Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCB Cable Assembly | A Comprehensive Guide

Cables are the basic integral/component part of each and every electrical system because they include one or more electrical conductors (here, usually the electrical conductor will be either copper or aluminum) and insulating material to facilitate the passing of power or signal to other devices. Various cables include power cables, data cables, and control cables, and every kind of cable is designed for a certain application occasion. Cable assembly refers to the procedure of creating custom cables to unique specifications for use in a myriad of components and/or devices that could be utilized in an industrial or consumer environment. PCB cable assemblies offer dependable connectivity to the rest of the system and are essential in most electronic products today. This article introduces you to different types of PCB cable components, their benefits, and how they help to simplify and enhance the performance of electronic devices.

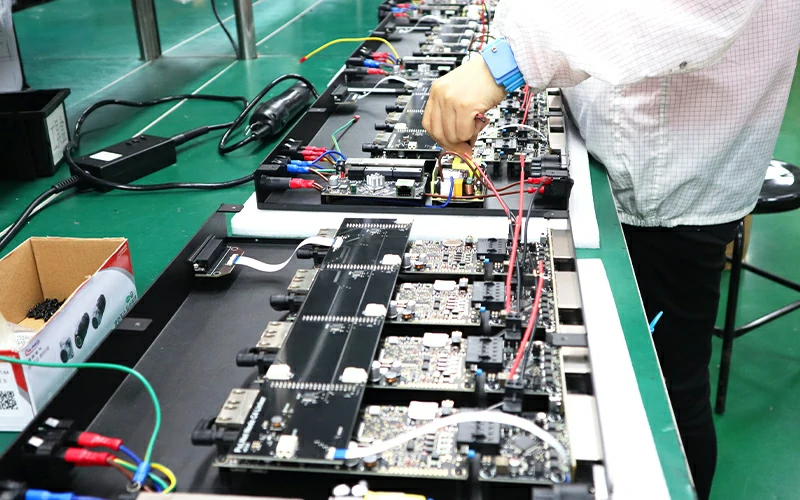

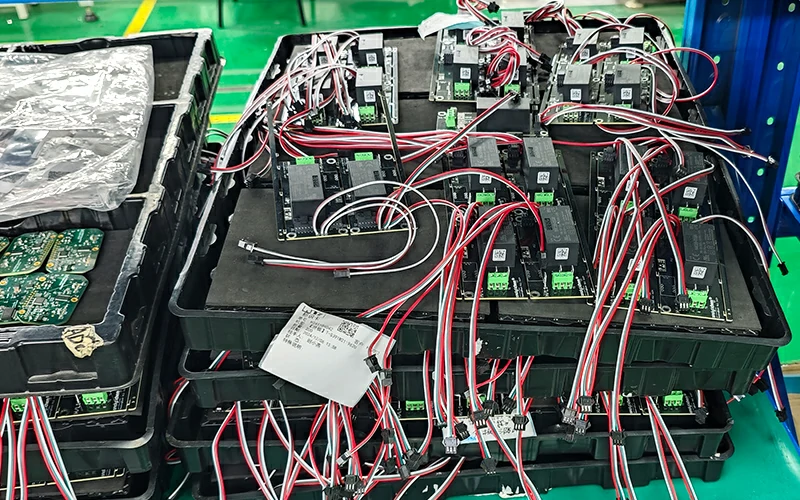

PCB Cable Assembly is wherein the cable is connected to the PCB (printed circuit board) and typically involves many techniques including termination, welding, and wiring of the cable to transmit electricity and power from the cable to the PCB at a specific location. This process is commonly used to connect various electronic components such as sensors, buttons, displays, connectors, etc., ensuring reliable communication and power supply between the circuit board and external devices, playing a crucial role in modern electronics.

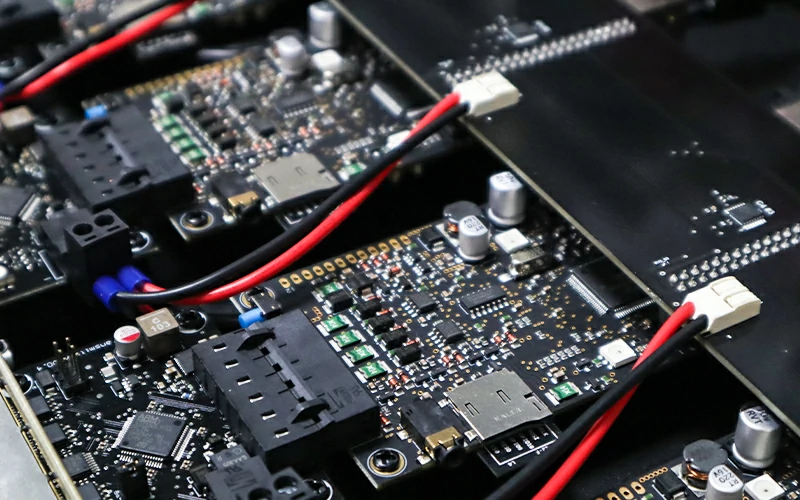

1. Wire

The main function of the wire in the PCB cable assembly is to carry electrical signals or power. When selecting a wire, consider the current carrying capacity of the wire, flexibility (in a flexible PCB cable assembly, the wire must be flexible enough so that it will not be damaged during repeated bending) and durability. Common wire materials include copper or silver-plated copper.

