Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What is a PCB Assembler: A Vital Role in Modern Electronics

PCB assemblers play one of the most crucial roles in today’s world of electronics. These specialized companies are responsible for transforming bare circuit boards into fully functional electronic devices through the PCB assembly process — a crucial step that brings life to modern gadgets, appliances, medical devices, automotive systems, and more.

The PCB assembly manufacturers will begin with component sourcing and placement onto the board, as well as quality control and final testing, ensuring that every product meets the industry standards set for the particular product to perform, deliver, and last.

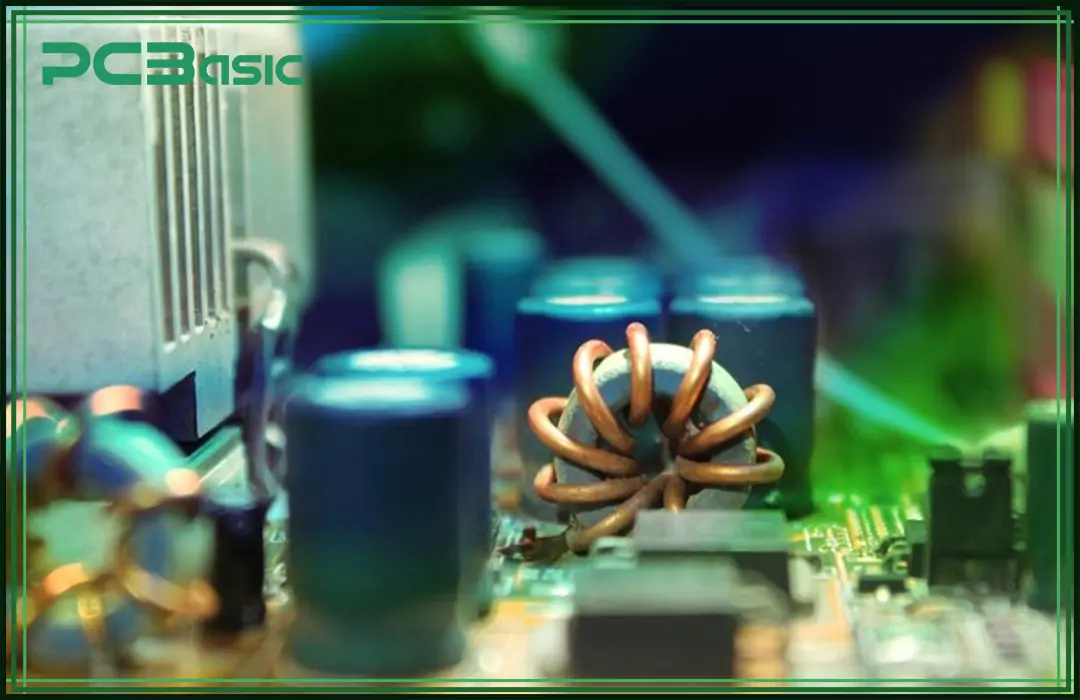

PCB assembly, often referred to as PCBA, is a process of mounting and soldering electronic components on printed circuit boards to create a fully functional electronic device. Unlike bare PCBs which exist as just boards with traces of copper, the completed PCB assembly is inclusive of all the required components, such as resistors and capacitors in addition to integrated circuits and connectors — ready to be used in electronics products.

This process holds a spotlight when it comes to modern electronics manufacturing since everything is shot with precision, reliability, and quality. PCB assembly service providers, including prototypes of PCB assembly and turnkey PCB assembly, are just what you need to transform those design files into working products from consumer electronics to aerospace.

The PCB assembly process incorporates several critical stages, combining both automated machinery and skilled manual work. Here’s a simplified overview:

Paste Application: A stencil will be used in laying solder paste thinly on the bare PCB. It keeps the components in their respective positions before soldering.

