Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What is Aluminum PCB? | PCB Knowledge

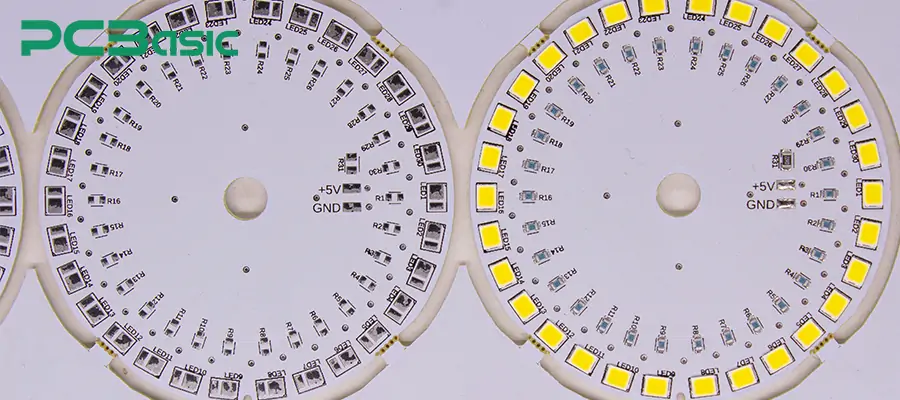

Aluminum PCBs, as one of the metal core PCBs, have high thermal conductivity, mechanical strength, and power dissipation. Unlike ordinary fiberglass or plastic PCBs, the substrate of these PCBs is aluminum, which is credited to heat dissipation. They are, therefore, ideal for use in LED lighting, automotive electronics and telecommunications applications.

Since energy-saving technologies are being implemented, aluminum-based PCBs such as high-power LED devices have also been used with circuits that generate lots of heat. This guide looks at its construction, different types, features, applications, and growing demand for PCBs. Now, without further ado, let's head straight into understanding aluminum PCB knowledge.

Aluminum PCB is a printed circuit board with an aluminum base to provide the mechanical strength and thermal properties needed for power applications like LED and integrated circuits. Heat is a critical parameter, especially when the device's physical form is small but the power is increased. To ensure the aluminum substrate PCBs are functional for a long time, it should be made sure that they are stored in environments with low humidity and temperature because oxidation is destructive for the aluminum base PCB and the copper circuit layer.

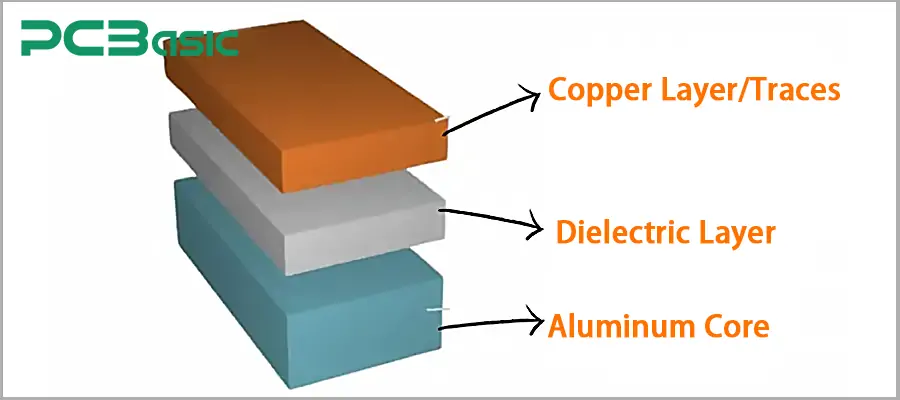

Typically, aluminum PCBs consist of three main layers:

Copper Layer:

The outer layer, as we all know, is made of copper to allow the flow of electrical signals. This layer is thicker than any other layers in the PCB with the view of carrying higher current and proper heat distribution, hence the higher ratio. The next step is to put another copper layer, which is located above the dielectric layer and below the aluminum body.

Dielectric Layer:

Also, an intermediate barrier plays the role of the insulating barrier of copper and aluminum substrate. It mainly offers an electrical insulation function and conduct channels where heat from the copper layer is transferred to the aluminum base. The dielectric layer materials are chosen to be low thermal conductivity materials. At the same time, the material's electrical characteristics are also taken care of.

