Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Main PCB Assembly: How to Do It?

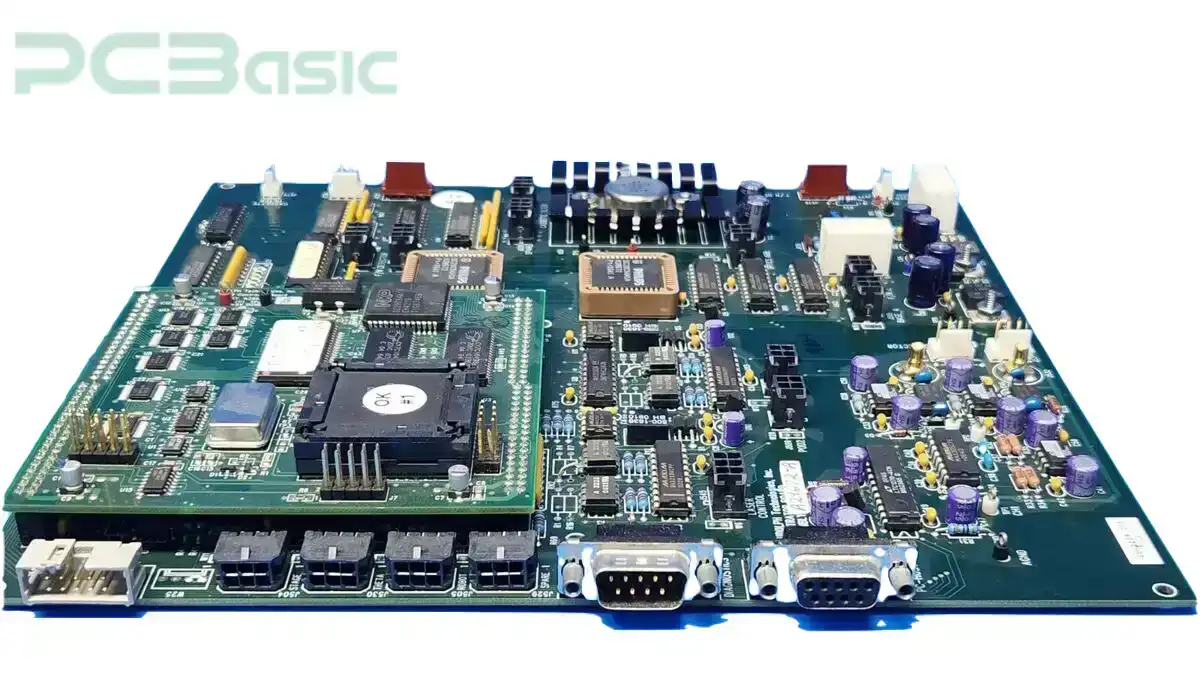

In many complex devices, there is not only one circuit board, which is generally composed of a main PCB and general PCBs, each responsible for different functions. So, what is the main PCB assembly? How is it different from general PCBA? How can you find affordable and reliable main PCB assembly suppliers from China?

In this blog, we will delve into the main PCBA meaning, compare the differences between PCB vs PCBA, and detail the process of main PCB assembly. Whether you are a professional in PCBA manufacturing or someone who wants to know "what is a PCB assembly?", this guide will provide you with practical information.

In almost all electronic devices, the printed circuit board (PCB) plays a vital role. It is the core of modern electronic devices. On the one hand, it provides a stable physical platform for electronic components. Through precise design and manufacture, PCBs can be fixed resistors, capacitors, chips and other components. On the other hand, PCBs can do the electrical connection between electronic components through conductive traces on their surface and inside, effectively transmitting signals and electrical energy, while optimizing signal integrity through reasonable layout and reducing electromagnetic interference.

Just like the human brain, the main PCBs, as the core of the electronic device, connect all the key components of the device and is the center of electrical signal transmission, power distribution and component integration.

As the core part of the electronic device, the main PCB is responsible for integrating and connecting key hardware components, such as the central processing unit (CPU), memory, power management units, and various input and output modules. In addition, it can distribute external power input to the various components of the device, and regulate current and voltage through the integrated voltage regulator module (VRM) or power management unit (PMU) to ensure stable operation of the device under different workloads.

In general, the main PCB board plays a crucial role in the overall function of the device. It hosts the microcontroller, connectors, and other PCBA components necessary to enable communication and power flow between subsystems.

Understanding the main PCBA meaning, especially in the context of a main PCB board, is an important step in optimizing design, simplifying manufacturing, and ensuring equipment reliability.

