Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Top 10 Automation Technologies in the PCBA Field and a Market-Leading Company

The rapid advancement of automation in the PCB Assembly (PCBA) industry has revolutionized manufacturing processes, leading to faster production times, higher accuracy, and cost reductions. Automation technologies have played a crucial role in ensuring the precision and reliability of electronic assemblies. Below, we explore ten key automation technologies in the PCBA field, along with leading companies that have set the benchmark for innovation and efficiency.

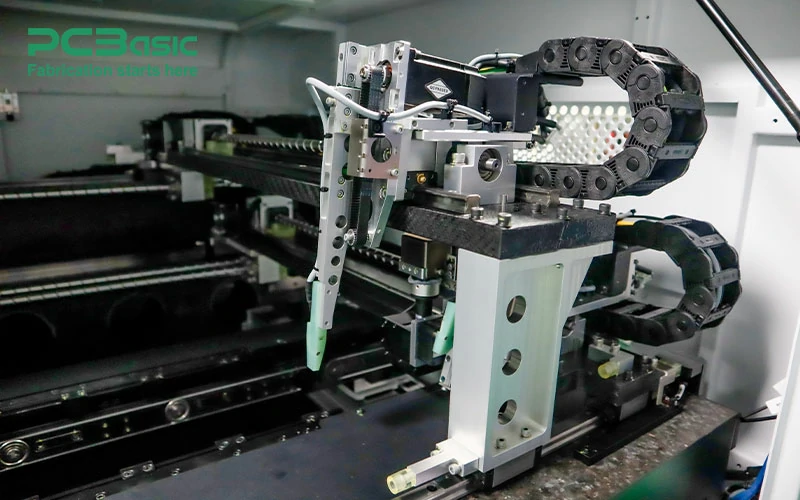

Pick and place machines are at the core of the automated assembly process. These machines are responsible for placing surface-mount components (SMDs) onto printed circuit boards (PCBs) with extreme precision. They use robotic arms or other automated mechanisms to pick up components from reels or trays and place them onto the board. These machines significantly improve production speed and reduce human error.

Reflow soldering is an automated process that uses heat to melt solder paste and form reliable solder joints between the PCB and its components. The process involves passing the PCB through a temperature-controlled oven where the solder paste melts, bonds components to the PCB, and then solidifies as the board cools.

Wave soldering is used primarily for through-hole components. The PCB is passed over a wave of molten solder, ensuring the solder is applied to the through-hole pins. This process is highly efficient for high-volume production.

Automated Optical Inspection (AOI) systems are crucial for ensuring quality control in PCBA. AOI systems use high-resolution cameras and artificial intelligence to inspect solder joints, component placement, and other aspects of the PCB assembly. These systems quickly detect defects such as misaligned components, soldering defects, and open or short circuits.

X-ray inspection is used to inspect solder joints in areas that are difficult to access through conventional methods. It is especially useful for inspecting hidden or under-the-component solder joints, which are common in complex, multi-layered PCBs.

Flying Probe Testing (FPT) is an advanced testing method used for checking the electrical integrity of PCBs. Unlike traditional bed-of-nails testing, which requires custom fixtures, FPT uses robotic probes to make contact with the PCB at specific points. This method is ideal for small to medium production runs and prototype testing.

Solder Paste Inspection (SPI) is a critical process that ensures the correct amount of solder paste is applied to the PCB before component placement. SPI systems use 3D imaging technology to measure the volume, height, and position of the paste deposits.

Automated component insertion machines place through-hole components into PCBs before the wave soldering process. These machines ensure that components are accurately positioned and inserted at high speeds.

Conformal coating is applied to PCBs to protect them from environmental factors such as moisture, dust, and chemicals. Automated conformal coating systems ensure uniform application of the protective layer, enhancing the durability and reliability of the assembly.

Automated Function Testing (AFT) ensures that the assembled PCBs are functioning correctly before they leave the production line. AFT systems simulate real-world conditions to test the electronic components and ensure they operate as intended.