Aluminum Base:

An aluminum PCB has an aluminum substrate, an essential component of such a PCB. This part of the design is also metal, which offers metal core PCB mechanical strength and aids in dissipating heat from electrical components. It is most valuable for high-power applications and where heat generation occurs.

Thus, these three layers combined create a lightweight and heat-proof PCB, which is capable of handling higher power densities than fiberglass-based PCB.

Like other PCBs, aluminum PCBs have different types as well. The four common types of aluminum PCBs are:

Single-Sided Aluminum PCB:

Aluminum base material is used as its primary part, and a single layer of conductive copper is laminated at the top. Aluminum is widely used with LED applications to provide heat sinking for applications with high power needs.

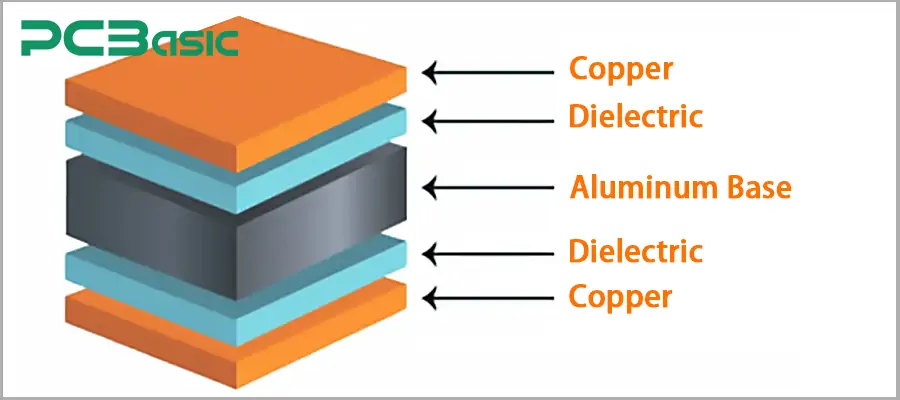

Double-Sided Aluminum PCB:

This form has two layers of copper on both sides of the dielectric layer, thus allowing the formation of complex circuits. Its aluminum base is in the middle position, and there is a good heat flow in the right direction.

Multilayer Aluminum PCB:

Multiple-layer Aluminum PCBs are used in manufacturing for other sub-technical applications. These include a set of copper circuits sandwiched between polydielectrical ones and an aluminum substrate. The multiple layers permit more circuit density due to the unique aluminum base, which everyone can use for the thermal properties of copper.

Flexible Aluminum PCB:

The other developing technology is flexible aluminum circuit boards that can be bent or folded. They are ideal for applications where space is a limiting factor, or the board must be placed in specific and unique angles, as in automobiles and wearable electronics.

Material is one of the most critical elements of an aluminum PCB performance. The quality of the materials used in construction enables a high-quality, high-end performance. Here are the essential materials:

Aluminum Substrate:

It is positioned at the lower side of the aluminum PCB, and its primary role is to provide mechanical support and help remove heat. Aluminum is preferred due to its relatively lower cost than metals like copper, which is lighter but more robust.

Dielectric Layer:

The dielectric layer is between the copper circuit layer and the Aluminum base. High thermal conductivity is needed here as it should conduct heat from the copper layer to the Aluminum base, but at the same time, it should not trigger a short circuit.

Copper Circuit Layer:

This layer sends electrical impulses across the board or horizontally performs impulses. It can be as thin as several molecules, and the thickness of the layer may vary depending on the specificity of the application of the layer. At high power levels, copper circuit layers are heavier to handle the load current and heat production.

The performance of aluminum PCBs depends on their thermal management characteristics, based on which their performance is evaluated. In high-power applications, heat poses a problem for electrical parts and circuits. It increases their degradation rate, makes the entire system perform poorly, or results in total system breakdown in the worst case. These problems are typically addressed in aluminum PCBs because they absorb more heat than fiberglass PCBs.

In addition, aluminum printed circuit boards have much better mechanical performance, which can enhance the physical performance and environment of the printed circuit. It is helpful in cases such as automobile electronics since these are susceptible to vibrations and changes in temperature.