2. Outer Sheath

The outer sheath/cladding is an important protective layer for cables and is usually made of durable materials: PVC, TPE, PE PUR, etc. The specific material choice depends on the environmental and performance requirements. It protects the internal components of the cable from dust, moisture, and physical damage; it prevents electrical short circuits; It provides multiple functions such as mechanical strength and resistance to electromagnetic interference, ensuring that the cable can operate stably in complex environments. PCBasic typically offers a variety of sheathing materials to meet different standards and regulations.

3. Insulating material

Insulating material is a key component in the PCB cable assembly, which works to prevent short from happening by separating the wires conductors. The commonly used insulating materials include PVC, PE, and PTFE in China PCB cable assembly products, and its selection depends on voltage rating, working temperature, and exposure to fluid in the environment.

4. EMI shielding (Electromagnetic Interference)

Generally speaking, EMI shielding is critical for PCB cable assemblies as they are protecting sensitive components of the PCB and avoiding signal degradation and system failures, especially in high-frequency applications which are more susceptible to EMI from external sources.

5. Connector/terminals

Connectors establish a physical connection between the cable and PCB or other peripheral device. There are several types of connectors, each serving a specific function. The most commonly used connectors are header connectors, coaxial connectors, and pin connector headers. PCBasic will provide the necessary connectors to ensure compatibility according to the design and operational requirements.

|

Types |

Description |

Applications |

Key Features |

|

AV Cable |

Used for transmitting audio and video signals in multimedia devices. |

Common in TVs, home theater systems, gaming consoles, and consumer electronics. |

Requires high shielding and low resistance to maintain signal integrity. |

|

Flat Ribbon Cable |

Used in applications with limited space and multiple signal paths connecting PCBs to devices. |

Found in computer systems, printers, and internal electronic device connections. |

Flexible, compact, and space-optimized. |

|

Molded Cable |

Features a plastic outer casing to securely hold connectors and protect internal wires from physical damage. |

Used in harsh environments and industrial applications where durability and pressure resistance are needed. |

Provides high durability and protection against physical damage. |

|

EMI Shielded Cable |

Designed to protect systems from electromagnetic interference (EMI). |

Used in electronic applications where signal integrity is critical, such as medical devices, communication equipment, and high-frequency power cables. |

The shielding layer prevents EMI from affecting system performance. |

PCB cable components can not only provide high quality assurance of signal transmission, but also have many other advantages, such as compact design, durability, anti-interference ability, etc., playing a key role in various fields.

1. Simplify PCB assembly

An important advantage of using PCB cable assemblies is that the overall PCB assembly process can be simplified, and the PCBA space can be optimized (for example, the design of flat cable is very flexible and compact and can provide multiple signal path connections in a limited space). Pre-assembled cables can help eliminate the need for individual component welding, which can reduce installation difficulty, maintenance time, and the probability of errors during assembly for some complex electronic products.

2. Reduce electromagnetic interference

EMI shielding cables in PCB cable assembly provide an external shielding layer that can effectively prevent electromagnetic interference from affecting the normal operation of electronic devices, which is especially important for devices that are critical to signal integrity, such as medical devices, communications equipment, and high-frequency power systems.

3. Reduce costs

PCB cable assemblies can often be automated, and multiple cable paths can be handled simultaneously in a single production, which can effectively reduce costs. (Because wholesale PCB cable assemblies reduce the need to purchase components separately and manage multiple suppliers, making the entire assembly process more efficient.) And by choosing a reliable PCB cable assembly supplier, such as PCBasic, you can also save a lot of money. Because PCBasic will help you optimize the production process to provide you with the most suitable, best-quality PCB cable assembly solution, thereby saving a lot of costs.