At PCBasic, we take pride in being a leading PCB and PCBA manufacturer with over a decade of experience and innovation in the electronics industry. Founded in Shenzhen, China in 2011, our commitment to speed, quality, technology, and service has helped us stand out in the competitive global market. Our mission is to provide our customers with the most reliable, high-performance electronic solutions, whether it's for prototyping, small-batch production, or mass production.

PCB Manufacturing

We specialize in the fabrication of single-layer to multi-layer PCBs, offering advanced capabilities to meet the needs of even the most complex and high-performance PCB designs.

PCB Assembly (PCBA)

Our turnkey PCB assembly services include both SMT (Surface Mount Technology) and THT (Through-Hole Technology), ensuring a seamless assembly process from design to delivery. Whether it's prototype assembly, small-batch production, or large-scale mass production, we are here to serve you.

Custom Design and R&D Support

We offer PCB design and layout services with a keen eye on ensuring manufacturability. Our engineering team conducts thorough DFM (Design for Manufacturability) reviews to ensure your design is optimized for production efficiency.

Material Procurement

With a stable and reliable supply chain, we ensure the procurement of high-quality, RoHS-compliant materials, guaranteeing that your PCBs and assemblies meet industry standards.

Testing and Quality Assurance

At PCBasic, quality is our top priority. Our advanced inspection systems—including flying probe tester, AOI (Automated Optical Inspection), X-ray, SPI (Solder Paste Inspection), and functional testing—are integral to our rigorous testing process.

Our self-developed quality control systems, such as LCR inspection, ensure the highest level of component quality and overall assembly integrity.

We are proud to be at the forefront of intelligent manufacturing with our smart factory management systems, such as CRM, MES, ERP, and IoT integration. We employ cutting-edge tools like ESD protection systems, intelligent material racks, and CNC machinery to ensure precision, efficiency, and quality in every stage of production.

One of the key advantages of working with PCBasic is our commitment to automated processes, especially the flying probe testing machine. The flying probe tester is one of the most advanced quality control tools in our facility. Unlike traditional testing methods, the flying probe system offers unparalleled accuracy and flexibility, enabling us to perform in-depth electrical testing of PCBs without the need for custom fixtures. This makes it ideal for small to medium production runs or prototyping, ensuring that even the smallest defects are caught early, saving you both time and costs.

At PCBasic, we work with clients across a variety of industries:

· Industrial control

· Smart home technology

· Medical devices

· Automotive electronics

· Aerospace

· Internet of Things (IoT) and communication equipment

We are proud of our achievements and certifications, which reflect our dedication to quality and continuous improvement:

· ISO9001, IATF16949, and ISO13485 certifications.

· Recognized as a national high-tech enterprise in China.

· Holder of over 20 patents for software and testing equipment.

· Over 96% on-time delivery rate: We understand the importance of timely delivery and work diligently to meet your deadlines.

· Seamless one-stop service: From design to final delivery, we offer a streamlined service that makes the entire process easy for you.

· Custom-tailored solutions: We understand that every project is unique. Our team works closely with you to provide solutions that fit your specific needs.

· Transparent processes: With real-time production monitoring, you can trust that your project is being handled with care and precision at every step.

We pride ourselves on our 24/7 customer service and flexible production options, with no minimum order quantity (MOQ) required. Our commitment to customer satisfaction extends to ESD-protected packaging and strong, reliable global logistics partnerships to ensure your products reach you safely, no matter where you are.

PCBasic’s commitment to innovation, quality, and customer satisfaction has positioned us as a market leader in the PCB and PCBA industry. Our state-of-the-art facilities and cutting-edge technologies, including the flying probe testing machine, set us apart as a partner that understands the importance of precision and reliability in your products.

We look forward to helping you bring your designs to life with our intelligent manufacturing solutions and exceptional customer service. Whether you're a startup or a global enterprise, PCBasic is here to provide you with the best solutions in the PCB and PCBA industry.

Assembly Enquiry

Instant Quote