Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Top Surface Mount PCB Assembly Manufacturers in China

China is one of the largest producers of SMT and PCB assemblies in the world, reputed for high quality production, advanced technology, product assembly and cheaper alternatives. Companies that specialize in this field include Foxconn, SCC and PCBasic. Manufacturers with great acclaim in testing and assembly of SMT, dwell in this place, providing component sourcing and prototyping with an expertise core in PCB mounting. They meet international standards like ISO 9001 and IPC, and are equipped with state-of-the-art facilities to serve a variety of industries, including consumer electronics, automotive, medical devices, and telecommunications.

SMT indeed has revolutionized the PCB manufacturing sector, permitting the manufacture of really smaller PCBs with better quality and lower costs. Instead of placing the component down through the whole board, SMT simply places the component over the surface of the board, really augmenting performance and quality.

The manufacturing process by SMT enhances productivity, reduces costs, and enhances the quality of digital products. The technique enjoys a wide variety of applications within the sector of consumer electronics, telecommunications, automotive, and medical devices; thereby, SMT is a core technology in electronics manufacturing, these days.

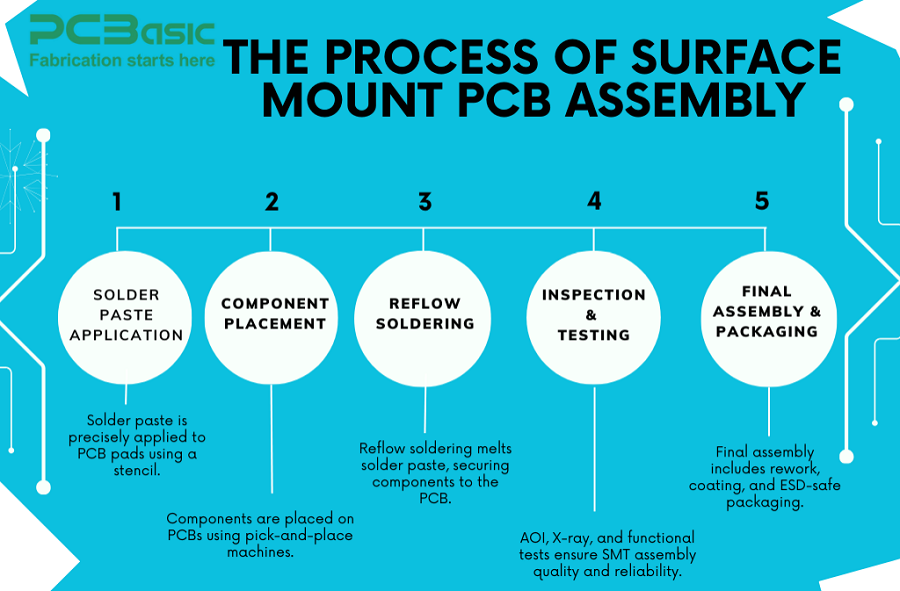

There are numerous steps in this manner to ensure the reliability and capability of electronic devices are met. Let's observe the critical processes:

1. Solder Paste Printing

A stencil is used to apply solder paste to the predefined locations on the PCB, where additives could be positioned into the role. This paste consists of solder particles with flux which are intended to bond successfully.

After the solder paste application, the board moves to component placement, in which automatic pick and place machines roll floor-mount gadgets (SMDs) onto the PCB. These high-pace machines use advanced vision structures for alignment and hire vacuum suction gear for touchy parts like microchips and BGAs to prevent damage.

3. Reflow Soldering

In this step, the PCB is put in a reflow oven. Because the soldering paste's melting temperature is lower than the soldering temperature, the additives are melted into the region at the PCB. The solder profile of the oven is designed in a manner that the additives aren't damaged at the same time as achieving the specified temperature.

Post soldering, the board, to check for any alignment, soldering mistakes, or missing parts, Automatic Optical Inspection (AOI), and X-ray inspection for more complicated boards are used.

After the test, the unit is placed in the final housing and packed for shipment, or more and more units is entered into the system.

That application's streamlined process guarantees that surface-mount PCB assembly is manufactured with utmost precision, efficiency, and reliability, making it one among the most recommended options for modern electronics applications.

PCB manufacturing is one of the best in the world out of China. High-quality and cost-effective. Here are just six of the top SMT PCB assembly China-based manufacturers:

Hon Hai Precision Industry Co. is also known as Foxconn and it is one of the biggest electronics manufacturers and contract producers in the world based in Taiwan. The agency which was established in 1974 has its plants producing a wide variety of electronic components, from published circuit boards (PCBs), semiconductors, to customer electronics. Foxconn has an important role in the international supply chain, producing products for major brands like Apple, Sony, Microsoft, and Tesla. Its knowledge spans several industries including consumer electronics, automotive, medical devices, and telecommunications.

With a strong international reach, Foxconn has advanced production facilities in China, India, the United States, Mexico, and Europe and uses modern technologies such as surface-mounted technology (SMT) and printed circuit board (PCB) assembly to produce high-volume and excellent products. After becoming known due to its performance and innovation, Foxconn continues to set off changes in electronics production through advances in automation and intelligent factory solutions.

Established in 1984, Shannan Circuits Co., Ltd. (SCC) is a leading manufacturer of PCBs out of Shenzhen in Guangdong, China. One of the five largest global PCB producers, they specialize in high-speed, high-capacity, RF and microwave, thermal management, and miniaturization solutions. Their services include PCB design and fabrication, assembly and testing for various applications from telecommunications and automotive to medical and industrial applications.