From an electrical point of view, we have a conducting layer drawn from copper, which enables signal transfer and a dielectric layer, which prevents shorting. Overall, aluminum PCB is an excellent thermo-electrical composite with strong mechanics that allow it to stand in high endurance.

Superior Heat Dissipation:

Aluminum PCBs could be effectively utilized because of their main advantage of massive thermal dissipation capability. This makes them useful in applications where heat dissipation is critical, including LED lighting and power electronics.

Mechanical Stability:

Aluminum PCBs, for that matter, are considerably more serviceable than fiberglass boards. The base is made of aluminum, which reinforces the metal core board, making it less susceptible to vibrations, impacts, and temperature fluctuations.

Lightweight Design:

Aluminum PCBs are relatively lighter than other metal PCB base solutions, although they are also made of metal. It makes them suitable for applications requiring a balance between the heat sink and the total mass of a system.

Eco-Friendly:

Being able to be reused is another feature of aluminum PCBs, which makes aluminum PCBs more environmentally friendly than any other types.

Higher Manufacturing Costs:

Aluminum PCBs are more costly than the common fiberglass boards because of the materials and techniques used.

Limited Design Flexibility:

Aluminum PCBs offer excellent thermal conductivity and mechanical strength, but their design is inferior to standard PCBs, especially in thick circuits and multilayer boards.

Challenges associated with the production of aluminum PCBs are as follows: Aluminum PCBs have a different structure and materials. These barriers include accessibility of specialized equipment and sophisticated quality control tests, which affect costs and productivity.

Specialized Equipment:

Another disadvantage is that aluminum is very abrasive and requires much pressure on the drilling and cutting tools, which makes the cost of production of the PCBs high.

Dielectric Layer Uniformity:

The dielectric layers should also be uniform, so there is no local heating, and the material properties should possess favorable electrical and thermal properties.

Lamination Process:

This is a challenge when one wants to ensure good contact between several layers, which may lead to poor mechanical strength of the board and poor thermal management.

Complex Quality Testing:

The quality control algorithm involved in aluminum printed circuit boards is complicated due to their electrical and thermal load testing process.

Aluminum core PCBs are widely used in various technologies because of their excellent heat transfer and mechanical strength. They are favorable for applications where heat dissipation is most important due to their properties.

LED Lighting:

Aluminum PCBs are used in LED lighting circuits, giving the LED board a lot of configuration. LEDs are known to produce quite a lot of heat. While aluminum PCBs are known to aid in dissipation, they can help the lights have a longer life span.

Automotive Electronics:

Aluminum-based PCBs are used within automobile electronics applications such as headlamp assemblies, stop lamp assemblies, and engine management systems. Due to high thermal conductivity and mechanical strength, Aluminum PCB substrates are widely used in automotive applications.

Power Supplies:

Aluminum PCBs also serve in circuits that involve power supply, where the high current components, such as transformers and inductors produce the heat.

Telecommunications:

In the telecommunications sector, aluminum PCBs are employed in equipment like high-frequency amplifiers, where the system produces a lot of heat during work.

Industrial Equipment:

Application areas of aluminum PCB include industrial control systems, motor controllers, and power inverters.

If you are looking for an aluminum PCB manufacturer, PCBasic is one of the most trusted and prominent metal core PCB manufacturers. With 15 years of SMT industry experience, they offer PCB prototyping solutions for various applications.

Some 200-plus employees have expertise and ensure valuable decision-making for you. Suppose you need a single-sided aluminum PCB for LED lighting or a multilayer PCB for complex electronic circuits. In that case, PCBasic has a specialist who can provide the proper products to meet the required quality and reliability.

They also offer online PCB design, manufacturing, and assembly, focusing on speed, quality, and advanced PCB technology. Their core services cover industrial control, smart home, instrumentation, IoT, communication power, medical devices, automotive electronics, and aviation. Welcome to PCBasic!

Aluminum based PCBs are relatively new in the electronics market and have enhanced thermal, mechanical, and electrical characteristics. In electronics throughout the illumination, including LED systems and automotive electronics, telecommunications, and various other high-power applications, an aluminum PCB can be a valuable addition to your products.

In applications from LED lighting to industrial equipment and automotive, these metal core PCBs answer the equipment's heat problems and reliability requirements. If you need aluminum PCBs for your products, you could contact a firm like PCBasic.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.