Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What is CNC Fabrication?

In simple words, CNC fabrication incorporates computer-controlled machines to make parts. CNC operators use complex designs to make custom parts using 3-axis and 5-axis CNC machines. This process is now very important for many industries. We will explain what it is. We will also talk about the different machines. And we will describe how it all works.

So the grim fact here is, what is CNC fabrication? CNC stands for Computer Numerical Control. That does mean computers run the machines. These machines slice, form or create things. It is not the direct human controlling the machine. Instead, you enter instructions into a computer. The machine then gets directed by the computer.

CNC fabrication gives very accurate results, and engineers know it. It also makes the exact repetition accurate. This point is essential. If a part is machined with CNC, it will closely match the design. If you need thousands of the same part, they will all be highly similar.

A brief definition of CNC fabrication. What is CNC fabrication? Well, first, you are going to need a design. In general, this design is done on a computer. This uses CAD software. CAD (Computer-Aided Design) is a technology used for design and documentation. That design is then converted into instructions. These instructions specify the actions the CNC machine should take. The machine knows where to move its tools. It also knows how quickly to move them.

The next thing is that, as you can see, there are a variety of CNC machining machines. Each has its benefits for specific tasks. Here are some common types:

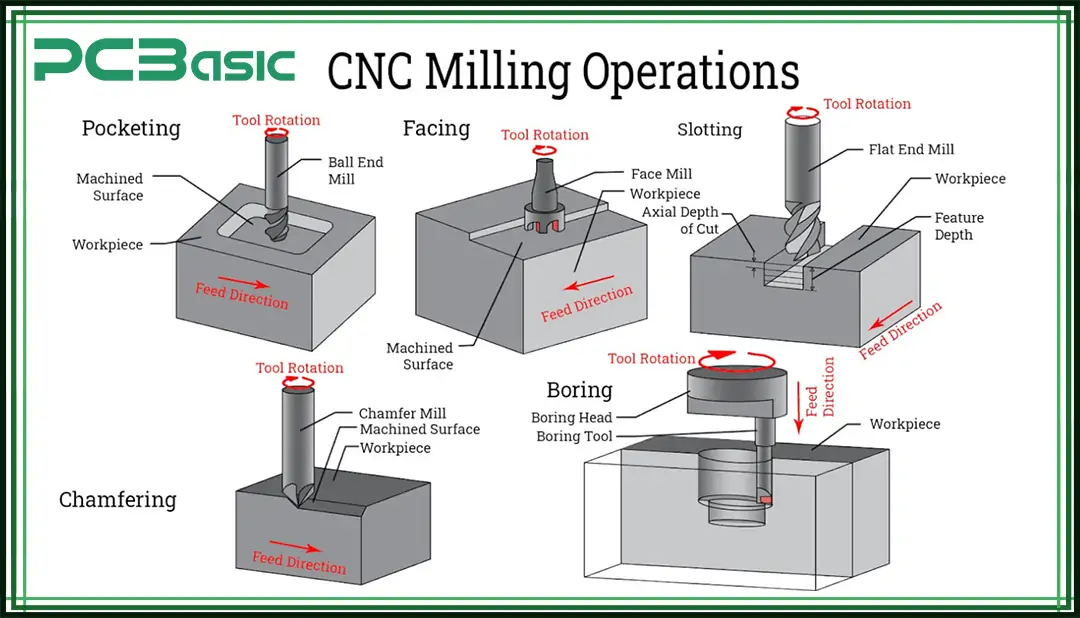

These machines spin tools to remove material. They can make complex shapes. Moreover, many different tasks can be performed using them. Let us discuss further CNC milling machines. These can maneuver the cutting tool on various axes. It lets them make really complicated three-dimensional shapes. There are many variants that you will get to know as a milling machine. Some can move along three axes (X, Y, and Z). Some have many more, providing the potential for even more complexity.

Lathes spin the material. The tool then takes away parts of it. These are typically used for round or planar components. Shafts, bolts, discs – all typical workpieces produced on a CNC lathe. Its spinning action allows round features to be easily formed as well. A lathe can use different tools to carry out processes such as facing, turning, and also threading.

These are similar to milling machines. But they usually slice through softer materials. This can be wood, plastic and composite materials. They can also handle larger pieces. CNC routers are commonly used in sign-making and woodworking. They can quickly and accurately cut large sheets of material. They also serve the purpose of creating molds and prototypes made of softer materials.

These machines cut metal with super-hot, fast-moving plasma. That includes steel and aluminum. The CNC plasma cutter is very efficient in cutting thicker steel plates. These are commonly utilized in fabrication shops to manufacture structural components and machined parts.

