Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Capabilities for Micro BGA Assembly from PCBasic

With the continuous miniaturization of electronic devices, the demand for high-precision BGA circuit board assembly is increasing. With the continuous development of BGA technology, Micro BGA assembly has become an indispensable process in modern electronic products. As a leading PCB assembly manufacturer in China, PCBasic, having advanced capabilities and equipment, is a trusted brand in the field of BGA assembly.

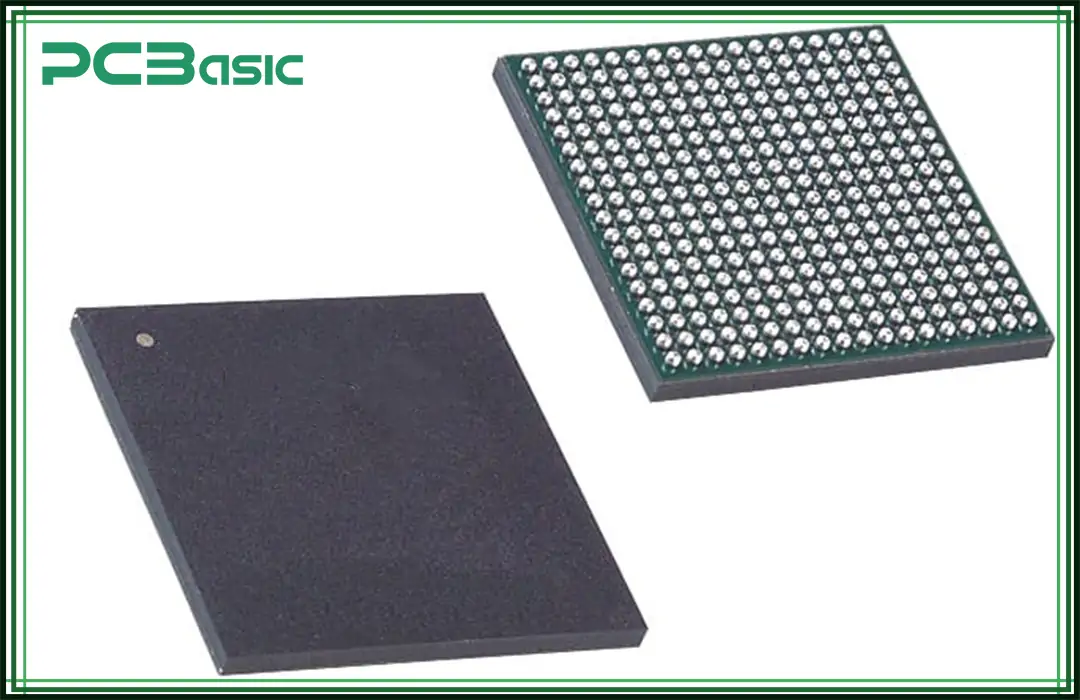

Before we understand Micro BGA assembly, let's first understand one question: What is BGA? BGA (Ball Grid Array) is a surface mount packaging technology that enables electrical connection by using a set of solder balls. Traditional packaging technology uses pins to connect the circuit board, while BGA packaging arranges multiple small solder balls in a grid pattern, which not only increases the connection stability of each solder point but also improves signal transmission and heat dissipation. BGA packaging is commonly used in electronic products that require high density, fast transmission and high performance, such as microprocessors, memory chips and other high-frequency electronic devices.

Micro BGA is to further shrink BGA technology by reducing the ball spacing so that the density of the component is higher. This miniaturized BGA packaging is particularly suitable for smartphones, wearables, and high-end computer systems.

