Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBasic's Professional Through-Hole Prototype PCB Assembly Services

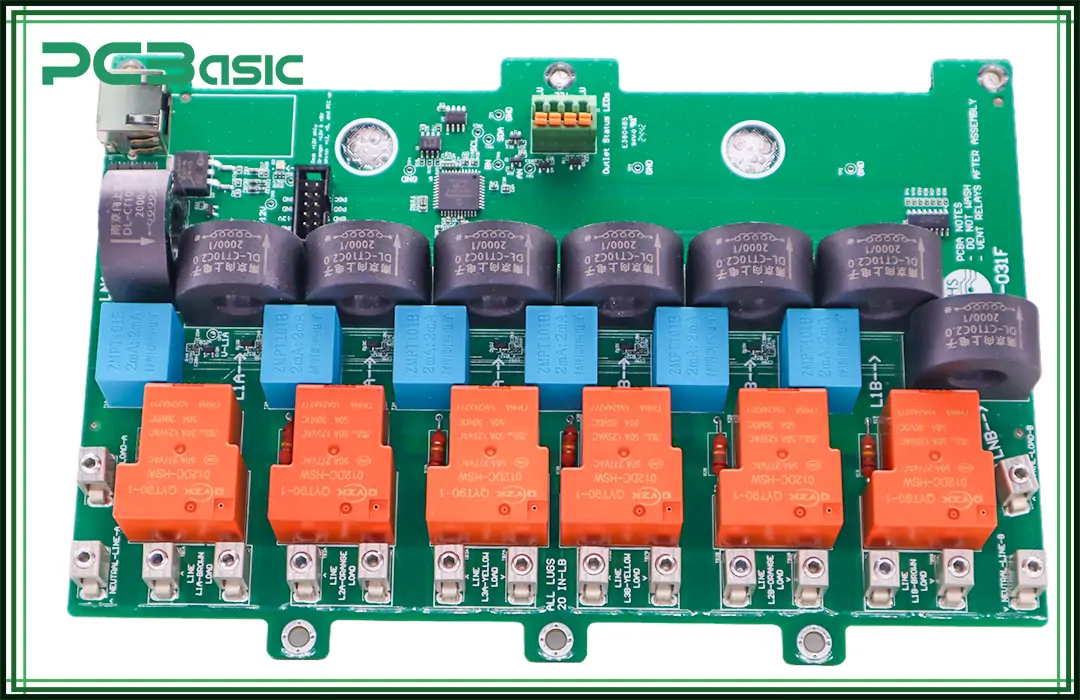

Through-hole PCB assembly remains one of the indispensable processes in PCB assembly manufacturing, with extremely high reliability and durability in high-performance applications.

PCBasic specializes in a wide range of PCB prototype assemblies, including through-hole PCB assembly services, offering hand soldering, selective wave soldering and advanced assembly equipment. With more than 10 years of PCB design and assembly experience and as a trusted PCB assembler, PCBasic provides high-quality PCB solutions to various industries.

Through-Hole Technology (THT) is a traditional PCB assembly method that is widely used in the electronics manufacturing industry. Its core feature is to insert through-hole components with metal pins into pre-drilled holes on PCBs and fix them by thru-hole soldering.