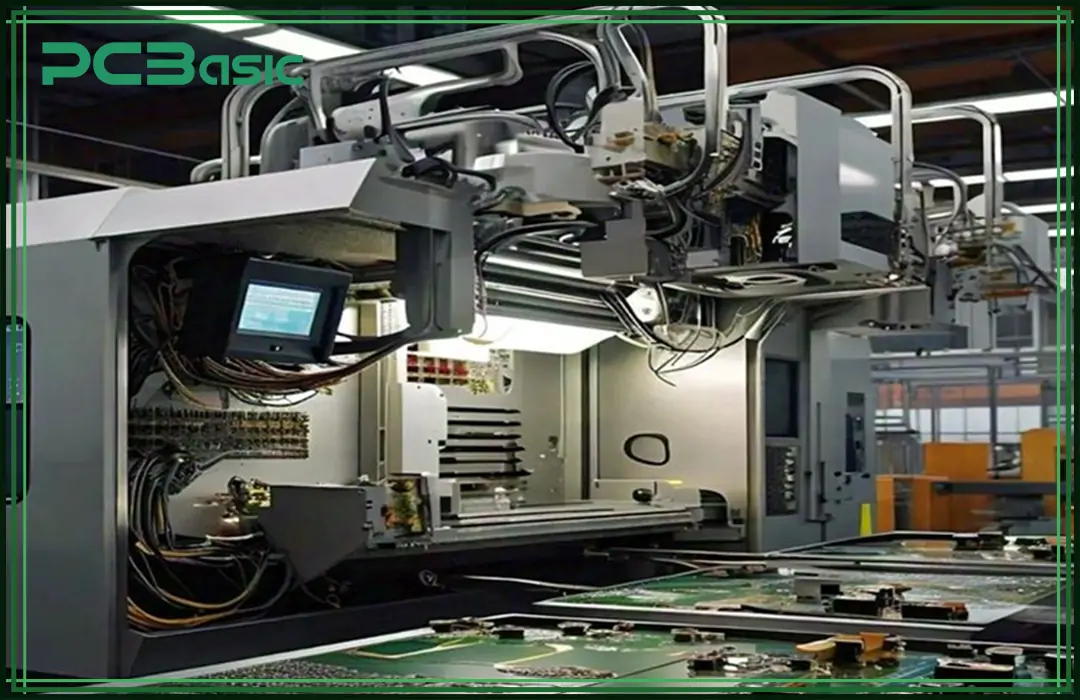

Component Placement: This is what PCB assembly is all about: mount components placed onto the board by automated pick-and-place machines.

Soldering: The board is normally passed straight into a reflow oven for melting the solder paste and creating strong connections when it is for SMT components. Through-hole components may be hand soldered, or go through wave soldering, when present.

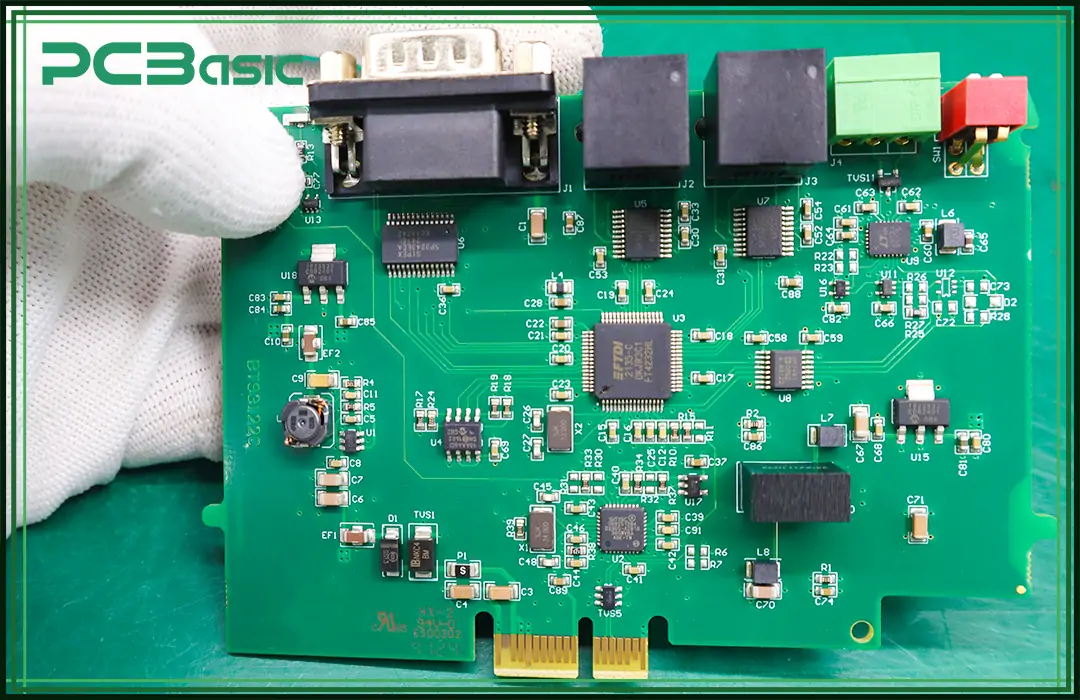

Inspection and Quality Control: High-end PCB assembly manufacturers use optical and X-ray inspection systems to ensure flawless connections at every end. This is critical for product reliability.