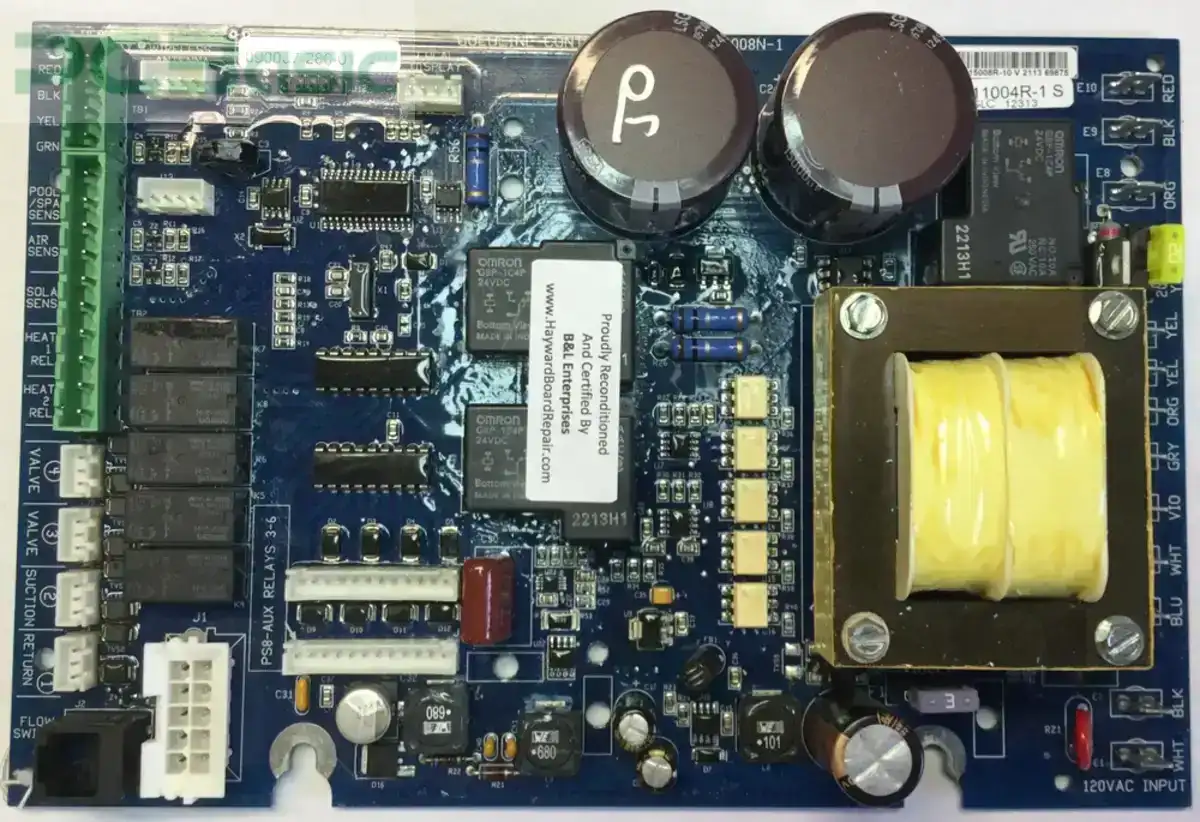

Unlike the main PCB, the design of the general PCB is much simpler. It does not have comprehensive functions like the main PCB, but provides specific functional support for electronic equipment, and is widely used in the auxiliary function module of electronic equipment. General PCBs and the main PCBs work together to build the complete functional system of the device.

Let’s explore their detailed differences in this table:

|

Characteristic |

Main PCB (Main Circuit Board) |

General PCB (General Circuit Board) |

||

|

|

Functional Complexity |

Highly complex, integrates multiple core functions |

Relatively simple, typically implements a single function |

|

|

|

System Role |

Core of the system, responsible for overall control and management |

Auxiliary module, supports specific tasks or functions |

|

|

|

Design Structure |

Multi-layer design, focuses on high-speed signals and high-density integration |

Single-layer or double-layer design, emphasizes simplicity and reliability |

|

|

|

Component Type |

Includes high-performance chipsets and interface modules |

Contains basic electronic components (like resistors and capacitors) |

|

|

|

Application Scenarios |

Complex devices like smartphones, computers, and home appliances |

Simple devices like power modules, display drivers, and sensor interfaces |

|

Although in many cases, people confuse the two terms: main PCB and motherboard, the functions and application scenarios are different. Main PCB refers to the main circuit board in a variety of complex electronic devices, which is responsible for integrating and managing the core functions of the device, it is a broader concept. However, motherboard is a specific type of main PCB, mainly used in devices such as computers and servers. The two differ in function positioning and application scenarios, but both play key roles in device operation.

The main PCB assembly refers to the process of installing all the necessary electronic components onto the main PCB, making it a functional core circuit board. This process includes not only the production of the main circuit board itself, but also the soldering, installation and functional testing of the components to ensure that the circuit board can fulfill the core functions of the device.

In the process of the main PCB assembly, the selection and integration of components has a significant impact on the function of the device, and each component plays an indispensable role in the normal operation of the device. In the a main PCB assembly, the following components are usually included:

1. Integrated Circuits (ICs) :

Integrated circuits, which integrate a large number of electronic components, such as transistors, resistors, capacitors., into a small semiconductor material, is the most important functional component in the main PCB, directly affecting the computing power and intelligence level of the device.

