Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > The Role of a Surface Mount Device Distributor in the Electronics Industry

The electronics industry relies heavily on surface mount technology (SMT) to produce modern electronic products. From smartphones to automotive components, SMT assembly ensures precision and efficiency in PCB assembly. However, at the heart of this advanced technology is the availability of high-quality surface mount devices (SMDs) and the role of surface mount device distributors.

In this blog, we’ll explore the importance of SMD distributors, their role in SMT PCB assembly, and how they support the growing needs of SMT production lines. We’ll also delve into how these distributors ensure the seamless supply of electronic components, SMT equipment, and SMT supplies.

A surface mount device distributor specializes in providing SMDs and related electronic components to manufacturers and assembly facilities. These distributors bridge the gap between component manufacturers and electronics companies, ensuring a steady supply of materials required for SMT assembly.

Key roles of an SMD distributor include:

1. Component Sourcing: Providing high-quality surface mount devices such as resistors, capacitors, and chip electronics.

2. Supply Chain Management: Ensuring a reliable flow of components to SMT production lines.

3. Support for SMT Equipment: Offering accessories and consumables for SMT machines and PCB equipment.

Surface mount devices are the backbone of modern electronics manufacturing. Unlike traditional through-hole components, SMDs are designed to be mounted directly onto the surface of a PCB. This design supports smaller, faster, and more efficient electronic products.

The availability of SMDs impacts every SMT production line, from design to final assembly.

The success of an SMT production line depends on the timely availability of electronic components. SMD distributors ensure manufacturers have access to a vast inventory of surface mount devices, from chip electronics to advanced integrated circuits.

SMD distributors often supply essential materials for SMT PCB assembly, such as solder paste, stencils, and adhesives. These materials are critical for the efficient operation of SMT machines.

