Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Overview of PCB SMT Assembly

In the dynamic world of electronics, PCB SMT assembly plays a crucial role in bringing modern devices to life. Whether it's a prototype PCB assembly for a new gadget or high-volume production for medical equipment, the efficiency and precision of SMT assembly are unmatched. This article delves into what SMT is, the intricate process behind it, and how PCBasic leverages advanced automation equipment and SMT machines to deliver exceptional circuit board assembly services.

Surface Mount Technology (SMT) is a method of placing and soldering electronic components directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole technology, SMT eliminates the need for drilling holes in the board, making the process faster and more cost-effective. SMT revolutionized the electronics industry, enabling the creation of compact and lightweight devices.

The PCB SMT assembly process involves several carefully coordinated steps, each critical to achieving high-quality circuit board assembly. Below is a breakdown of the stages:

1. Solder Paste Application

The process begins with applying solder paste onto the PCB. A stencil ensures that the paste is placed accurately on the pads where the components will be mounted. High-quality solder joints depend on the precision of this step.

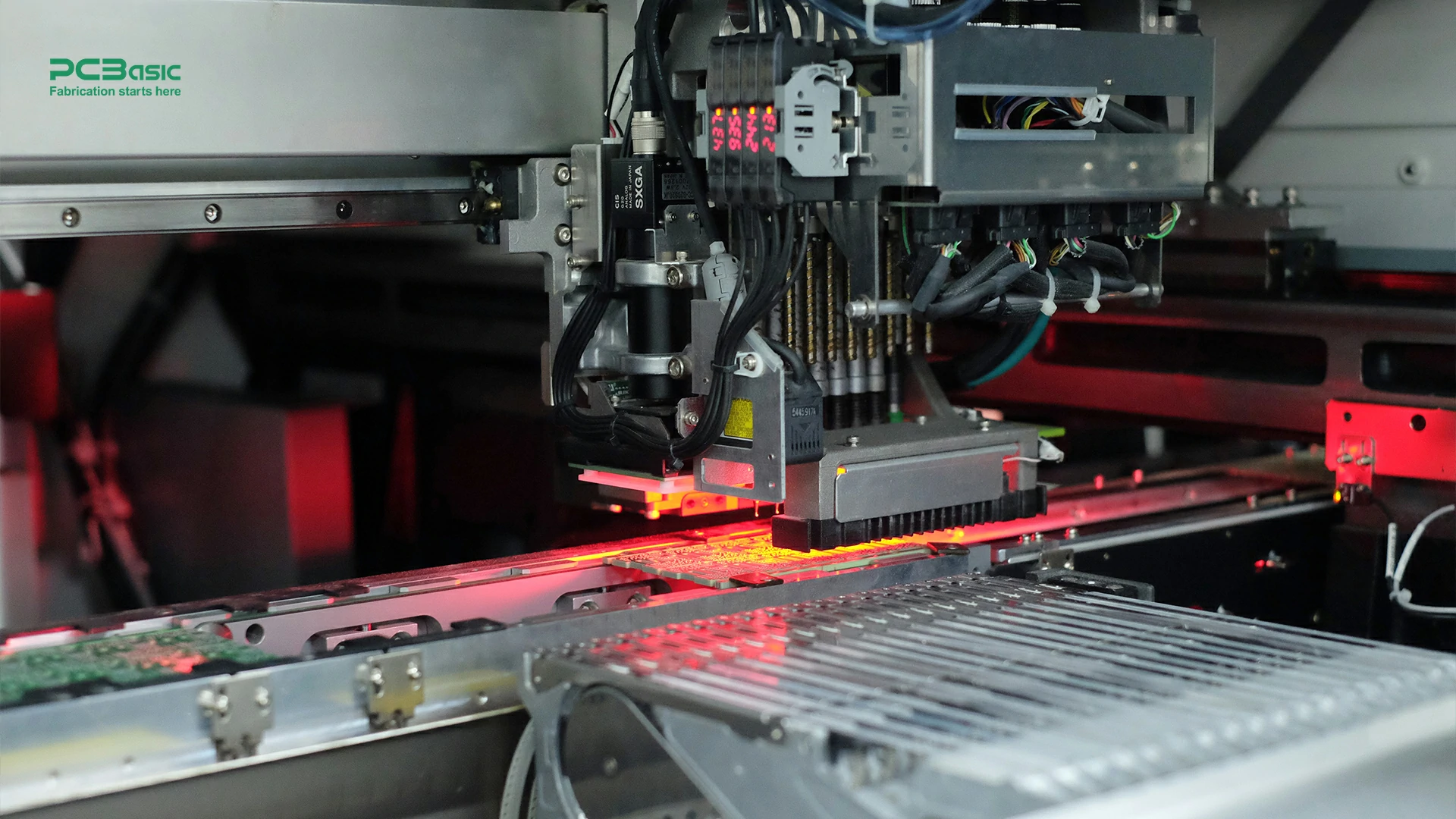

2. Pick and Place

Using advanced SMT machines, components are picked from reels or trays and placed onto the PCB with extreme accuracy. This step is highly automated, ensuring speed and reducing errors.

3. Reflow Soldering

The PCB, now loaded with components, moves into a reflow oven. Controlled heat melts the solder paste, creating strong solder joints that secure the components to the board. This step is critical for the durability and functionality of the circuit board.

4. Inspection and Testing

After reflow soldering, the PCB undergoes thorough inspection using automated optical inspection (AOI) and X-ray systems. This ensures there are no defects, such as misaligned components or faulty solder joints. Functional testing may also be conducted to verify the circuit board's performance.

5. Final Assembly and Packaging

For some boards, additional assembly steps like through-hole component soldering or manual adjustments may be required. Once complete, the PCB assembly is packaged and prepared for delivery.

PCBasic stands out as a leading PCB assembly manufacturer, offering end-to-end assembly services tailored to a variety of industries. From prototype PCB assembly to large-scale production, our company ensures precision, speed, and quality in every project.

