Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > JST Connector Types: A Guide to 2-Pin, 4-Pin & More

In order to run well, any electronics needs to be accurate and trustworthy, and a significant percentage of that depends on JST connectors. Connectors, which are produced by Japan Solderless Terminals (or JST), have been praised for their reliability, convenience, and other elements. They are also widely used in various household electronics and industrial systems.

This guide is to help you demystify this connector by giving a brief overview of the different types, features, and benefits of JST connectors. So you'll learn about some crucial options you have when it comes to JST 2-pin and 4-pin connectors, as well as several tricks you might want to consider to determine what's best for your project. We will also talk about the pros of their usage in PCBs and their usage in several industries.

The truth about whatever you plan on applying those JST connectors to, whether in your electronics engineering, PCB projects, or even to some aspiring amateurs just venturing out into using them. These connectors do actually make the kind of connections more effective and reliable in some way.

The JST connector (Japanese Solderless Terminal) is a great small terminal made by Japan Solderless Terminals Co. JST wiring, safety, and performance between wires and PCBs is one of the hot topics in modem electronics.

JST connectors are suitable for signal transmission in a flexible way, and they are perfect for powering devices stably. They are plug-and-play and , therefore, flexible to the wide variety of configurations that various products present. Different sizes are needed for different mating, which is why they are available.

● The device size achieved considering the design space for area-constrained implementations.

● National Instruments data acquisition systems can withstand shocks and vibrations very well.

● This also impacts negatively the time of assembly at the manufacturing level.

● The thousands make pin counts and pitches with great variety for any number of purposes.

Numerous forms of electronic systems have been selected as excellent and dependable parts due to the abovementioned stuff.

These connectors are designed to be used in all sorts of applications in electronic gadgets. JST connectors basically fall into different categories depending on pin configuration, connection types, and pitches. Some of the popular types of JST connectors and their subcategories are described below.

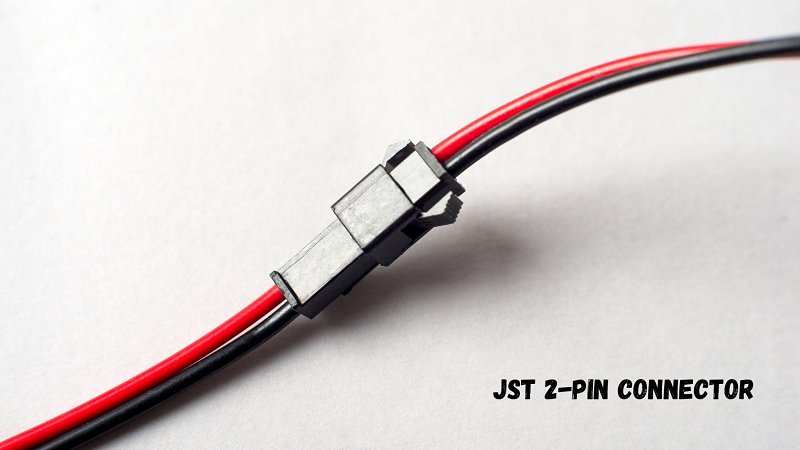

They're pretty simple yet effective for low-power applications. They're used commonly in small electronic devices, where a compact and reliable connection is needed in the prevalent wire-to-wire and wire-to-board configurations.

With more versatility, 4-pin connectors find their use in situations needing more than one signal or power line. They are commonly used for LED lighting and communication modules.

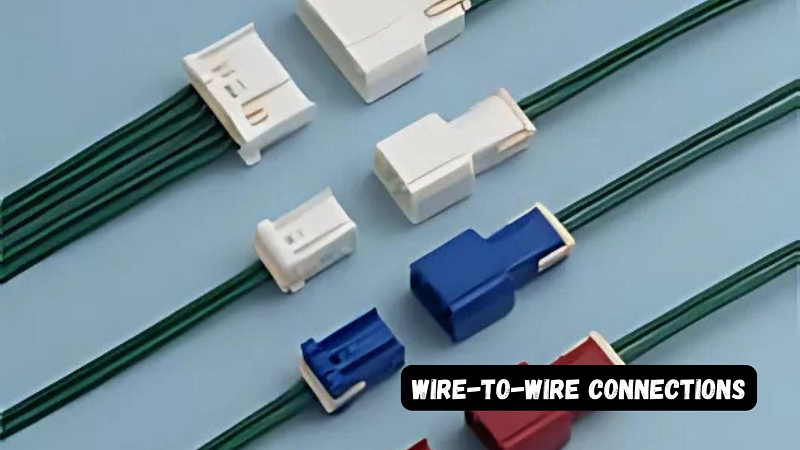

Wire-to-wire JST connectors are directly connected between wires and are perfect in tight spaces where flexibility is needed.