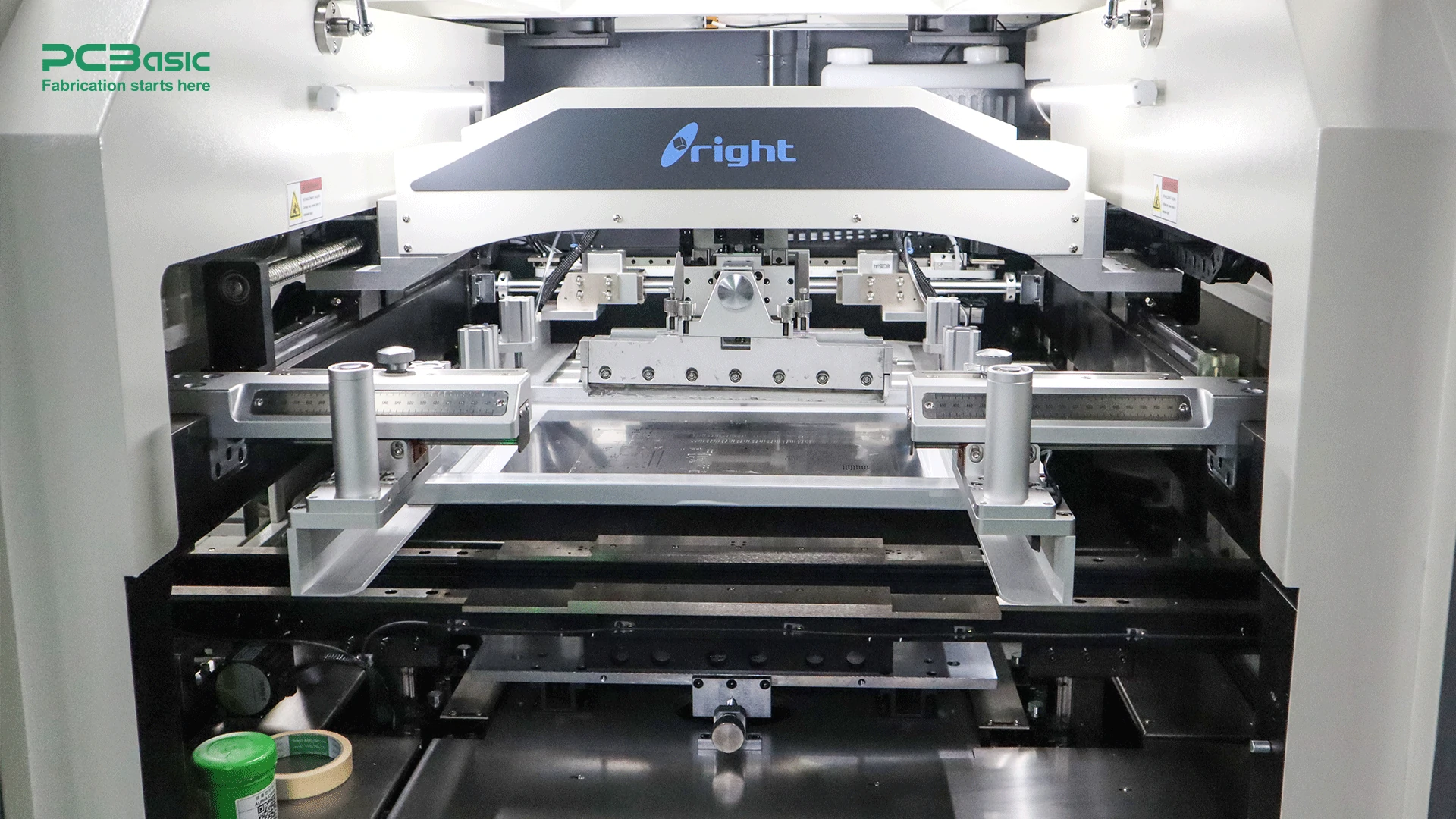

In addition to providing components, distributors often supply or source SMT equipment like:

This comprehensive support ensures seamless operations across SMT lines.

Leading SMD distributors offer tailored solutions for specific applications. Whether a manufacturer needs custom-designed SMDs for automotive components or optimized materials for high-speed SMT assembly, distributors ensure the right fit.

An efficient SMD distributor simplifies the procurement process, allowing manufacturers to focus on improving their SMT assembly processes.

Distributors provide the latest surface mount devices and SMT machines, helping manufacturers stay competitive in the fast-evolving electronics industry.

By maintaining relationships with multiple component manufacturers, distributors can negotiate better pricing, reducing costs for SMT PCB assembly.

Distributors often act as consultants, offering guidance on selecting the best SMT equipment and supplies for specific SMT production lines.

Selecting the right surface mount device distributor is crucial for ensuring smooth PCB SMT assembly. Consider the following factors:

The distributor should offer a wide range of SMDs, SMT supplies, and electronic components, catering to diverse needs across different SMT lines.

Ensure the distributor provides certified and reliable components that meet industry standards, particularly for critical applications like automotive components.

Look for distributors with robust inventory systems to prevent supply chain disruptions in SMT production lines.

The distributor should provide technical assistance, especially for SMT equipment setup and maintenance.

For manufacturers operating internationally, working with a distributor who has a global presence ensures consistent supply.

While SMD distributors play a critical role, the industry faces challenges such as:

The role of SMD distributors is set to grow with advancements in the electronics industry. Here are some trends to watch:

With the demand for smaller and more efficient electronic products, distributors will prioritize ultra-miniature SMDs and high-density SMT equipment.

Distributors will increasingly supply eco-friendly materials and energy-efficient SMT machines to support sustainable manufacturing.

As SMT production lines adopt more automation, distributors will offer advanced SMT supplies compatible with AI-driven SMT machines.

The rise of electric vehicles and autonomous driving will drive demand for specialized automotive components and surface mount devices.

Surface mount device distributors are the unsung heroes of the electronics industry, ensuring manufacturers have access to the SMDs, SMT machines, and SMT supplies needed for efficient SMT PCB assembly. Their role extends beyond component delivery to providing technical support, inventory management, and custom solutions for SMT production lines.

In a competitive market, choosing the right distributor is key to achieving success in PCB assembly and producing cutting-edge electronic products. With the growing demand for advanced technology, SMD distributors will continue to play a pivotal role in shaping the future of the electronics industry.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.