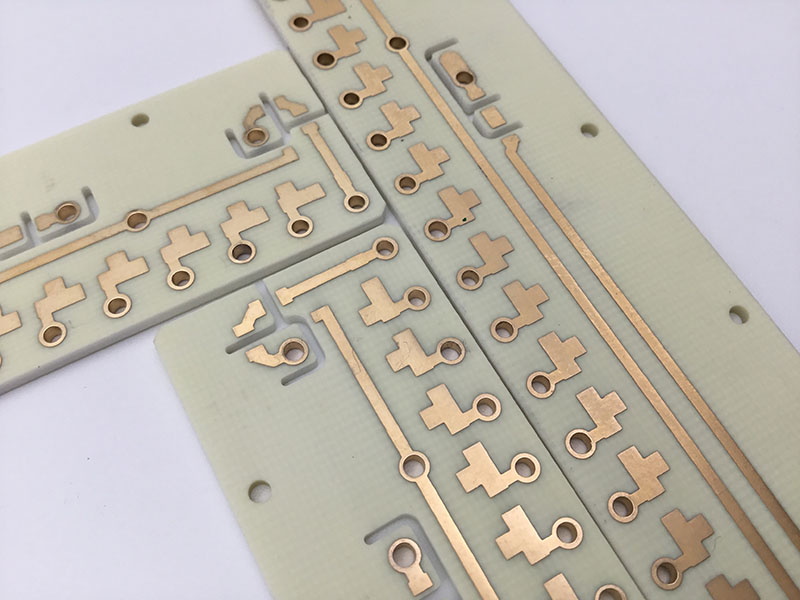

Multilayer PCB Definition

Generally, there are single-sided, double-sided and multilayer PCB board. For some

simple electrical appliances, such as radios, a single-sided PCB is sufficient. However,

with the development of the times, for multi-functional and small-volume electronic

products, single-sided and double-sided PCB can not fully meet the requirements, but

multilayer PCB board must be used. Multilayer PCB board has many advantages, such as:

high assembly density and small volume; The connection between electronic components is

shortened, the signal transmission speed is fast, and the wiring is convenient; Good

shielding effect, etc.

There is no limit to the number of layers of multilayer PCB board. At present, there are

more than 100 layers of multilayer PCB board, commonly 4L and 6L PCB boards. Then,

multilayer PCB board compares with single-sided PCB and double-sided PCB, which layers

are composed of? What are their meanings and uses? Let's have a look together.

Signal Layer

The signal layer is divided into the top layer, the middle layer and the bottom layer,

and is mainly used for placing various components or for wiring and welding.

Internal Plane Layer

The internal plane layer, also known as the internal power layer, is dedicated to the

layout of power lines and ground lines. This type of layer is only used for multilayer

PCB board. We call it double-layer, 4L and 6L boards, generally referring to the number

of signal layers and internal power/ground layers.

Mechanical Layer

Mechanical layer defines the appearance of the whole multilayer PCB board. In fact, when

we talk about mechanical layer, we mean the appearance structure of the whole multilayer

PCB board. Mechanical layer is generally used to place indicative information about

board making and assembly methods, such as physical dimension line of circuit board,

data, via information, etc. This information varies according to the requirements of

design companies or PCB manufacturers. In addition, the mechanical layer can be attached

to other layers to output the display together.