Compact wire-to-wire connectors for medium-power applications have become popular in LED strips and other consumer electronics.

Having a strong build, this connector is mostly used in rechargeable battery packs and remote-controlled devices.

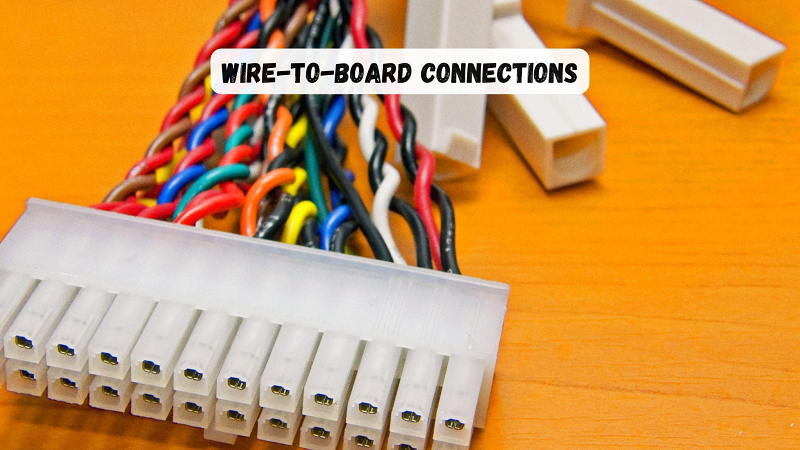

Wire-to-board connectors are utilized to connect cables directly to PCBs for the effective transmission of power and signals. The following types are for use in various applications.

SR/SH (1mm Pitch): So tiny are these connectors that they are highly suitable for high-density applications, finding the best application in small PCB designs where space is not adequate.

SHD (1mm Pitch): This is a dual-row derivative of the SH connector with increased pin count in a still smaller package, more suitable for more complex designs.

GH (1.25mm Pitch): They find application in various places because of the strength and adaptability that their GH connectors have proved to offer where space is limited and mechanical robustness is needed.

ZH (1.5mm Pitch): Since the ZH connector had a good balance between size and power-carrying capability, that connector would also be worth your attention in cases where both aforementioned requirements have been of equal importance.

PA (2mm Pitch): It fits much more tightly by a locking mechanism than the PA connectors applied to automotive and industrial applications, where the connections have to be strong and robust.

PH (2.0mm Pitch): These are the types of connectors that find extensive usage in consumer electronics, compact in size but at no compromise on performance.

XA (2.5mm Pitch): These are low-current type connectors and are targeted to provide reliability in the appliance market, including small appliances.

XH (2.5mm Pitch): General-purpose when it comes to connectors, the XH series has been known for tough performance in establishing a secure connection across the board for a wide number of applications.

EH (2.5mm Pitch): EH is a simplified version of the XH series, providing excellent cost reduction for applications where basic, affordable connectivity suffices.

RE (2.54mm Pitch): Primarily used as a development and general electronics platform, so RE connectors are designed to be used on standard PCB layouts and, hence, very easy to use for most applications.

VH (3.96mm Pitch): VH connectors are their high-current, heavy-duty versions; the application, concerning strength and robustness, is mainly directed toward industrial equipment.

Each of the connectors discussed has a special role in designing robust and performing connections between PCBs and wires to meet the demands of various industries and applications.

JST connectors are targeted at a broad range of electronic applications, and their specifications enable them to be highly versatile and reliable in the fabrication of PCBs. The following are key points that describe their performance.

The pitch means the actual space between the centers of two successive pins.

JST connectors are available in pitches ranging from 1mm for ultra-mini designs up to 3.96mm for wide load currents.

Larger pitches are inversely related to how favorable they are for use within high-density PCB designs. Larger pitches have proven to be more favorable when approaching large power and industrial applications.

● Current Ratings: The JST connectors are rated from 1A to 10A depending on the series, which in principle should be sufficient for lower- to medium-power applications.

● Voltage Ratings: Mainly rated in the range between 50 and 250V, hence applicable to many electronic devices from consumer products to industrial systems.

JST connectors come in many different wire gauge sizes, but most common power and signal transmissions are done within AWG 28 to AWG 16 wire gauge.

