Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Our integrated manufacturing process shortens the lead time for custom part sourcing, ensures stable delivery, and guarantees consistent quality.

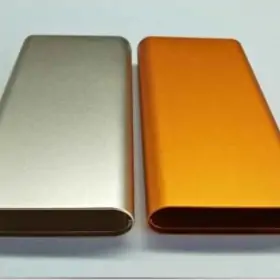

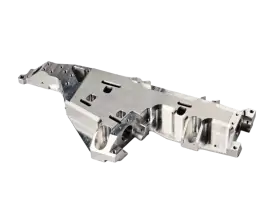

Milling (3-axis, 4-axis, and full 5-axis), turning, and post-processing

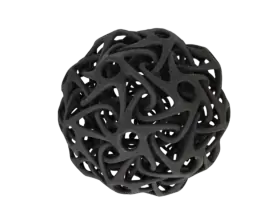

High-precision SLA printing with smooth surface finish

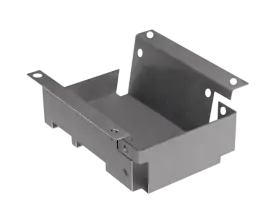

Laser cutting, bending, and post-processing

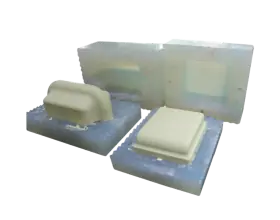

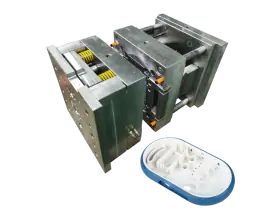

Rapid tooling, family molds, multi-cavity molds, and secondary molding

With rapid tooling, family and multi-cavity molds, ideal for high-volume, repeatable plastic part production.

Every part we make reflects our dedication to precision engineering, quality assurance, and on-time delivery.

For the past 15 years, PCBasic has remained focused on technological innovation and

service improvement, delivering high-quality CNC machining products and custom parts

and earning the trust and praise of customers across the world.

80.5%

Design &

procurement time

Shorter

99.5%

Delivery

On time

98.7%

Quality

Satisfactory

Alexander Price

2025.04.15We’re in the aerospace sector, so machining precision is absolutely critical for us. PCBasic helped us manufacture a batch of titanium alloy turbine housings, with tolerances consistently held within ±0.005mm. They even took the initiative to optimize the toolpaths, cutting our machining time by about 18%. During first article inspection, their engineers were on-site and provided the test report immediately. That level of professionalism gave us real confidence. We’ve already renewed our annual contract with them.

David Thompson

2025.04.10PCBasic turned out to be the right choice for our medical-grade parts. They machined our 316L stainless steel components to a mirror finish that fully met ASTM F138 standards. Surface roughness reached Ra 0.2μm, better than any vendor we’ve worked with before. Their Class 100,000 cleanroom and batch-level material traceability helped us pass the FDA audit smoothly. We’ve already recommended them to others in the industry.

Sarah Collins

2025.04.08We’re developing collaborative robots, and our part designs change pretty frequently. It’s hard to find a CNC factory that can keep up—but PCBasic really delivered. They offered 24-hour rush jobs and even set up video calls with us after every G-code update to double-check everything. One of the latest 7075-T6 harmonic reducer housings they made ran through 48 hours of stress testing with zero issues. The precision met all our lab specs.

If any clarification is needed during the document review, we will contact you via email.

Feel free to email us anytime at JS@pcbasic.com.

Please fill in your name, email, phone number, and upload the required order files.

Tip: Make sure to enter a valid email address to receive your quote.

Once we receive your files, our engineers will review them and prepare a formal quotation. The completed quote will be sent to your email as soon as it's ready.

If you are satisfied with the quote, please confirm by replying to the email. We will start production immediately after confirmation. Once the parts are completed, you can inspect them. After quality confirmation, we will proceed with shipping.

300+

Total Employees

2,000

Self-operated factory

500+

Self-operated factory

High-Precision Measuring Instruments

Advanced CNC technology and precision equipment ensure micron-level accuracy for high-quality results.

High Productivity

Automated, continuous production boosts efficiency and ensures fast turnaround for both low and high-volume orders.

Versatile Machining Capabilities

We handle a wide range of metal and non-metal materials, from simple cuts to complex 3D geometries—tailored to your needs.

Expert Technical Support

Our skilled team offers full-process support—from design to manufacturing—to ensure your project runs smoothly.

Strict Quality Control System

We maintain a comprehensive quality management system. Every part undergoes rigorous testing to meet customer standards and specifications.

Extensive Industry Experience

Since 2011, we’ve specialized in rapid prototyping and precision manufacturing. Our experienced engineers handle a wide range of project types with confidence.

Explore Our CNC Machining and Manufacturing Facility

Can you help modify or optimize designs?

+Do you provide inspection reports?

+Is there a minimum order quantity (MOQ)?

+What materials can you process?

+Do you support international shipping?

+What if the parts are defective?

+3D Printing

Injection Molding Services

Sheet Metal Fabrication Services

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.