Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

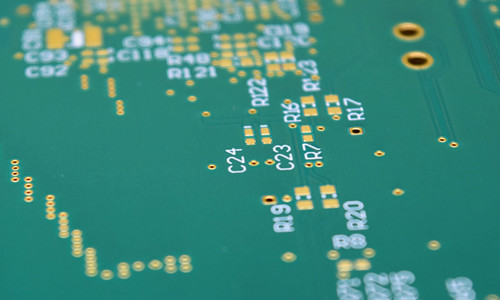

High-TG PCBs come in a variety of different specifications. The choice will depend on the specific application. For instance, the number of layers is important, and you might want to stick with an even number. Then there's the thickness, which depends on whether you're using a rigid or flexible board. Whether you choose to have an even or odd number of layers is up to you, but make sure that the spacing between layers is uniform.

High-Tg PCBs are commonly used in high-temperature applications. These PCBs are made to resist the effects of high temperatures. Unlike standard printed circuit boards, high-Tg PCBs can withstand temperatures up to 280°C. This means that they're better suited to high-temperature applications than standard PCBs.

High-TG PCBs have several advantages. Aside from being highly durable, they're also able to meet RoHS compliance requirements. They're also ideal for electronics that require low working and thermal loads. You'll want to make sure that the circuits you use are built with high-Tg PCBs if you want to ensure maximum performance.

High-Tg PCBs offer excellent mechanical and chemical resistance. This type of PCB material is used in a variety of industries, including automotive electronics, medical devices, and communication equipment. They also offer better adhesion and water absorption. These characteristics make them a superior choice over standard PCB substrate materials.

High-TG PCBs has many pcb colors can be customized!

Copper weight is one of the most critical considerations in high-tg PCB design. It affects the thermal profile of the resulting device. If the copper weight is high, the board will absorb heat quickly. A heavier copper weight, however, can be more expensive. The cost is dependent on process engineering, labor, and Quality Assurance.

High-TG PCBs are made with a Tg of 170 or greater. They are commonly used in instruments, computers, and other high-tech equipment. Copper weight plays a key role in determining the final thickness of the circuit board. The weight of copper in a high-TG PCB is directly proportional to its copper content.

High temperature conditions are particularly harmful for unprotected PCBs. Excessive heat can damage the dielectrics and conductors and create mechanical stresses. This can lead to inconsistency in performance or even failure. High-temperature-resistant PCBs can withstand higher operating temperatures and improve reliability. Lead-free PCBs have a higher Tg than their tin-lead counterparts, which allows them to withstand higher temperatures without any issue.

TG PCB has different surface finishes. Lead-free HASL is cheaper and has a longer storage life. Lead-free soldering can also be used. OSP is simple and inexpensive and is an excellent choice for high-tg PCBs. However, it cannot be used in conjunction with line binding and crimping technologies.

High-TG PCBs are composed of two basic materials: substrates and laminates. The substrates are composite structures with dielectric properties. These are usually made of a glass or paper weave and epoxy resin. They may also contain ceramics to increase their dielectric constant. Laminas, on the other hand, are made up of paper or cloth layers fused together under pressure.

The Thermal Growth Temperature of the PCB plays a significant role in the board's mechanical performance and interconnect reliability. As board technology advances, the Tg increases. For example, copper weights and microvias are becoming more common, as are multiple surface finishes. In addition, the Td is an important measure of thermal resistance. A board that has a high Td will perform better than one that does not.

The temperature range required for PCB lamination is determined by the materials used. The materials used should have low thermal expansion to minimize the chances of dimensional change or thermal stress. Another important factor is thermal conductivity, which is the ability of the material layer to carry heat. If the material is prone to decomposition, it should be avoided.

High-TG PCBs can be single-sided, double-sided, or multi-layered. The design of the PCB is also important.

High-Tg PCB is a special type of PCB that is specifically designed to withstand high temperatures, moisture, and harmful chemicals. This type of PCB is ideal for many high-power electronic appliances. Its superior heat resistance is a significant advantage because it prolongs the life of your electronic device. In addition to this, high-Tg PCBs offer better adhesiveness and dimensional stability.

High-Tg PCB is a versatile material that is widely used in the electronics industry and in the manufacture of instruments and precision apparatus. The material's resistance to high temperatures increases its functionality and resiliency to moisture, chemical exposure, and electrical shock. The PCB's thickness, power density, and size are all impacted by its resistance to heat.

There are different types of surface finishes available for TG PCB. The first one, called HASL, is a lead-free coating that is cheaper and has a longer shelf life. Another type, called OSP, is easy to apply and inexpensive. However, it can't be used with line binding or crimping technology.

High-Tg PCBs are often used for high-density applications. They generate more heat than standard circuit boards, which means that they must be resistant to heat. High-Tg boards are especially suitable for circuits that operate at temperatures of more than 150degC.

High-Tg PCBs are a class of PCB that exhibits good chemical resistance. This property relates to the amount of resistance a PCB material exhibits to methylene chloride in the presence of moisture. The resistance level is generally measured in pounds per linear inch.

High-Tg PCBs have a Tg value of 170 or higher. These PCBs are used in various applications, such as in computer systems, communication equipment, and instruments. They are also widely used in the automotive industry. High-Tg PCBs also show good performance under high temperatures due to their superior stability.

A high-TG PCB will have electrical properties of about 800 V/mil and 1500 V/mil. When subjected to high temperatures, PCB substrates can lose five percent of their mass. Since the effects of this temperature change are permanent, it is crucial to select a material with the proper electrical and thermal properties.

High-Tg PCBs are usually made of thick copper, and are used in high-temperature industrial applications. The thick copper allows for faster battery charging. In addition, they can withstand high current and are used in electric drills, presses, and measuring equipment.

High-Tg PCBs are used in high-temperature applications, including computers and communication equipment. These boards are characterized by high thermal resistance and fine wiring. Additionally, they are resistant to moisture and chemical reaction. High-Tg PCBs are especially beneficial for lead-free pcb assembly.

High-Tg PCBs are more expensive than ordinary PCBs, but they are more durable and offer better thermal, chemical, and mechanical properties. This means less chance of board failure when operated in hot and cold environments. High-density circuit boards can generate a lot of heat, and high-Tg materials are necessary to prevent board failure. Additionally, boards with high Tg materials are typically used in applications with high-temperature tolerance, including those for military and aerospace equipment.

High-Tg PCBs are ideal for transmitting signals with high frequency and high current. Typically, these boards must be made with thick copper and wide traces. In addition, they should have low thermal conductivity. This will prevent pad lifting and prevent cracks in corners and vias.

High-TG PCBs come in two basic types: custom high-TG PCBs and module-based high-Tg PCBs. Custom PCBs are designed according to specific customer specifications. In addition, they can also be modified based on customer requirements.

Welcome to China PCB Online Purchasing!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.