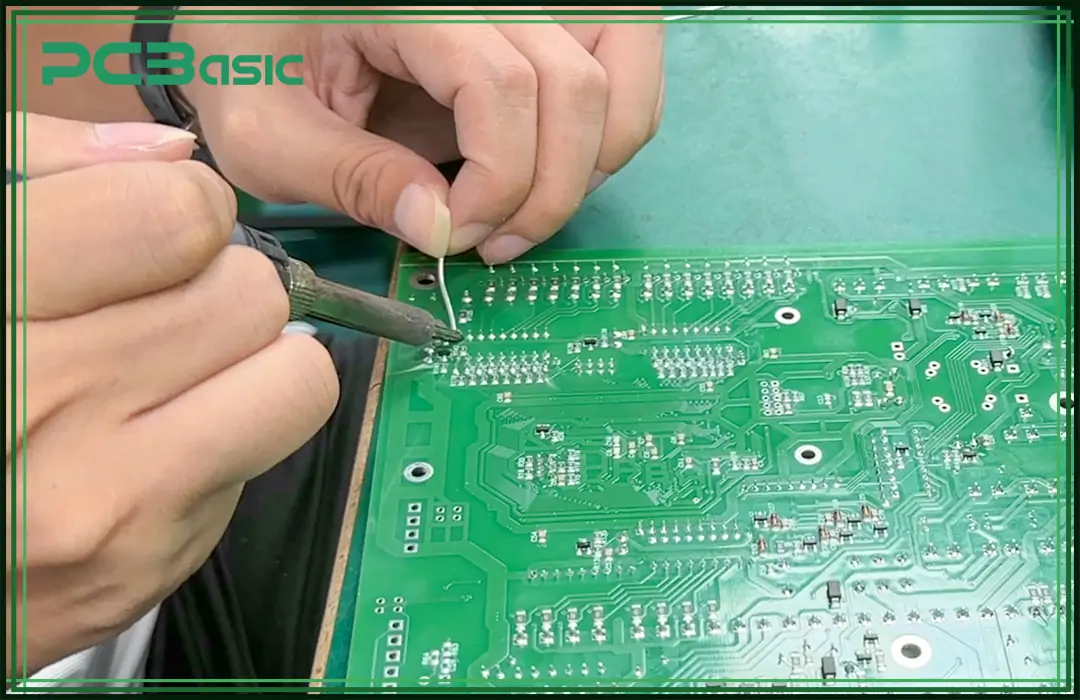

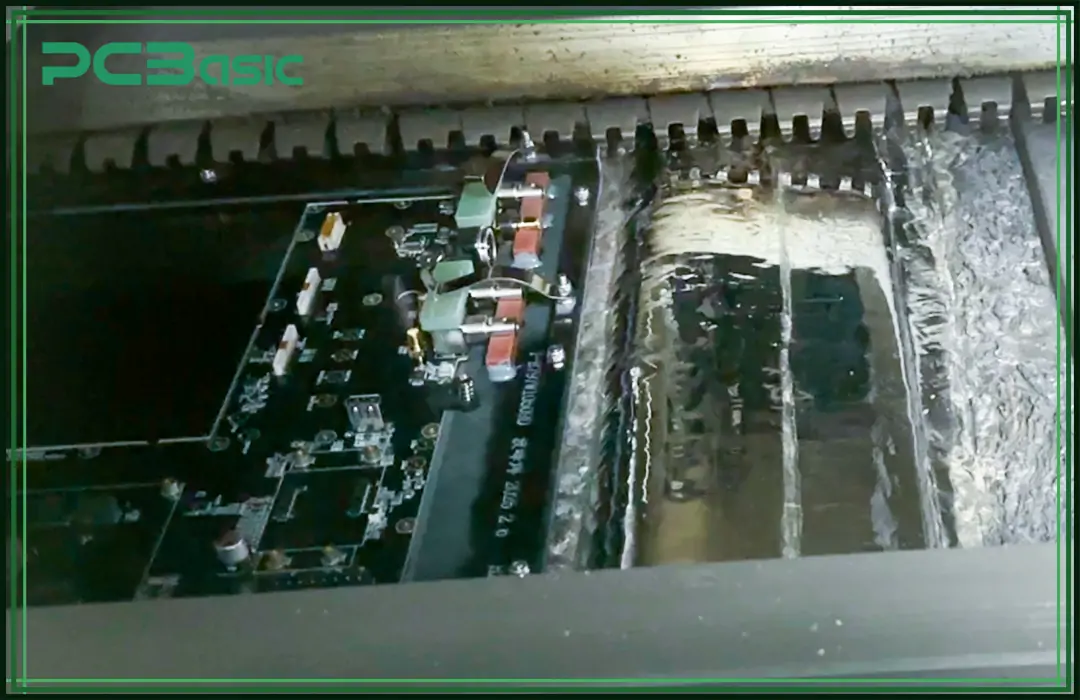

During the soldering process, these metal pins are inserted through PCBs and soldered on the back so that they are firmly connected to the conductive pads. Soldering can be done by hand soldering or wave soldering, or using a selective soldering process.

