thermal performance. Whether the PCB is intended for industrial automation, power management, or process control, the PCBasic team ensures that it is designed for high efficiency even in the harshest conditions.

Industrial projects often require custom solutions, and PCBasic is brilliant at offering engineering support to optimize PCB designs for manufacturability and performance. They will work closely with you to meet custom specifications and environment needs.

At the same time that they are high quality, PCBasic's suppliers are also very cost-efficient, making them the ideal partner for organizations looking to budget cost against performance at the highest levels in their industrial electronics.

Industrial projects often have tight timelines, and PCBasic delivers with faster lead times without compromising quality. Their global shipping network makes sure you get your PCBs wherever you are and there will be no compromise in your project.

Combining the finest high-quality manufacturing with expert engineering support and customer-lowering economics, the PCBasic industrial PCB assembly services can run your industry systems efficiently and faultlessly.

The following are some top reasons why you should consider PCBasic as your PCB assembly partner for the success and reliability of industrial electronics.

Extensive experience in industrial PCB projects made PCBasic familiar with the tough environment conditions that industrial electronics have to withstand high temperature, vibration, humidity, and electrical noise.

Everything is done under one roof:

● PCB Fabrication-one layer to multi-layer boards

● Component Procurement-industrial-grade components from trusted sources

● PCB Assembly-SMT, through hole, and mixed technology

● Testing and Quality Inspection

Incorporating everything reduces lead times and streamlines your supply chain.

In industrial applications, quality is not negotiable. PCBasic complies with international standards (like IPC-A-610) and uses state-of-the-art inspection approaches to make sure that each assembly adheres to stringent industrial requirements. Their verification process, which is done in several steps, confirms the performance of your boards in the field.

Each industrial project is unique, and custom solutions are provided by PCBasic to meet their specific requirements. Their engineering team works closely with you to optimize designs for performance and manufacturability, whether it is special materials, unique layouts, or enhanced thermal management.

PCBasic offers competitive pricing compared to others without compromising on quality, making them stand out from the crowd.

It is critical to meet production deadlines in industrial projects. PCBasic provides quick-turn assembly services that do not compromise on quality. They ship globally so that assemblies may meet installed destinations wherever the facility may be located.

PCBasic is recognized amongst industrial equipment manufacturers, automation companies, and energy firms all over the world. Some big names includes Intel, Huawei, vivo and more. Such a reputation is earned with consistent quality, reliability, and customer service making PCBasic the preferred partner for several industrial sectors.

When it's about industrial PCB assembly, having a good partner makes all the difference in terms of reliability, performance, and cost-efficiency. PCBasic has asserted itself as a trustworthy name in the industry, offering complete PCB solutions for industrial applications. It covers all processes from high-end fabrication and faultless assembly, rigorous testing, and global delivery to help ensure that your industrial electronics withstand harsh conditions and maintain reliable performance. So, offering everything under one roof.

For any industrial-level applications such as automation systems, power distribution equipment, and industrial sensors, PCBasic stands out with expertise, modern technology, and a customer-oriented approach, making it the perfect industrial PCB assembly partner. With PCBasic, you keep in mind your investments in quality, reliability, and long-term success for your industrial projects.

Assembly Enquiry

Instant Quote