Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What Is An SMD in PCB Assembly

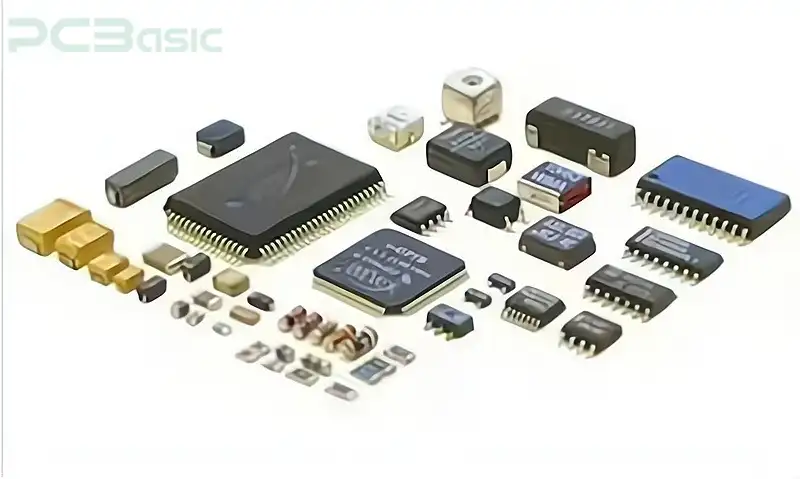

A Surface Mount Device (SMD) refers to an electronic device that is mounted directly onto the surface of a printed circuit board (PCB). The key characteristic that sets SMD apart is its physical design. Unlike traditional components that often have long leads extending through holes in the PCB (known as through-hole technology), SMDs are typically smaller and may not have any leads at all.

The size reduction achieved through the use of SMDs allows for higher component density on PCBs, enabling manufacturers to create more compact and efficient electronic devices. Another defining feature of SMDs is their broad range of shapes and sizes, accommodating various applications and catering to different performance needs. Surface mount technologies incorporate various component types, including resistors, capacitors, and integrated circuits, all designed for surface mounting.

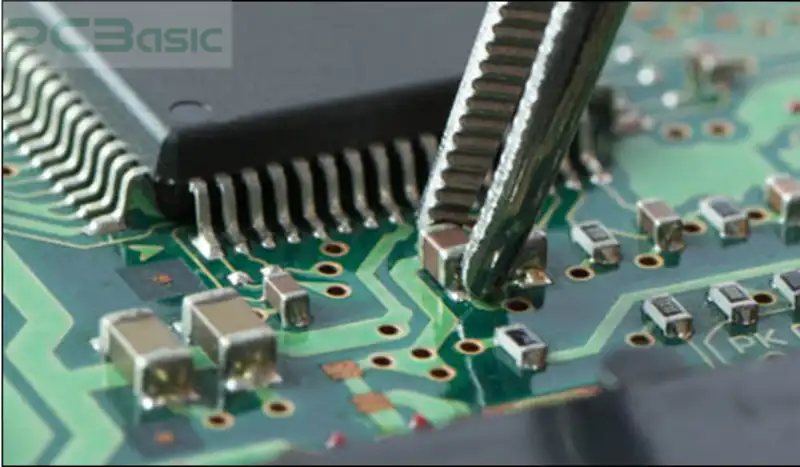

Through-hole technology involves inserting leads of an electronic component through drilled holes in the PCB and soldering them on the opposite side.

In contrast, SMD technology mounts components directly onto the surface, which

grants several advantages.

Key Differences:

SMDs find significant applications across numerous sectors,

including consumer electronics, telecommunications, automotive, and medical

devices.

For instance, in consumer electronics like smartphones and laptops, SMDs

contribute to device miniaturization and improved performance. In automotive

applications, SMDs are used in control systems and sensors.

Similarly, in medical electronics, SMD technology enhances diagnostic

equipment's efficiency, compactness, and reliability.