The pins of through-hole components are inserted into the PCB directly and form a solid connection to the pad. The solder joints can withstand large physical stresses and high temperature. Therefore, the through-hole technology performs better in high-reliability, high-strength applications. For example, in aerospace, military equipment, industrial control systems and other applications requiring durability, shock resistance and strong current carrying capacity, THT is still an irreplaceable choice.

Component Placement

Through-hole components are accurately inserted into pre-drilled holes on printed circuit boards by manual or automatic instrumentation. To ensure proper electrical connections and reliability, all components must be precisely positioned according to the PCB design. In addition, the pin length, orientation, and spacing must comply with the design specifications.

Soldering Process

Through-hole soldering usually uses three main methods:

1. Hand Soldering - Suitable for small batch production, prototype PCB assembly, or circuit boards requiring manual adjustment. Engineers use a soldering iron and a soldering wire to solder the components one by one to ensure a strong connection.

2. Wave Soldering - Suitable for mass production. The circuit board is moved through a conveyor belt and passes through a molten solder crest so that all through-hole solder joints are soldered at once.

3. Selective Soldering - Suitable for mixed PCB assembly; that is, the PCB contains both through-hole components and surface mount components (SMT). The process uses precisely controlled solder nozzles to solder only specific through-hole components, avoiding impact on the SMT components.

Inspection and Testing

After soldering, rigorous quality testing of the circuit board is required to ensure the reliability and electrical performance of all solder joints:

1. Automated Optical Inspection (AOI) - The PCB is automatically scanned by a high-resolution camera to detect solder joints, component directions and solder integrity. This is to ensure that there are no defects such as missing solder joints, misaligned components, solder bridges, or cold solder joints.

2. X-Ray Inspection – It is used to inspect internal solder connections, especially for high-density PCB designs and complex multi-layer PCBs.

3. Functional Testing (FCT) - Simulate the actual working state of the circuit board through a special test fixture or probe to verify whether it can operate normally according to the design requirements.

Surface Mount Technology (SMT) is a modern PCB assembly technology. It solders surface-mount components directly to the PCB surface without drilling and mounting as with through-hole technology. This technology greatly improves the integration, production efficiency and miniaturization of electronic products. SMT is currently the most widely used PCB assembly process.

|

Feature |

Through-Hole Technology |

Surface Mount Technology (SMT) |

|

Soldering Method |

Thru-hole soldering, hand soldering, and selective soldering process |

Reflow soldering |

|

Mechanical Strength |

High |

Lower than THT |

|

Component Size |

Larger |

Smaller |

|

Durability |

Stronger |

Less robust in high-stress environments |

|

Cost |

Higher for mass production |

Cost-effective for small devices |

While surface mount technology is preferred for compact devices, through-hole PCB assembly is superior in applications requiring robust and long-lasting performance.