4. Improve product performance

PCB cable assembly can improve the overall product performance, improve the adaptability of PCB, signal transmission integrity, can adapt to a variety of application needs. PCB cable assemblies made of high-quality materials also enhance the safety and long-term durability of PCBA.

|

Step |

Description |

|

1. Material Selection |

Choose high-quality conductors, insulation materials, and connectors that meet industry standards and customer specifications. |

|

2. Cable Stripping and Terminal Processing |

Stripping the cable and attaching terminals or connectors. This process requires precision to ensure good contact and prevent damage to the wires. |

|

3. Soldering and Assembly |

Use soldering techniques to connect the cable to the PCB, ensuring a secure electrical and mechanical connection. |

|

4. Testing and Quality Control |

After assembly, extensive tests are conducted, including continuity tests, insulation resistance tests, and mechanical stress tests, to ensure the cables meet electrical and mechanical specifications. |

|

5. Final Product |

Deliver high-quality, reliable PCB cable assemblies that are widely used in industries such as automotive, medical, and telecommunications. |

|

Service |

Description |

|

Customized Cable Lengths, Wire Types, and Connectors |

Customize cable lengths, wire types, and connectors to match specific design requirements. |

|

Integration of Additional Components |

Integrate additional components, such as resistors, capacitors, and protection diodes, to enhance the functionality of the cable assemblies. |

|

Bulk Order Services |

Offer bulk orders of PCB cable assemblies to reduce costs and optimize supply chain management for large projects. |

|

Components Designed for Sensitive Applications |

Provide power cable PCB assemblies and components specifically designed for sensitive applications such as medical instruments, automotive electronics, and industrial automation. |

PCB cable assemblies are pretty common in lots of industries, facilitating electrical connections for power, data transmission, and signal integrity in several different kinds of applications. PCB cable assemblies play a vital role in maintaining consistent power delivery and data transmission in medical devices, such as diagnostic equipment, surgical instruments, and monitoring systems. Especially in this field, EMI shielding cables are highly important as they help transmit signals without any disturbance, which is crucial to the performance of medical equipment.

1. Networking and Telecom Systems

PCB cable assemblies are key to connecting devices such as routers, switches, and servers, enabling high-speed data transmission. Power cable assemblies help ensure the stable operation of network hardware. In China, PCB cable manufacturers offer customized solutions to meet the high-performance needs of data centers and communication infrastructures.

2. Automotive Industry

In the automotive industry, electronic systems rely heavily on PCB cable assemblies for power, control signals, and data transmission. These assemblies are used in critical automotive systems, including ignition, airbag control, and engine management. Additionally, flexible PCB cable assemblies are used in moving parts like door systems and seats, ensuring the safe and reliable operation of automotive electronics in harsh conditions.

3. Industrial Control and Automation

PCB cable assemblies connect sensors, controllers, actuators, and other devices, enabling the transmission of power and signals in environments affected by vibration, temperature fluctuations, and other harsh conditions. Power cable assemblies are used in machinery to provide stable power, while EMI shielding cables help prevent interference in control systems, ensuring higher system reliability.

4. Consumer Electronics

The consumer electronics market also extensively uses PCB cable assemblies in products such as smartphones, tablets, televisions, and smart home devices. These assemblies ensure the proper transmission of power, data, and audio/video signals, contributing to the proper functionality and performance of the devices. Components like connectors and data transmission cables are commonly used in these applications.

5. Aerospace

In aerospace, PCB cable assemblies play a critical role in connecting spacecraft, satellites, and aircraft systems like sensors, control systems, and power systems. Due to the extreme environmental conditions in aerospace applications, these components must be highly reliable and resistant to interference. High-temperature cable assemblies and EMI shielding cables are often used to meet the demanding conditions of this industry.

6. Wearable Devices

Wearable devices, such as smartwatches and health monitoring devices, require compact, high-performance PCB cable assemblies that can deliver power and facilitate data transmission within a small form factor. Miniature power cable assemblies, data transmission cables, and flexible PCB cable assemblies are typically used to meet the space constraints and performance requirements of these devices.

7. Robotics

In the robotics field, PCB cable assemblies are used to transmit power and control signals to moving parts and sensors of robots. Flexible PCB cable assemblies are commonly employed in mobile robots to allow for continuous movement while ensuring precise control and signal transmission.

These diverse applications demonstrate the versatility of PCB cable assemblies and their integral role in powering and connecting a wide range of devices across multiple industries.

PCB cable assemblies link and connect different electronic devices or components together, supplying power, communication, or control signals in many industries. The adaptability of these components makes them applicable in various fields, such as medical devices, telecommunications, automotive systems, and industrial automation, including flexible PCB cable assemblies, power cable PCB assemblies, etc. When companies partner with a reliable PCB cable assembly manufacturer or supplier, they are able to gain reliability, efficiency, and cost efficiency in their products. We at PCBasic devote ourselves to high-quality customized solutions that match the exact needs of our customers.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.