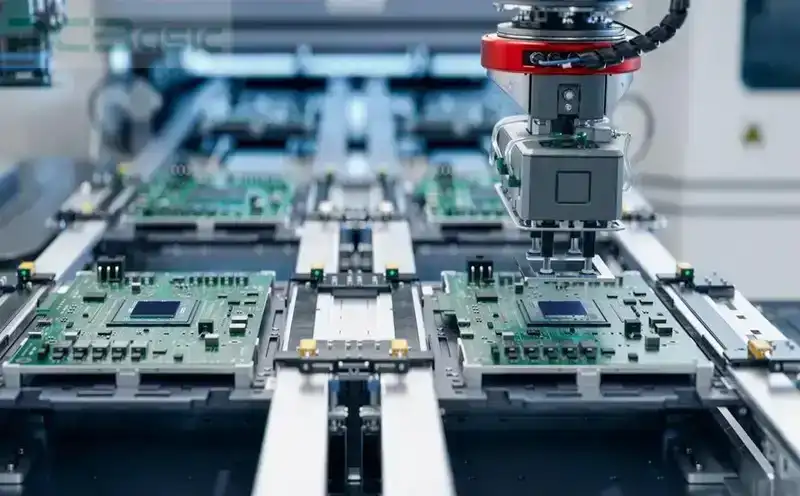

Surface Mount Technology (SMT) is the assembly technique employed to mount SMDs onto printed circuit boards. The primary purpose of SMT is to facilitate a highly automated and flexible process for assembling electronic components, making it easier and more cost-effective to produce modern electronic devices.

One of the standout features of SMT compared to traditional technologies is the elimination of the need for drilled holes, thus allowing for denser layouts on the PCB. SMT supports dual-sided circuit boards, enabling components to be placed on both sides without compromising the device's size or performance.

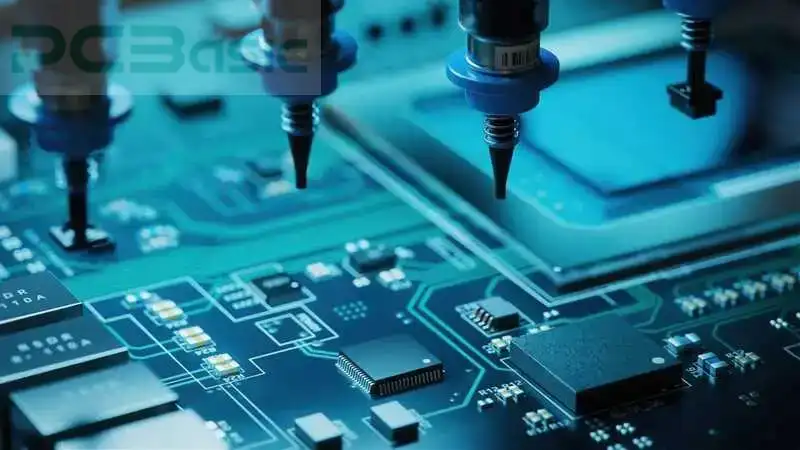

Additionally, it utilizes equipment like stencil printers for applying solder

paste, pick and place machines for component positioning, and reflow ovens to

solder components onto the PCB effectively.

The advantages of SMT over conventional hand-soldered methods are substantial.

Notably, SMT improves manufacturing speed and efficiency, allowing for faster

production cycles, which can significantly reduce labor costs.

Furthermore, advancements in SMT technology have introduced precision equipment

that enhances placement accuracy and reliability, which is critical in

high-performance applications. The development of complex SMDs, coupled with

improvements in SMT processes, has led to greater functional capabilities and

higher overall product quality.

SMD components can be broadly classified into two categories: passive and active components.

In addition to passive and active components, SMD technology also encompasses electromechanical devices, which are integral to establishing connections or performing mechanical tasks on PCBs. Examples include switches, relays, and connectors. These devices play vital roles in controlling electronic systems and ensuring that various components communicate effectively.

The design and manufacturing of SMD components are evolving continuously, with trends such as miniaturization, integration of functionalities, and the use of environmentally friendly materials gaining momentum. More manufacturers are leveraging surface mount technology to design components that meet the demands of modern electronics, focused on enhancing performance while minimizing physical size.

The SMT assembly process consists of several critical steps:

1. Preparation: The PCB is cleaned, and a stencil is aligned on the board to apply solder paste.

Pick and place machines are pivotal in the SMT assembly process, offering high-speed and precise placement of SMDs onto the PCB. These machines utilize sophisticated software to control movements, handle a wide range of component sizes, and ensure accuracy. By automating this process, manufacturers can achieve a remarkable production rate while maintaining quality standards.

Quality control is a critical element in SMT to ensure that products meet performance and reliability standards. The inspection process, which often includes AOI and various functional tests, identifies defects early, preventing costly errors down the line. In a competitive market, maintaining high-quality products through stringent quality control measures is vital to customer satisfaction and business success.

In conclusion, understanding the relationship between SMD and SMT, the intricacies of the assembly process, and the applications of various components allows you to appreciate the significance of surface mount technology in modern electronics. This knowledge can enhance your approach to designing PCB solutions that leverage these technologies effectively, ensuring optimal performance and reliability.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.