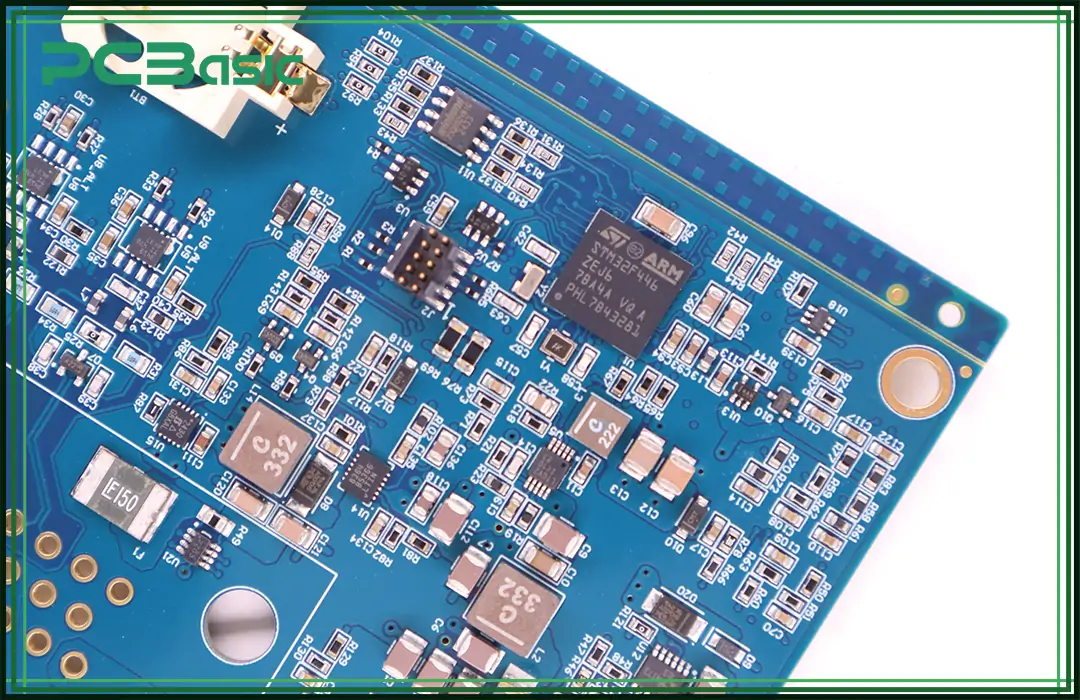

Micro BGA Assembly usually refers to the process of assembling BGA packaged chips onto a circuit board, which mainly involves Micro BGA chips, PCB boards, solder paste printing, pick-and-place, reflow soldering, and X-ray inspection. Micro BGA Assembly mainly assembles BGA packaged chips on PCB boards rather than separately assembling the BGA itself. It is a part of PCBA and is a high-precision and difficult soldering process on the SMT production line.

Compared with traditional packaging types, the advantages of micro-BGA assembly are outstanding:

Enhanced Performance: Micro BGA packages have better conductivity and thermal dispersion than traditional surface mount technologies such as SMD. The solder points of the BGA are evenly distributed, which makes the signal transmission more stable. At the same time, the solder ball area of the Micro BGA is larger, which can carry more current and reduce the overheating phenomenon.

Compact Design: One of the biggest advantages of the Micro BGA packaging is its extremely compact design. Compared to traditional BGA packaging, Micro BGA has smaller ball spacing and is able to fit more electronic components in a limited space, which is critical for modern electronics such as smartphones, tablets and other high-performance devices.

Improved Reliability: The Micro BGA adopts the ball grid array solder technology, and the solder points are evenly distributed to form a strong electrical connection. Due to this design, the strength of the connection is greatly increased, reducing the risk of poor contact.

Better Signal Integrity: The Micro BGA package design allows for more uniform current transmission at each solder point, reducing electromagnetic interference (EMI) and signal reflection. Due to the design of the ball grid array, the signal transmission path becomes shorter and straighter, reducing transmission delays and signal losses, and thus performing better in high-speed signal processing and data transmission applications.

In general, Micro BGA packaging not only improves the performance and reliability of electronic products, but also achieves higher density integration in a limited space, and optimizes production efficiency, it is an indispensable packaging technology for many high-end electronic products.