Thicker wires are a better option for high current flow, but as the wires get thinner, they provide a better option for fitting into limited spaces in the design.

● Shrouds: The housing can be shrouded to keep the pins away from being abraded during mating or mismatched.

● Locks: The locking mechanism provides extra reliability against mechanical disconnection due to application vibration (e.g., automotive and industrial equipment).

Due to the extensive benefits of these JST connectors, they are the most used in PCB assembly. Here is why:

Connections at JST connector types are well built and robust, with limitations of signal degradation/cut or outage of power, making it common to forget their existence; the locking mechanism between the arduous outer casing & the shroud design of every male/female component enhances reliability & well-built connectors for specific environments where strength due to stability matters.

Since JST connectors can also be of any size, pitch, and geometry, they lend themselves to any PCB layout. Whether you need the smallest sizes in space-constrained applications or bulk connectors in automotive and medical applications, JST offers solutions that fit almost every application value.

JST connectors are robust or durable, which leads to lesser maintenance and a longer life for the product as a whole. This reduction in cost is even more when the processes of automatic assembly are compatible, as in the case of mass manufacturing or larger projects.

The reason is that JST connectors are a preferred choice over most other connectors due to their versatility and reliability. Now, deep-dive into use cases for them:

The JST connector became an important part of consumer electronics, as the small and efficient designs meant that power connections could be supplied to relatively small devices which allowed batteries, displays, keyboards, and internally powered circuits of laptops to integrate nicely together.

JST connectors are being utilized for power and accuracy in modern cars. These connectors perform very important roles in modern automotive electronics, enabling critical components of an automobile such as sensors and cameras and, notably, in modern electric vehicles, the battery management system.

Industrial environments require extremely reliable and robust connectivity solutions. Digital Controllers & Perfect Fit for Automated Machines with Operation Under Heavy Conditions The JST Connectors are working wonderfully in control structures for automated machines and withstanding the workload conditions of the equipment.

Damned if you do, damned if you don't. The JST chooses a field of application in medical fields that fits the bill for reliability: they can also be seen in various diagnostic hardware types that demand precision and compactness, as seen in imaging systems and wearable healthcare devices.

– In aerospace and aviation applications, high requirements are imposed on connectors; the wide range of systems installed on board, such as flight control devices or communication devices, reinforce the reliability of their functions, with the most demanding special application implemented at level-2 standards is the satellite.

JST connectors can be a lifesaver when wiring up LED lights as they make it a hell of a lot easier and add more design freedom since their small form factor fits right into more complex lighting solutions.

Suitable and suitable JST connectors should be selected with proper consideration of the factors below:

● Dimension: Matches the overall design and layout restrictions of the PCB.

● Electrical Requirements: Appropriate current and voltage ratings if application conditions govern.

● How environment compatibility suits the lock: Environmental considerations lead to more intricate mechanical lock designs and strong connector case designs for very high-end environments.

Integration is much more than the selection of a component:

● Footprint Design: Manufacturer specifications enable precise PCB layouts.

● Placement Strategy: With minimal interference, provide the most connectivity.

● Routing and soldering: Proper routing paths and soldering techniques provide stable connections.

The JST connectors can be a little finicky sometimes. This is because the loose connections are deemed unreliable, and from then on, the mating and locking system verification will keep going on. Extra pins that could be damaged as a replacement. Wiring issues need super-cautious verification with schematics.

Knowing connector terminology is fundamental. Here's a brief glossary:

|

Term |

Description |

|

Gender |

Refers to male (pins) or female (sockets) parts of the connector. |

|

Polarity |

Ensures proper orientation to prevent reversed connections. |

|

Contact |

The conductive element in a connector that makes the connection. |

|

Pitch |

Distance between adjacent pins is measured in millimeters. |

|

Mating Cycles |

Number of times a connector can be mated/unmated without degradation. |

|

Mount |

Type of connector attachment to the PCB, such as through-hole or SMT. |

|

Strain Relief |

Reduces stress on wires, preventing damage and disconnections. |

|

Male/Female |

Male connectors have pins; female connectors have corresponding sockets. |

|

Pin/Socket |

The pin is the male conductive part; the socket is the female part. |

|

Housing |

The insulating substance around the pins or sockets. |

In a nutshell, JST connectors are among the best in providing service in PCB fabrication, in flexibility for a range of applications, but never at the expense of dependability and ease of operation. Thus, engineering will dramatically improve with such connectors when it comes to consumer products, automotive technology, or even industrial equipment.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.