Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What is SMD? | Surface Mount Device

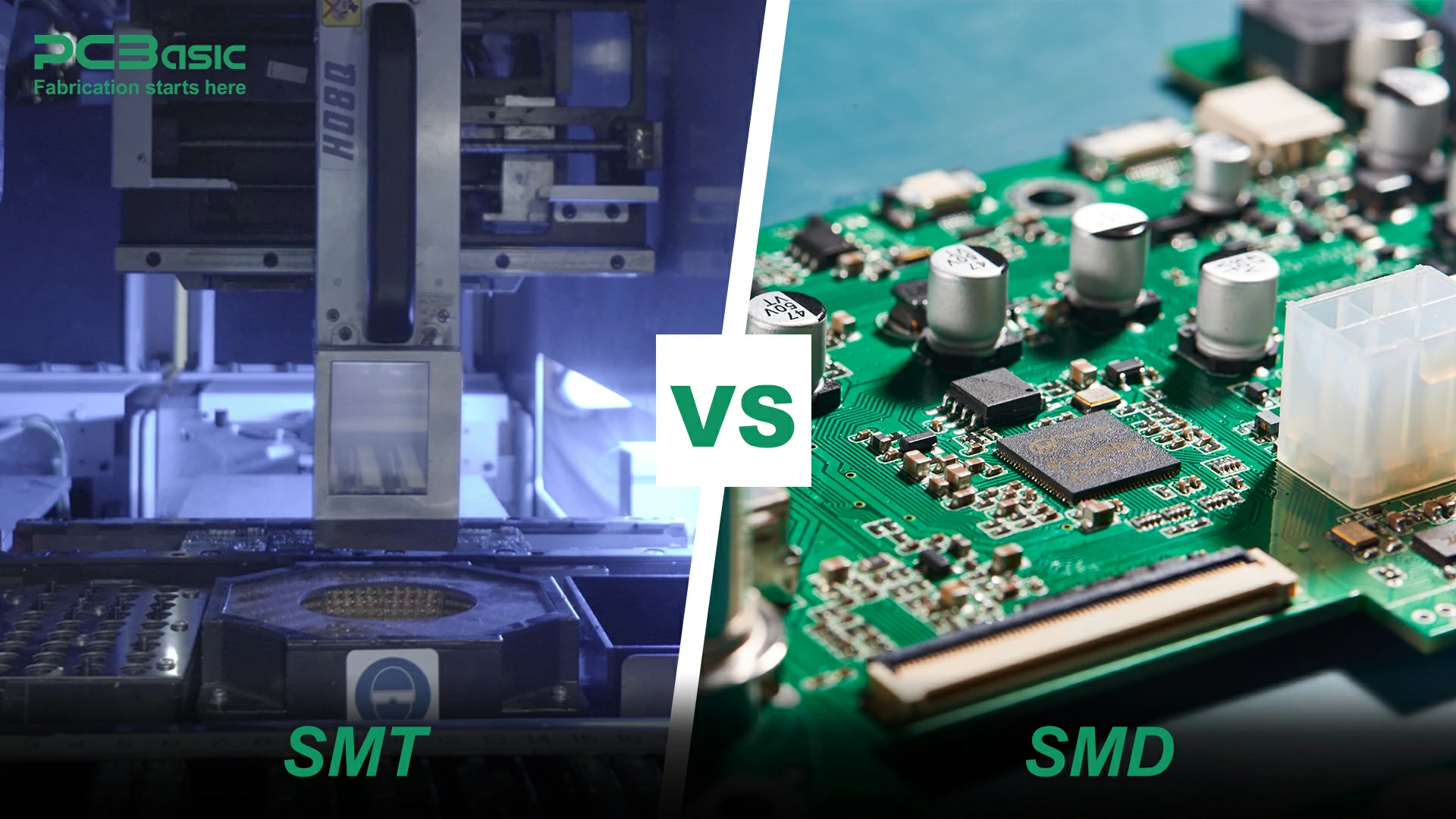

In the world of modern electronic devices, terms like SMD and SMT are frequently used, especially in PCB assembly and circuit board design. But what does SMD mean, and why is it crucial in electronic circuits? This blog dives into the SMD meaning, its role in SMT manufacturing, and the unique characteristics that make it indispensable in today’s technology.

SMD stands for Surface Mount Device, a type of electronic component designed to be mounted directly onto the surface of a circuit board. Unlike traditional components with long leads inserted into holes, SMD components save space and improve efficiency in electronic circuits.

In PCB assembly, SMD components are attached using solder paste and a process called SMT assembly (Surface Mount Technology). This process is a cornerstone of SMT manufacturing, allowing the production of smaller, more efficient electronic devices such as smartphones, power supplies, and IoT gadgets.

1. SMD Capacitors: Store and regulate electrical energy in electronic circuits.

2. Integrated Circuits (ICs): Power the brains of most modern electronic devices.

3. Resistors: Control current flow in circuit boards.

4. Transistors: Amplify and switch signals in electronic circuits.

These SMD components are central to the functionality of various electronic devices, from household appliances to industrial machinery.

The transition from traditional wave soldering to SMT assembly revolutionized the production of electronic devices. By using solder paste and advanced machinery, SMT manufacturing enables precise placement of SMD components onto circuit boards, making devices smaller, faster, and more reliable.

Unlike through-hole components that require wave soldering, SMT components like SMD capacitors and integrated circuits are soldered directly onto the board’s surface. This direct placement offers several advantages:

Understanding what SMD means and its role in SMT manufacturing is vital for anyone working with circuit boards and electronic devices. The adoption of surface mount devices and the evolution of SMT assembly have paved the way for more efficient and compact electronic circuits.

Whether you're designing a PCB or assembling SMD components, knowing their unique characteristics will help you create high-performance electronic devices.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.