2. Passive components:

Passive components, including resistors, capacitors and inductors, are those electronic components that do not require external power drivers and do not have signal amplification functions in the circuit, they play a fundamental role in the signal processing and energy management of the circuit.

3. Connectors:

Connectors are components used to achieve electrical connections between the main PCBS and other subsystems. They are an important part of the design of electronic devices to ensure reliable transmission of signals and power between different modules or subsystems.

Main PCB assembly is the process of converting a bare PCB into a functional circuit board, involving multiple precise steps.

Design and Preparation Stage

This is the first step to make sure that you have the design files and materials ready. Engineers can utilize EDA tools (like Altium Designer or KiCad) to finish PCB design and then export the required files such as Gerber and drill files. A Bill of Materials (BOM) is generated with the footprint, specifications, and supplier of each component. After all materials are prepared, the main PCB comes to assembly.

Solder Paste Printing

The first step of the Surface Mount Technology (SMT) process is solder paste printing, I applying solder paste onto the PCB’s pads using a stencil. A stencil with holes corresponding exactly to the pad layout is clamped to the PCB, and a squeegee then applies solder paste to the stencil and fills the hole.

Component Placement (Pick and Place)

Component placement is one of the most important stages which need extreme precision and speed. Pick-and-place machines utilize predetermined coordinates to pick up Surface Mount Devices (SMDs) from their corresponding feeders and then accurately place them down onto pads with this solder-paste material applied.

Reflow Soldering

This is about melting the solder paste to solidify the connections between the SMDs and the PCB. The PCB is passed through a reflow oven with a well-defined thermal profile, generally consisting of four phases: preheat phase, soak phase, reflow phase, and cooling phase. To avoid thermal shock, preheating gradually heats the PCB.

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) systems inspect solder joint and component placement quality after reflow soldering. High-resolution cameras take images of the PCB, and sophisticated software compares them to a baseline to find defects (such as missing solder, solder bridges, misaligned components, and other issues).

Through-Hole Component Assembly (THT Soldering)

The assembly of components that need to be through-hole mounted like connectors, large capacitors or transformers differs from the process. Components arrive at the facility, often they are automated and wired manually and attached to pre-drilled holes on the PCB. A very popular soldering method is wave soldering, where the PCB is passed over a wave of molten solder to make the attachments rot through-hole leads to the board. Letting more sensitive or special components to be soldered by skilled technicians themselves, using a manual soldering tool.

Testing Stage

Testing is a vital step to verify the PCB's electrical and functional integrity. There are In-Circuit Testing (ICT), Functional testing (FT) and Stress or Burn-In Testing.

Clean and Inspect for Quality

To remove solder flux residues and contaminants, PCBs undergo cleaning using specialized solvents or ultrasonic cleaners. Cleanliness is critical for high-density PCBs, as residues can cause electrical leakage or corrosion. After cleaning, visual inspections are conducted to check for physical damage, proper silkscreen markings, and overall product aesthetics. Final quality assurance checks ensure the PCBs meet industry standards, such as IPC-A-610, and the specific requirements outlined by the customer.

When looking for main PCB assembly suppliers in China, PCBasic stands out as a trusted partner. Here’s why PCBasic is the perfect choice to meet your needs for main PCB assembly quotes:

Comprehensive One-Stop Services for Main PCB Assembly

PCBasic is a one-stop solution for the main PCB assembly in China. Its solution covers everything from PCB design, fabrication, material sourcing, to assembly, which can also reduce your expenses by improving efficiency in your processes. If you are looking for the best main PCB assembly suppliers, your perfect choice is to contact PCBasic.

Industry Expertise and Experience

PCBasic has more than 15 years of PCB & SMT experience; It is a top China main PCB assembly supplier. Each profile, from small prototype orders to large-scale productions is fabricated with precision by its team of seasoned engineers and designers.

Advanced Technology for Superior Quality

Additionally, PCBasic utilizes advanced CRM/MES/ERP/IoT management systems to achieve industrial intelligence. For those seeking main PCB assembly quotes, it can provide high-quality products backed by state-of-the-art inspection systems like SMT fault detection and ESD electrostatic protection.

Certified Quality Assurance

PCBasic has earned ISO9001, IATF16949, and ISO13485 certifications, making us a trusted name among main PCB assembly suppliers in China. We prioritize quality, ensuring that every PCB assembly meets international standards.

Exceptional Customer Support

For businesses seeking main PCB assembly suppliers, PCBasic provides 24/7 customer support. We offer fast response times, ensuring your inquiries about main PCB assembly quotes are addressed promptly and efficiently.

The main PCB assembly is one of the most important steps in the circuit board assembly process, which produces the main circuit board that integrates and manages essential functions of electronic devices. Compared to general PCBs, the main PCBs features greater functionality and complexity and serve as the central hub for communication and power flow.

If you are looking for leading main PCB assembly suppliers or need competitive main PCB assembly quotes from China, then PCBasic China stands out with its versatile one-stop services, advanced technology, certified quality standards, and high-grade customer support. With over 15 years of industry expertise, PCBasic delivers high-quality solutions tailored to your needs.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.