Advanced Automation and Technology

At PCBasic, we leverage state-of-the-art SMT machines, automation equipment, and intelligent management systems like MES, ERP, and IoT to streamline the SMT assembly process. Our facilities include:

Expertise in Diverse Industries

With over 15 years of experience in circuit board assembly, PCBasic serves industries like medical devices, automotive electronics, industrial control, and smart home applications. Our expertise ensures that every printed circuit board assembly meets stringent industry standards.

Quality Certifications

PCBasic has achieved ISO9001, IATF16949, and ISO13485 certifications, reflecting our commitment to quality and excellence. Our team includes over 30 PCB designers, 20 quality management personnel, and 10 IT specialists, all dedicated to delivering exceptional circuit board assembly services.

Turnkey PCB Assembly Services

Our turnkey PCB assembly approach covers everything from PCB design and material sourcing to manufacturing and functional testing. This comprehensive service model ensures seamless project execution and reduces lead times.

Prototype PCB Assembly

For businesses needing rapid development, our prototype PCB assembly services provide quick and reliable solutions. We understand the importance of speed in innovation and have tailored our processes to meet these demands.

Commitment to Quality

Our self-developed inspection and testing systems, including LCR incoming inspection and SMT fault detection, enhance the reliability of every PCB assembly. These systems ensure that every smd PCB assembly we deliver is free from defects and ready for integration.

The efficiency and precision of PCB SMT assembly have revolutionized modern electronics, enabling the creation of compact, reliable, and high-performance devices. With PCBasic, you get a trusted partner that combines cutting-edge technology, extensive expertise, and a commitment to quality in every circuit board assembly project.

Whether you need prototype PCB assembly, turnkey PCB assembly, or large-scale production, PCBasic is the PCB assembler you can rely on. Our advanced automation equipment, expert team, and industry certifications make us a leader in SMT assembly and circuit board assembly services.

Partner with PCBasic for all your PCB assembly needs and experience the difference that precision, quality, and innovation can make.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.