Testing and final checks: This is followed by a test of the assembled PCB to ascertain that it functions optimally. Depending on complexity, this can include automatic testing, functional testing, or in circuit testing.

Modern PCB manufacturing and assembly lean entirely on automation and state-of-the-art technology when handling tiny components in sophisticated devices whether prototype PCB assembly for startups or turnkey PCB assembly for large volume production, selecting the perfect service provider in circuit board assembly is of utmost necessity to ensure successful product commercialization.

A PCB assembler is a company or service provider that assembles electronic components onto printed circuit boards (PCBs). Such companies participate significantly in the PCB assembly process, which involves converting bare boards into functioning circuits that give life to all forms of modern electronics.

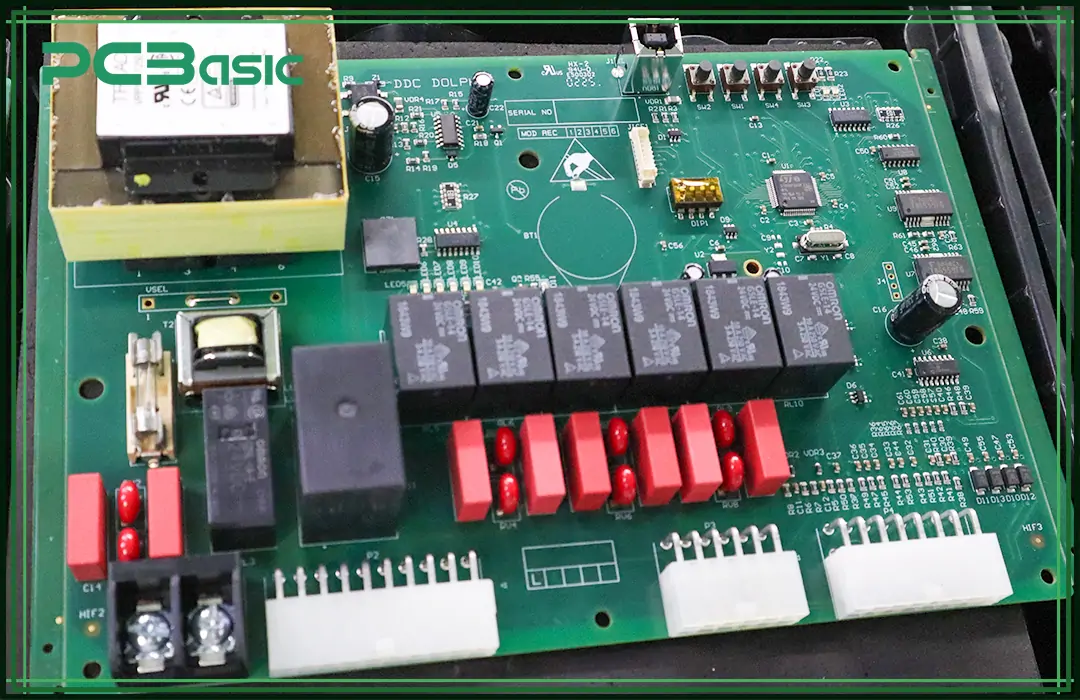

A professional PCB assembly manufacturer typically offers an array of PCB assembly services for industries varying from consumer electronics and automotive to medical devices, aerospace, and telecommunications.

From prototype PCB assembly to turnkey PCB assembly- providing everything from component sourcing, assembly, quality inspection, and testing companies ensures that each assembly and circuit board passes stringent performance and reliability tests.

The importance of cooperating with an experienced PCB assembler cannot be underestimated. Quality PCB manufacturing and assembly are the guarantees for better product reliability, reduced chances of failure, and timely introduction in the marketplace.

A lot of companies, especially startups and product designers, depend upon PCBA China companies like PCBasics, which is famed for its low-cost SMT PCB assembly and high quality.

A professional PCB assembler — referring to companies that specialize in PCB assembly services — brings a wealth of technical skills and industry expertise to the table. Successful PCB assembly businesses must possess the greatest range of competencies to manufacture a reliable, high-performance electronic product.

PCB assemblers must be experts in multiple kinds of PCB assemblies like SMT PCB assembly (Surface Mount Technology) and THT (Through-Hole Technology). They know how to handle delicate components, apply precise soldering techniques, and optimize the PCB assembly process that ensures strong, reliable connections.

From the proper solder paste to high-quality components, PCB assemblers should be experts in materials science. It is more prominent in prototype PCB assembly because the choice of the material will directly affect the performance and life span of the final product.