It uses a focused beam of light to cut or engrave materials. They can be worked on with a lot of materials. Examples are metals, plastics, and wood. Laser Cutting with a CNC workshop offers extremely high precision and clean cuts. They are utilized for cutting thin sheets of metal (to incorporate into electronics) to etching highly detailed patterns onto wood or acrylic.

These machines use a powerful jet of water. Sand or other abrasives are sometimes added. The water can also slice through many different materials. They work well for materials that may not get too hot. An important feature of CNC waterjet cutter machines is that they don't produce heat. Therefore, they are suited to cutting heat-sensitive materials. They can also slice through extremely thick materials, such as stone and glass.

This is key. The types of CNC machines depend on the material you are using. They also vary by the shape of the part you want, and that depends on how accurate it needs to be.

So how is CNC workshop machining done? Here are the usual steps:

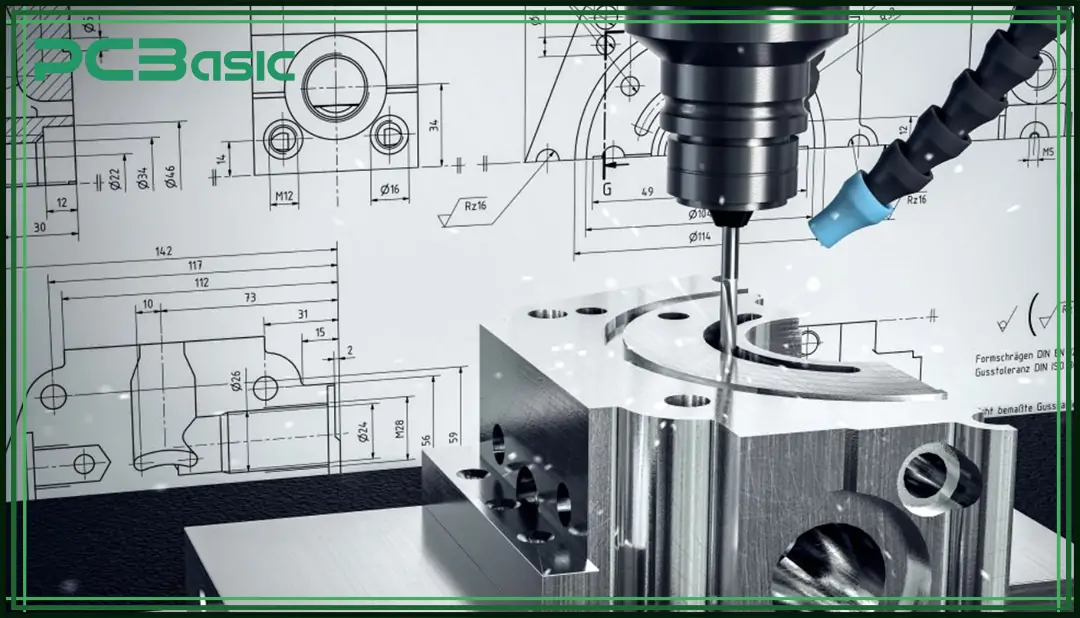

First, you create a design. This can be a 3D model or a 2D drawing, and you use CAD software to do this. Now, let’s discuss the design process in detail. Engineers use CAD software to create highly detailed, accurate models of their parts. Of note, this is crucial for upholding the specifications of the final result.

The CAD design is brought into CAM software. CAM — Computer-Aided Manufacturing: This creates the instructions for the CNC machine. These instructions tell the machine how to operate its tools. Then they can fix the cutting speeds and other details. The next step in CAM programming is critical for machining optimization. The CAM software assists in establishing the best toolpaths and cutting strategies, which saves time and improves the quality of the final part.

You select the appropriate cutting instrument, which is punched into the CNC machine. From there, you bring the raw material, which is called the workpiece. You clip it onto the machine and lock it in. It is also important for the safety and the proper functioning of the machine that it is set up correctly. The cutting implements must be sharp and correctly aligned. The part is better secured and held within the machine so it does not move during machining.

The CNC machine computer loads the program from the CAM software. When the operator turns it on, the machine operates according to the program designed. It drives the tools for cutting the material and building the part. At the same time, the machine often leverages sensors while working. These sensors monitor the process. If necessary, small adjustments to the graphic can be made. This ensures that the part is precision-accurate and high-quality.

After the machine is finished running, the part may require some finishing. This might involve smoothing out sharp edges or applying some sort of polishing or top coat, an aesthetic treatment that makes the part look and work as expected. Finishing operations may encompass several processes, such as sanding, bead blasting, painting, or plating. These processes are key to obtaining the appropriate finish and providing a wear- and corrosion-resistant surface on the tool.