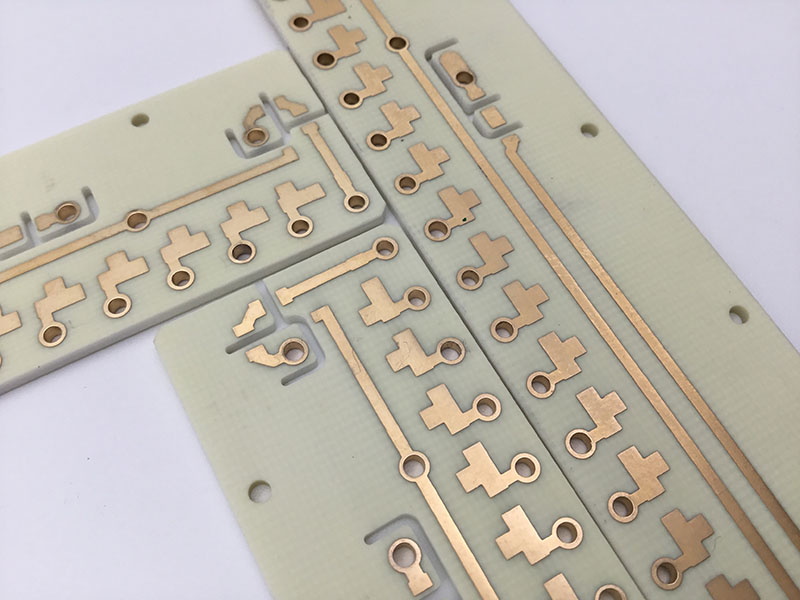

Solder Mask Layer

Refers to the part of the multilayer PCB board to be painted with green soldermask oil.

Actually, the soldermask layer uses negative output, so after the shape of the

soldermask layer is mapped onto the board, the soldermask is not painted with green oil,

but the copper is exposed. Usually, in order to increase the thickness of copper foil,

the soldermask is removed green oil, and then tin is added to increase the thickness of

copper wire.

Paste Mask Layer

Its function is similar to that of soldermask layer, except that it corresponds to the

pad of surface-mounted component during machine welding. Maybe at this point, everyone

is still confused about the concepts of soldermask layer and paste mask layer. In fact,

to sum up:

Role:

① Soldermask layer is mainly used to prevent PCB copper foil from being directly exposed

to the air and play a protective role.

② Paste mask layer is used to make stencil mesh, and the stencil mesh can accurately put

solder paste on the SMD pad to be soldered.

Difference:

① Soldermask layer means to open a window on the whole piece of soldermask green oil in

order to allow welding.

② By default, all areas without solder mask should be coated with green oil.

③ Solder flux layer is used for SMD packaging.

Keep out Layer

Used to define the area where components and wiring can be effectively placed on the

circuit board. Draw a closed area on this floor as the effective area for wiring, and it

is impossible to automatically lay out and wire outside this area.

Silkscreen Layer

Silkscreen layer is mainly used to place printed information, such as outline and

marking of components, various annotation silkscreens, etc. Generally, all kinds of

marked silkscreens are in the top silkscreen layer, and the bottom silkscreen layer can

be closed.

Multi-Layer

The upper pad of the circuit board and the penetrating via hole need to penetrate the

whole multilayer PCB board and establish electrical connection with different conductive

pattern layers, so the system specially sets up an abstract multi-layer. Generally, the

pads and vias should be arranged on multi-layer, and if this layer is closed, the pads

and vias cannot be displayed.

Drill Layer

The drilling layer provides drilling information in the circuit board manufacturing

process (for example, pads and vias need to be drilled).

System

The working layer is used to display the information of violation of design rules.

Multilayer PCB design

1. Determination of board shape, size and number of layers Any multilayer PCB board has the problem of assembling with other structural parts.

Therefore, the shape and size of multilayer PCB board must be based on the structure of

the whole product. However, from the perspective of production technology, it should be

as simple as possible, generally rectangular in length-width ratio, so as to facilitate

assembly, improve production efficiency and reduce labor costs.

The number of layers must be determined according to the requirements of circuit

performance, board size and circuit density. For multilayer PCB board, 4L boards and 6L

boards are most widely used. Take 4L boards as an example, that is, two conductor layers

(component surface and soldering surface), one power layer and one ground layer.

The layers of the multilayer PCB board should be symmetrical, and it is best to have

even copper layers, i.e. four, six, eight layers, etc. Because of asymmetric lamination,

the board surface is prone to warping, especially for surface-mounted multilayer PCB

board, which should be paid more attention to.

2. Location and orientation of components The location and placement direction of components should first be considered from the

aspect of circuit principle to cater to the trend of circuit. The rationality of the

placement will directly affect the performance of the multilayer PCB board, especially

the high-frequency analog circuit, which obviously requires more stringent device

location and placement.