Leading PCB manufacturers apply stringent quality control to every level of the process. This consists of automated optical inspection (AOI), X-ray inspection of hidden joints, and then functional testing to make sure that each assembled board is working perfectly.

Experienced PCB assemblers closely work with product designers to ensure that PCB designs are made for cost-effective, fast, and smooth manufacturing in this design for manufacturing (DFM). Avoiding huge redesigns saves time in production, which is most applicable for turnkey PCB assembly projects.

A reliable PCB assembler must have good supply chain management, the way PCBasics does. From sourcing components from reputable suppliers to delivering products to customers, PCB manufacturers need to have strong supply management. Good supply chain management protects production, especially for complex or high-volume orders.

Printed circuit board assemblers are important players in delivering quality and ensuring the reliability of electronic products. The accuracy with which they position and solder components to printed circuit boards impacts the performance of everything from consumer electronics to industrial gear. If a circuit board assembler lacks skills, then there will be no more revolution in this field. So, they are the primary handlers of this field.

In ensuring precise placement of components on boards and soldering onto the PCB, a skilled assembler employs state-of-the-art machinery such as pick-and-place equipment, reflow ovens, and AOI (Automated Optical Inspection) systems. Any misplacement, cold solder joint, or contamination during the PCB assembly can lead to a product failing in the field.

Any good PCB assembly service will help source authentic and high-quality components. Poor quality or counterfeit parts will largely shorten product lifespan, so it is equally important to source components as a pillar in quality PCB manufacturing and assembly.

Exclusive circuit board assembly service providers follow the set standards of quality control for visual inspections and electrical and functional testing. Therefore, all assembled boards are tested to have the intended voltage and current parameters before hitting the shop floor. Hence diminishing costly product recalls or customer complaints.

The longer a product survives can depend on the quality of PCB assembly. High assembly quality translates into good thermal, signal, and mechanical durability, all of which greatly contribute to a product's lifetime in real-world conditions.

PCBasic is an assembler at the top of quality designs, with world-class inspection and testing to ensure a product is perfect.

PCBasic is undoubtedly an established name in the PCB assembly service market. This PCB assembler offers an end-to-end solution. PCB assembly services, sourcing of components, and final testing - PCBasic offers an entire streamlined process where quality meets efficiency for every project.

PCBasic offers a comprehensive range of PCB fabrication and assembly services dedicated to the needs of modern electronics, making them stand out from the printed circuit board assembly companies. Whether it is a state-of-the-art smartphone or an IoT gadget that you can seamlessly swipe prices on Amazon for, we are adept at using sophisticated techniques such as surface mount technology (SMT) and through-hole technology (THT).

Advanced capabilities in SMT PCB assembly and through-hole assembly empower PCBasic to handle a vast range of designs from compact consumer devices to complex industrial control systems. If you're looking for a prototype PCB assembly to test a product at the early stage or turnkey PCB assembly for mass production, it can be handled with ease.

All along the PCB assembly process at PCBasic, quality is a prominent factor. Each board is subjected to stringent inspection from Automated Optical Inspection (AOI) to functional testing, to ensure that every assembled product meets the highest standards for performance and reliability.

PCBasic offers flexible manufacturing capabilities to startups, small businesses, and large enterprises. Whether you need low-volume prototype PCB assembly to test a new design or assembly services for high-volume circuit boards for mass production, PCBasic will adjust its services to meet your needs.

Leveraging strong relationships with PCBA China suppliers, PCBasic offers competitive pricing on components without compromising quality. This makes it an ideal partner for businesses seeking cost-effective PCB assembly services with a global supply chain advantage.

Whether your focus is on a new product launch or optimizing an existing design, PCBasic has the technical capability and manufacturing excellence to make that success happen. Our professionals ensure the installation of every part will be precisely based on the highest industrial standards. Our passion for excellence drives us to breathe life into your electronic designs by facilitating flawless functioning.

In an industry as fast-paced as electronics, PCB assemblers become crucial in converting innovative designs into reliable and functioning products. These companies are backbone support for modern electronics manufacturing — taking charge of complex PCB assembly processes, ensuring stringent quality control, and sourcing the best quality components.

Complying with a competent PCB assembly manufacturer ensures that every PCB assembly, whether it is a prototype or a high-volume turnkey assembly, meets the predominant standards of performance and reliability.

Streamlined production with companies like PCBasic offering one-stop PCB manufacturing and assembly solutions, reduced time-to-market, and increased competitiveness — these become important for any business.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.