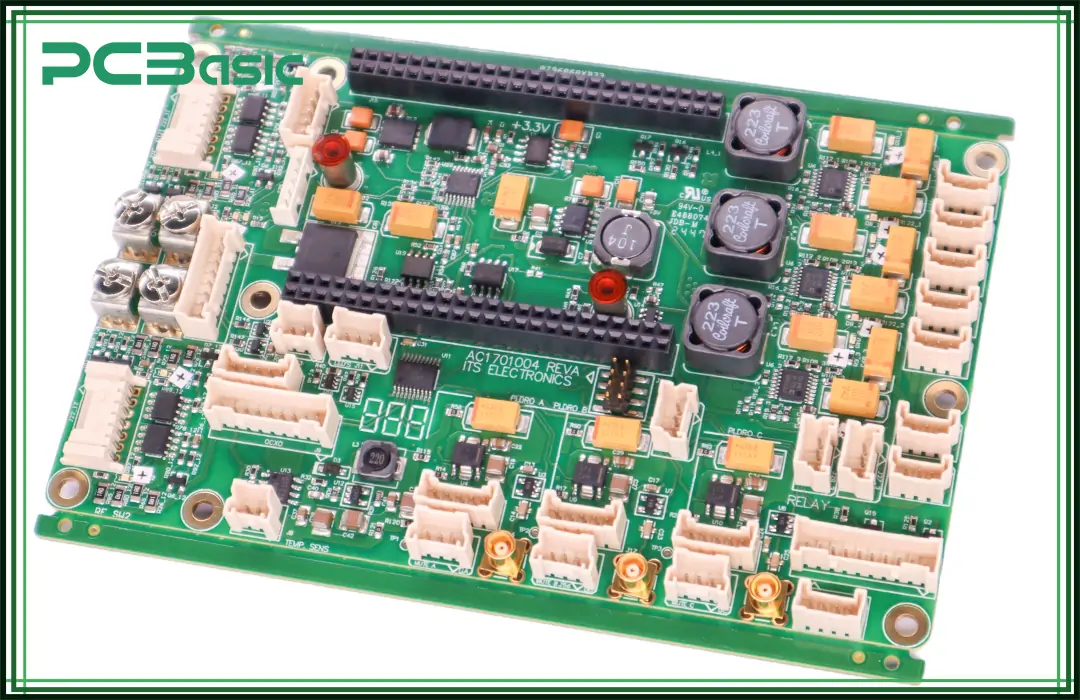

PCBasic offers professional through-hole PCB assembly services, catering to both small-batch prototyping and large-scale manufacturing. Its turnkey PCB assembly process ensures seamless handling of through-hole components, from procurement to final assembly.

Key Features of Our Through-Hole Assembly Service

Multiple Soldering Methods – PCBasic offers hand soldering, wave soldering, and selective soldering

processes.

Advanced Assembly Equipment – Its manufacturing facilities are equipped with cutting-edge machinery for PCB assembly manufacturing.

Prototype PCB Assembly – Fast turnaround for R&D and small-scale production.

Full PCB Design and Assembly Support – It can assist in PCB design and assembly, ensuring optimized layouts for manufacturability.

Turnkey PCB Assembly Solutions – PCBasic manages everything from component sourcing to final delivery.

Additionally, PCBasic offers comprehensive through-hole PCB assembly services, including:

• Prototype PCB assembly

• Small to medium-volume production

• Turnkey PCB assembly

• PCB design and assembly consultation

• Component sourcing and management

• Quality control and testing

Its state-of-the-art assembly equipment and experienced technicians ensure high-quality through-hole PCB assembly for your prototypes and production runs.

As the industry's leading PCB design and assembly service manufacturer, PCBasic has more than 10 years of industry experience. At the same time, it has advanced manufacturing capabilities, strict quality standards and efficient one-stop service. PCBasic can provide customers with high-quality, stable and reliable through-hole PCB assembly solutions.

1. Decades of Experience

2. Advanced Manufacturing Capabilities

3. High-Quality Assurance

4. Efficient and Cost-Effective Services

PCBasic's professional through-hole prototype PCB assembly services combine years of expertise, cutting-edge technology, and a commitment to quality. Whether you need through-hole soldering for a prototype or full-scale PCB assembly manufacturing, its team is equipped to handle your project with precision and care. Trust PCBasic for all your through-hole PCB assembly needs and experience the difference that true expertise makes in electronics manufacturing.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.