Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Get Prototype PCB Assembly Service from PCBasic

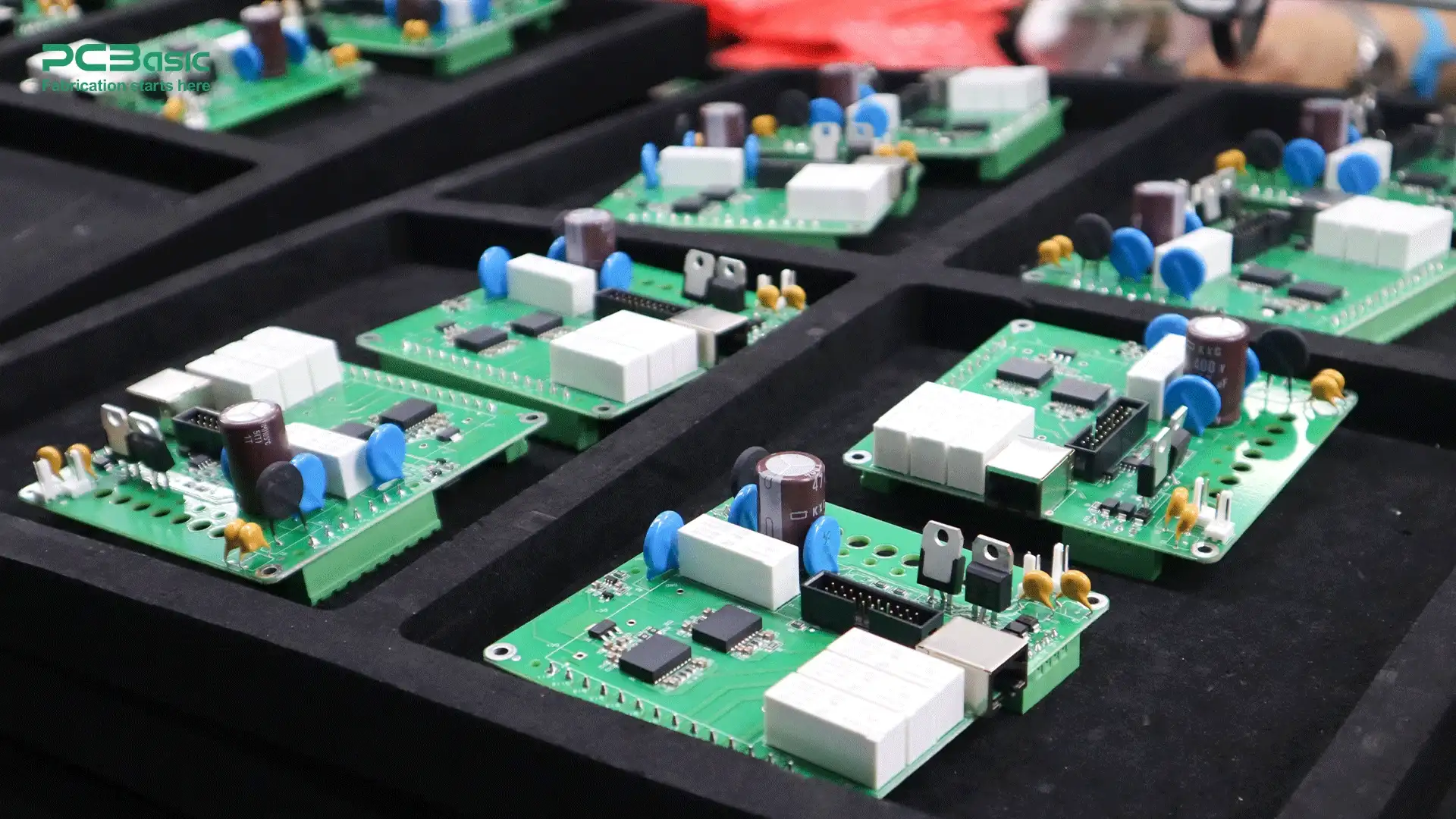

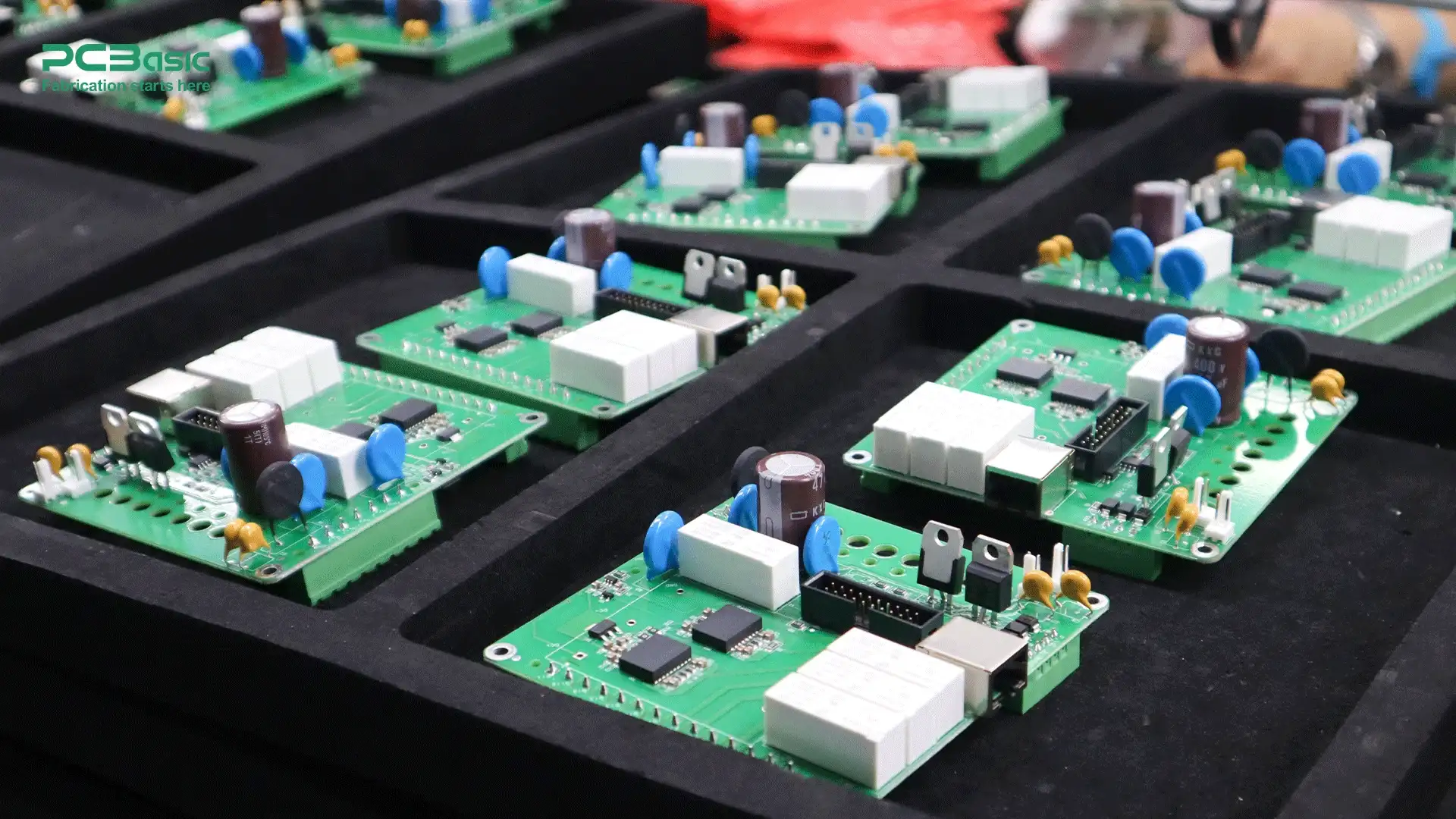

In the competitive world of electronics, the role of prototype printed circuit board (PCB) assembly cannot be overstated. It is a critical step in the development of new electronic devices, allowing engineers to test and refine their designs before committing to full-scale production. PCBasic, a prominent PCB manufacturer in China, offers extensive prototype PCB assembly services that cater to various industries, including automotive electronics, medical devices, and smart home applications.

Prototype PCB assembly involves creating an initial version of a printed circuit board to verify the design's feasibility and functionality. This process includes assembling electronic components onto the circuit board to create a working model that can be tested and refined. It is a critical step in the product development cycle, allowing designers to identify and rectify any design flaws before mass production.

Prototype PCB assembly is essential for design verification. By creating a prototype PCB, engineers can conduct functional testing to ensure that the circuit board performs as expected. This step is crucial for identifying potential issues early in the development process.

Investing in prototype PCB assembly can lead to significant cost savings. By identifying design flaws during the prototyping phase, electronic manufacturers can avoid costly rework during mass production. This cost-effective approach ensures that resources are used efficiently.

Quick turn PCB assembly services provided by companies like PCBasic enable rapid prototyping, which accelerates the development process. This allows products to reach the market faster, giving companies a competitive edge.

Prototype PCB assembly helps ensure that the final product meets all quality standards and specifications. Through rigorous testing and inspection, printed circuit board manufacturers can guarantee the reliability and performance of their products.

The first step in prototype PCB assembly is design preparation. Engineers create detailed schematic diagrams and layout plans using specialized software. These designs are then converted into Gerber files, which are used for manufacturing custom PCBs.