Reasonable placement of components, in a sense, indicates the success of the multilayer

PCB design. Therefore, when setting out the layout of multilayer PCB board and deciding

the overall layout, we should make a detailed analysis of the circuit principle, first

determine the location of special components (such as large-scale IC, high-power

transistor, signal source, etc.), and then arrange other components to avoid possible

interference factors.

On the other hand, we should consider the overall structure of the multilayer PCB board

to avoid uneven arrangement and disorder of components. This not only affects the beauty

of multilayer PCB board, but also brings a lot of inconvenience to assembly and

maintenance.

3. Requirements of wire layout and wiring area In general, the wiring of multilayer PCB board is carried out according to circuit

functions. When wiring on the outer layer, it is required to have more wiring on the

welding surface and less wiring on the component surface, which is conducive to the

maintenance and troubleshooting of multilayer PCB board.

Thin, dense wires and signal lines susceptible to interference are usually arranged in

the inner layer. A large area of copper foil should be evenly distributed on the inner

and outer layers, which will help to reduce the warpage of the board and obtain a more

uniform coating on the surface during electroplating.

To prevent short circuit between layers caused by shape processing and printed wires and

mechanical processing, the distance between conductive patterns of inner and outer

wiring areas and the board edge should be greater than 50mil.

4. wire direction and line width requirements Multilayer PCB board wiring should separate the power layer, ground layer and signal

layer to reduce the interference between power, ground and signal.

The lines of two adjacent multilayer boards should be perpendicular to each other or

inclined or curved as far as possible, instead of parallel lines, so as to reduce the

interlayer coupling and interference of the substrate. And the wires should be as short

as possible, especially for small signal circuits. The shorter the wires, the smaller

the resistance and the smaller the interference.

The signal lines on the same floor should avoid sharp corners when changing direction.

The width of the wire should be determined according to the current and impedance

requirements of the circuit. The power input line should be larger and the signal line

should be relatively smaller.

For general digital boards, the line width of power input line can be 50 ~ 80 mil, and

the line width of signal line can be 6 ~ 10 mil.

When wiring, it should also be noted that the width of lines should be consistent as far

as possible, so as to avoid sudden thickening and thinning of wires, which is conducive

to impedance matching.

5. Requirements of drilling hole size and pad The hole size of components on multilayer PCB board is related to the pin size of

selected components. If the drilling hole is too small, it will affect the installation

and soldering of the device; The drilling hole is too big, and the welding spot is not

full enough during welding. Generally speaking, the calculation method of component hole

diameter and pad size is:

※Diameter of component hole = diameter of component pin (or diagonal line)+(10 ~ 30 mil)

※Element pad diameter ≥ element hole diameter +18mil

As for the via hole diameter, it is mainly determined by the thickness of the finished

board. For high-density multilayer boards, it should generally be controlled in the

range of board thickness: hole diameter ≤ 5: 1.

The calculation method of VIAPAD is: via pad diameter ≥ via diameter +12mil.

6. Requirements of internal plane layer, ground layer partition For multilayer PCB board, there is at least one power layer and one ground layer.

Because all the voltages on the multilayer PCB board are connected to the same power

layer, the power layer must be partitioned and isolated. Generally, the size of the

partition line should be 20 ~ 80 mil. The higher the voltage, the thicker the partition

line.

In order to increase the reliability and reduce the virtual welding caused by large-area

metal heat absorption in the welding process.

The aperture of isolation pad ≥ drilling aperture +20mil

7. Requirements for safe spacing The setting of safety distance should meet the requirements of electrical safety.

Generally speaking, the minimum spacing of outer conductor shall not be less than 4mil,

and the minimum spacing of inner conductor shall not be less than 4mil. Under the

condition that the wiring can be arranged, the spacing should be as large as possible,

so as to improve the finished product rate and reduce the hidden trouble of finished

board failure.

8. Improve the anti-interference ability of the whole board. Multilayer PCB design must also pay attention to the anti-interference ability of the

whole board. The general methods are:

Add filter capacitor near the power supply and ground of each IC, the capacity is

generally 473 or 104.

For sensitive signals on multilayer PCB, accompanying shielding wires shall be added

separately, and wiring near signal sources shall be as little as possible.

Choose a reasonable grounding point.