Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > A Leading PCBA Contract Manufacturer in China | PCBasic

Many enterprises encounter challenges when working with PCB assembly manufacturers on mass production projects. For such enterprises that need to outsource PCB assembly, the stability of the PCBA contract manufacturer is of great importance. Choosing the right reliable contract manufacturer can help the enterprise avoid many detours in terms of quality, cost and delivery time.

PCBasic is a mature contract manufacturing service provider for PCBA in China. Since its establishment in 2011, it has accumulated many years of PCB assembly and manufacturing experience, capable of efficiently transforming customer designs into mass-produced electronic products. Next, let's learn more about the PCBA contract manufacturing services provided by PCBasic. First, let's take a look at the relevant introduction of PCBA contract manufacturing.

PCBA contract manufacturing refers to outsourcing PCB assembly to a professional contract manufacturer. Reliable PCBA contract manufacturers typically handle component sourcing, PCB assembly, electrical testing, and final delivery. Besides the specific manufacturing execution, the manufacturers will also participate in technical support, such as manufacturability assessment, process control, and implementation of industry standards. Through this cooperation method, the product team can focus more on design and product advancement, while the stability of production quality is also guaranteed. This is also the reason why many enterprises prefer to cooperate with professional contract manufacturing companies.

PCBA contract manufacturing services are an important part of EMS (Electronic Manufacturing Services). PCBA contract manufacturing mainly focuses on the assembly and testing at the circuit board level, while EMS covers a broader range of manufacturing processes on this basis.

In the EMS system, the contract manufacturing of PCBA plays a fundamental role, covering aspects such as component procurement, PCB assembly, and quality verification. EMS further expands on this basis, providing services such as system integration, complete assembly, logistics coordination, and full life cycle support for products.

Enterprises can either choose to solely engage in PCBA contract manufacturing services to complete the assembly of circuit boards. As their manufacturing needs evolve, they can upgrade to a full electronic contract manufacturing model. In summary, PCBA contract manufacturing and EMS cooperate with each other to jointly form a complete electronic manufacturing solution.

Typically, the professional PCBA contract manufacturing process includes (taking PCBasic as an example below):

1. Design review and BOM assessment

PCBasic will first analyze the customer's manufacturability design (DFM)/assemblability design (DFA) to ensure the manufacturability of PCB assembly. At the same time, through strict BOM verification, potential production risks will be eliminated.

2. PCB incoming material inspection

Subsequently, a rigorous incoming material inspection is conducted for the PCB to ensure compliance with the standard requirements.

3. Component Sourcing

Next is component sourcing. PCBasic has reliable channels for purchasing components, which can reduce the risk of using counterfeit or outdated components.

4. Component Pre-treatment

Before being mounted, the components also require professional pre-treatment (such as baking, pin trimming, solder paste application, etc.) to provide the best soldering conditions for the subsequent PCB assembly process.

5. PCB Assembly

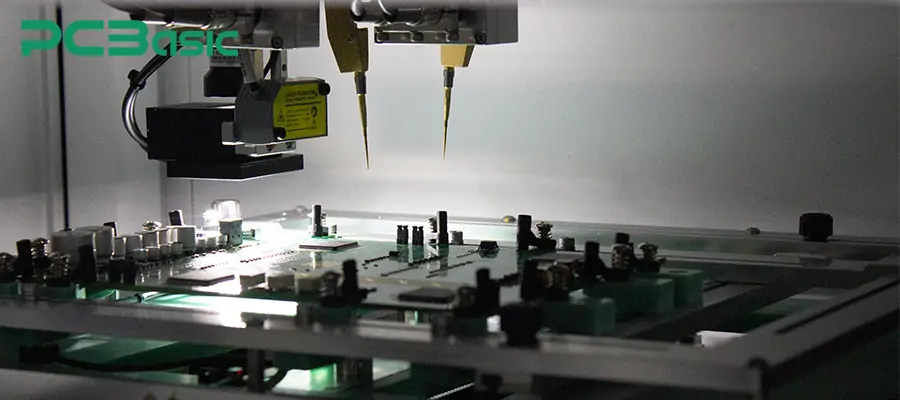

The high-precision SMT production line and controllable DIP process are crucial for achieving stable soldering quality. This demonstrates the core strength of the PCB contract assembly manufacturer.