During the execution phase, the CNC machine literally follows the pedagogy step-by-step. The computer controls the speed and accuracy of the machine's movements. So, that ensures the part is made right based on design.

You will notice that there are multiple common methods of CNC machining. These serve to create different outcomes:

Milling relies on a rotating tool with multiple cutting edges. As you know , this tool removes material to form shapes. It can produce smooth surfaces and intricate three-dimensional shapes. Let's examine milling more closely. There are different classes of milling operations, such as black milling, end milling, and profile milling. Both are used to create specific features on a part.

In turn, the material spins rapidly while a stationary tool removes the material. An end mill traverses it, subtracting material. This produces round components with characteristics such as threads and grooves. Turning is an important machining process for producing cylindrical parts. Rough turning, finish turning, and parting off are different types of turning operations.

It makes holes with a revolving drill bit. CNC machines can also drill very precise holes of various diameters and depths. Drilling is a routine operation for manufacturing holes for fasteners or other applications. CNC workshop machines can also perform drilling operations at specified locations and depths.

This expands and sharpens an existing hole. It provides higher precision than drilling. Boring is frequently performed at the last step of machining to confirm the roundness and size of the holes.

This does internal threads in a hole. This allows you to screw the bolts or other fasteners into it. Tapping is the operation of creating threaded holes for mating parts to be assembled with screws or bolts.

Grinding machines are CNC machines that use abrasive wheels to remove tiny bits of material. This results in very exact sizes and smooth surfaces. Grinding machines are commonly used for hard substances. There are many types of high-precision machining processes, but from a specific perspective, the global survey is either grinding or law.

There is no doubt that CNC fabrication plays an important role in the electronics industry. Why does it matter? Because electronic components are usually required to be quite precise and quite small. Here are some uses:

PCBs have millions of tiny holes drilled in them by CNC fabrication machines. These holes are for placing components and routing electrical signals on the boards. Now, consider a PCB with small holes. The holes must be precisely in the exact location, which CNC machines can do extremely well. This layout provides proper connectivity for all electronic components.

Electronics require precise boxes, and CNC machining does just that. These boxes are well-sized and protect the contents. Because the sensitive components inside an electronic enclosure need to be protected, they must fit precisely. Tight tolerances in CNC machining allow enclosures to have a fit that is snug.

Heat sink machining is a discipline of CNC fabrication. Heat sinks cool electronic components and tend to feature complex shapes that CNC fabrication machines can easily manufacture. Heat sinks usually have complex fin patterns to increase the surface area available for cooling. CNC machines can easily make these shapes.

CNC is used to create a lot of little electronic components as well. That's because it is very good at doing that. To get the complete electrical contact for tiny electronic connectors and components extremely high precision is necessary. You can get the required accuracy from CNC machining.

CNC machines are often used for CNC prototype electronic devices. This allows engineers to try out their designs before producing hundreds of them. Prototypes are crucial for developing new electronic products that are tested and refined. CNC fabrication makes it straightforward and quick for an engineer to create prototypes using a high-accuracy machine.

When they need very accurate electronic parts, customers are so right in their opinion. CNC fabrication establishes that precision.

We are PCBasic and one of the best CNC fabricators in China. Years of excellent CNC fabrication services. We hear you loud and clear, but we like to concentrate on the accuracy and dependability of parts. We produce them the way that you require them.”

We have several advanced CNC machines and an efficient team of engineers and technicians. We can work with various materials, including metals such as aluminum, steel, and brass. We also use ABS, PC , and acrylic plastics, as well as composites.

We offer CNC milling, CNC turning, CNC routing, and other services. We partner with our customers very closely. We take a step from the design to the realization of the final product. We want to ensure that we can fulfill all of your needs. We understand that accuracy and on-time delivery are crucial. We are dedicated to providing you with high-quality service.

If your designs are complicated, do not panic. If you have a vague idea of where to start, we can help you prepare them for manufacturing. Our policy is to be honest and direct. We want to establish lifelong relationships with our customers.

So, as you can see, CNC fabrication is a very viable manufacturing method. It uses computers to manipulate machines. It does this very precisely, everywhere. Very critical in many industries, such as electronics. This is due to the fact that it is accurate, repeatable, and can create complex shapes.

At PCBasic we enjoy being industry top CNC Fabrication Workshop in China. We are always here to assist you with any CNC milled machined parts you may require. The fact that machines do the work does not mean we care less about quality. Pretty awesome, right? As you can see our CNC fabrication capabilities are unparalleled and we would be more than happy to accommodate your precision CNC machining needs. We are excited about the possibility of working with you.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.