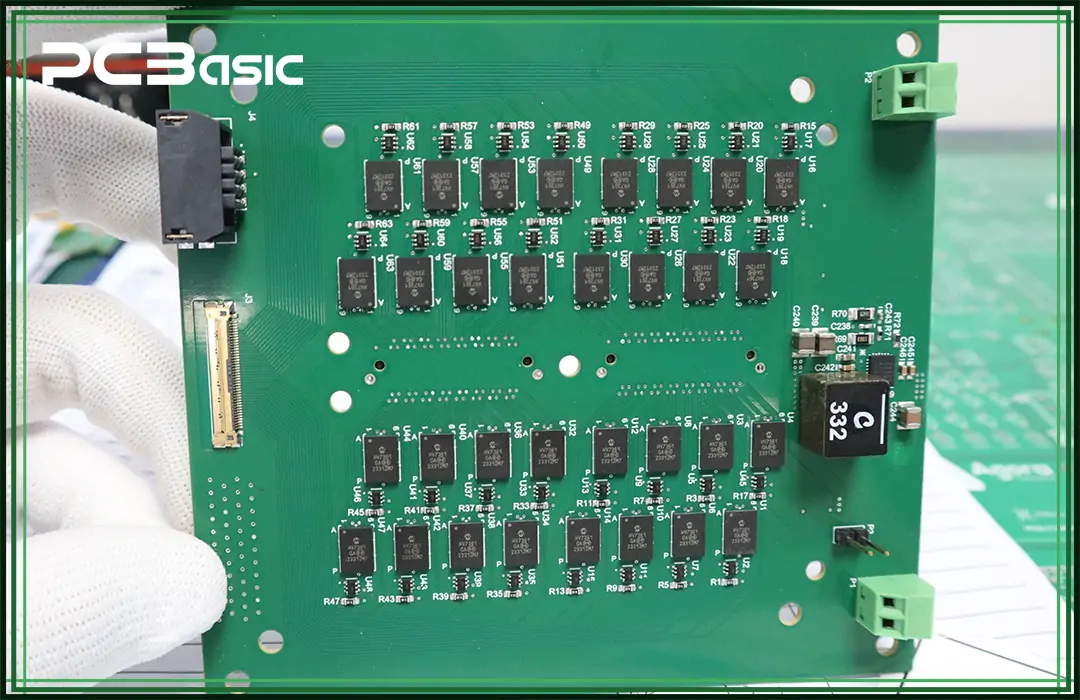

As a leader in BGA assembly, PCBasic offers cutting-edge capabilities tailored to the needs of modern electronics manufacturing. Its advanced equipment and rich BGA circuit board assembly experience, as well as high-end inspection equipment, ensure excellent manufacturing standards.

1. Over 10 Years of PCB Design and Project Management Experience

Its team has deep expertise in BGA circuit board design and production, ensuring high reliability and precision.

2. Advanced Testing and Quality Assurance

With X-ray inspection and a self-developed SMT fault detection system, PCBasic ensures defect-free BGA assembly.

3. State-of-the-Art Manufacturing Facilities

PCBasic operates multiple PCBA factories, including Shenzhen Small-Batch Factory – Ideal for prototyping and specialized BGA electronics production, and Huizhou Large-Batch Factory – Dedicated to mass production of BGA packages with consistent quality.

4. Precision Stencil and Fixture Production

PCBasic’s self-operated factory provides stencils within 1 hour to streamline BGA assembly processes.

5. Intelligent Supply Chain Management

With an intelligent electronic components central warehouse, PCBasic guarantees the availability of original and genuine parts.

6. Industry Certifications and Compliance:

PCBasic is ISO13485, IATF 16949, ISO9001, ISO14001, and UL certified, ensuring the highest quality standards in BGA electronics manufacturing.

7. Innovative Digital Factory Systems

Its self-developed CRM, MES, ERP, and IoT management systems enhance production efficiency and quality control.

The rise of compact and high-performance devices has made technologies like Micro BGA assembly critical in modern electronics manufacturing. By leveraging its extensive expertise, advanced facilities, and innovative processes, PCBasic delivers unparalleled solutions tailored to the needs of industries relying on cutting-edge BGA technology. Whether you need precision in handling complex designs or reliability in mass production, PCBasic ensures excellence at every step.

For businesses seeking robust solutions in BGA assembly, PCBasic stands out as a leader capable of transforming ideas into reality with speed and precision.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.