6. Post-soldering treatment

The cleaning process that complies with the EU RoHS standards and the repair of defective solder joints can enhance the reliability of PCBA products in the electronic contract manufacturing market.

7. Inspection and Testing

Automated optical inspection (AOI), X-ray inspection, and functional testing are used to verify the performance of the products. This is a crucial part of the quality control process for any PCB assembly manufacturer.

8. Reliability Testing (Optional)

Based on the specific electronic contract manufacturing service requirements of the industry, customized reliability tests (such as temperature cycling, vibration, and humidity tests) will be provided.

9. Packaging and Delivery

PCBasic offers anti-static packaging and traceable logistics support, enabling it to serve customers worldwide.

10. After-sales Service and Technical Support

A professional PCBA contract manufacturer should have comprehensive after-sales services to ensure a long-term cooperative relationship with customers.

Quality is the foundation for long-term cooperation in the field of electronic assembly manufacturing. As a professional PCBA contract manufacturer, a reliable PCBA supplier, and a Chinese PCBA contract manufacturer, PCBasic integrates strict quality control into every aspect of its contract manufacturing services.

The core quality measures include:

Incoming material inspection of PCBs and components

Process monitoring during SMT and DIP assembly

Electrical and functional testing of finished components

Traceability management throughout the entire production process

These measures help our partners reduce rework, avoid on-site failures, and maintain product reliability, further enhancing our reputation as a trustworthy PCBA contract manufacturer.

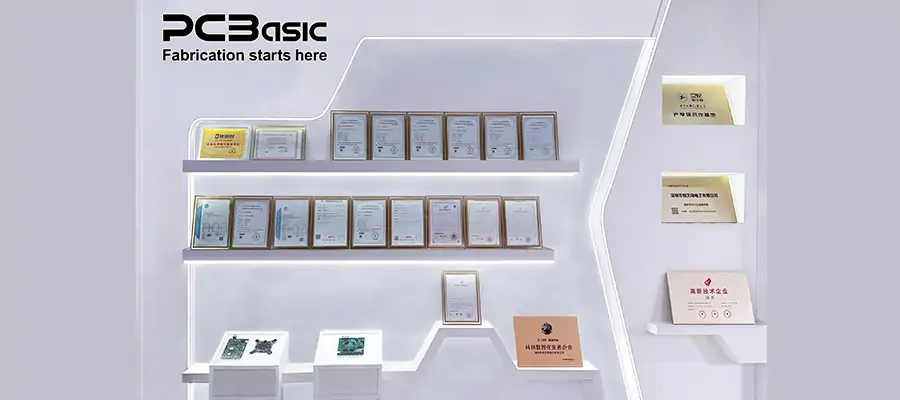

A professional PCB assembly contract manufacturer must adhere to international standards in order to provide high-quality contract manufacturing services and PCB contract assembly services. PCBasic has:

ISO 9001

ISO 13485

IATF 16949

Compliance with RoHS and REACH regulations

See the following figure:

These certifications support global market access and enhance the credibility of our contract manufacturing services.

PCBasic can customize corresponding contract manufacturing services based on the specific application requirements of customers, such as:

Industrial automation - high reliability and long-term lifecycle support

Automotive electronics - strict process control and traceability

Medical equipment - clean assembly environment and compliance

Consumer electronics - cost-effective and scalable assembly manufacturing

This flexible manufacturing service enables PCBasic to serve customers as a long-term PCBA supplier in multiple markets.

Among the numerous contract manufacturers, PCBasic stands out for its excellent balance in terms of quality, speed and cost-effectiveness. PCBasic has several advantages:

Having a seasoned in-house engineering team

Possessing strong procurement capabilities

Being able to provide flexible support from prototype design to large-scale production

Own factories, transparent communication and efficient project management

All of the above advantages clearly demonstrate that PCBasic is a reliable professional PCBA contract manufacturer.

Whether you need a reliable PCBA contract manufacturer, a flexible PCB assembly partner, or a trustworthy electronic assembly manufacturing solution in China, PCBasic will be more than happy to provide support for your project.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.