Component placement is a critical phase in circuit board assembly. Using automated pick-and-place machines, components are accurately positioned on the circuit board according to design specifications. This step is crucial for ensuring precise surface mount technology (SMT) application.

Soldering is an essential part of printed circuit board assembly. Techniques such as reflow soldering or wave soldering are used to secure components onto the board, ensuring reliable electrical connections.

Once assembled, the prototype undergoes rigorous inspection and testing. This includes manual inspections, automated optical inspections (AOI), and functional testing to verify its performance and identify any defects.

PCBasic stands out as a leading provider of prototype PCB assembly services due to its commitment to quality, speed, and innovation. Here are some reasons why you should consider PCBasic for your next project:

Contract manufacturers play a vital role in the electronics industry by providing specialized PCB assembly services. They offer expertise in custom circuit board design and manufacturing, allowing electronic manufacturers to focus on their core competencies. As a contract manufacturer, PCBasic provides turnkey PCB assembly solutions that include everything from design consultation to final product delivery.

Prototype PCB assembly is an indispensable part of modern electronics manufacturing. It enables designers to validate their concepts and ensure product quality before entering mass production. PCBasic offers reliable and efficient prototype PCB assembly services that cater to various industries' needs. With its focus on speed, quality, and technological innovation, PCBasic is well-positioned to support electronic manufacturers in bringing their ideas to life efficiently and effectively. Whether you need custom circuit boards or turnkey PCB assembly solutions, PCBasic provides comprehensive services that meet your requirements with precision and reliability.

By choosing PCBasic as your partner for prototype PCB fabrication service, you gain access to a wealth of expertise in circuit board assembly services. As a leading China PCB manufacturer with extensive experience in pcb manufacturing and assembly, PCBasic ensures that your project is handled with the utmost care and professionalism.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.