With manufacturing facilities in Shenzhen, Wuxi, and Nantong, SCC maintains a strong global presence, underscored by its subsidiaries in North America and research and development sites in Europe. Their commitment to innovation and quality positioned them well for strategic partnerships with leading manufacturers in communications and medical equipment worldwide.

PCBasic has emerged as a leading PCB and PCBA manufacturer, based out of Shenzhen, China, and recognized for a complete package of comprehensive service prior to prototyping and during mass production. The company was established in 2011, and has come a long way in operating for over a decade within the electronics manufacturing industry.

PCBasic excels in the delivery of top-notch printed circuit boards in shorter turnaround times to inexpensive pricing to cater to various industries like consumer electronics, automotive, telecommunications, and medical devices. They provide services inclusive of PCB design, fabrication, assembly, and testing - all this finishing up with an excellent process. With certifications such as ISO9001, IATF16949, and ISO13485, PCBasic meets certain high-tech standards, rendering it a venerable ally for myriad software requisites. The company has equipped state-of-the-art facilities that offer omnidirectional services through the use of advanced apparatus, hence achieving extremely high productivity with stringent quality control standards set up. PCBasic's commitment to excellence and customer satisfaction sees it become a reliable company in PCB manufacturing.

|

Manufacturer |

PCB Fabrication |

PCB Assembly |

Prototyping |

Turnkey Services |

Component Sourcing |

Industries Served |

|

FOXCONN |

Yes |

Yes |

Limited |

Yes |

Yes |

Consumer Electronics, Automotive, Medical, Telecommunications |

|

SCC |

Yes |

Yes |

Yes |

Yes |

Yes |

Automotive, Medical, Telecommunications |

|

PCBasics |

Yes |

Yes |

Yes |

Yes |

Yes |

Industrial, Consumer Electronics, Aerospace |

This comparison provides a clear overview of each manufacturer's strengths, helping businesses choose the best partner for their PCB assembly needs.

China's dominance in PCB manufacturing is due to several key advantages:

1. Cost-Effectiveness

The choice of PCB assembly to China provides cost advantage for global businesses. Sourcing from China, therefore, companies will be in a position to reduce their production cost owing to the high standard services provided affordably by Chinese manufacturers.

2. Advanced Technology

China constantly invests in technology and high-end PCB assembly equipment. Some Chinese producers of PCBs and other electronic components claim that their factories are equipped with very advanced and even better than those in the West.

3. Comprehensive Services

Many Chinese manufacturers offer end-to-end solutions, covering everything from PCB design to final assembly. These solutions often include component sourcing, prototyping, and testing services to ensure quality and efficiency. This one-stop-shop approach makes life easy for businesses with the least waste of time and effort.

4. High-Quality Standards

Good PCB assemblage techniques that conform to strict quality control measures. Noteworthy inspection processes with prominent applications include AOI, X-ray, and functional testing for early detection of defects, while lofty benchmarks are maintained. Compliance by manufacturers with international certifications such as ISO and IPC guarantees constancy and quality.

5. Customization & Flexibility

Chinese PCB manufacturers offer customization and flexibility to meet diverse project needs. They adapt to specific designs, materials, and production volumes, ensuring tailored solutions. This versatility helps businesses achieve unique product specifications efficiently.

6. Global Shipping & Support

Chinese PCB manufacturers provide efficient global shipping with streamlined logistics to ensure timely delivery. Their dedicated customer support assists international clients with orders, technical issues, and customization needs. This reliability enhances supply chain efficiency and customer satisfaction.

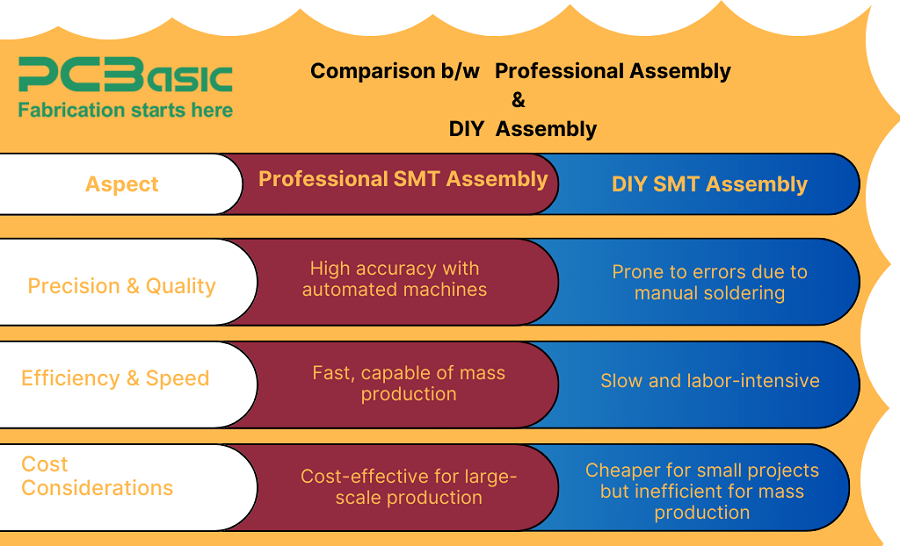

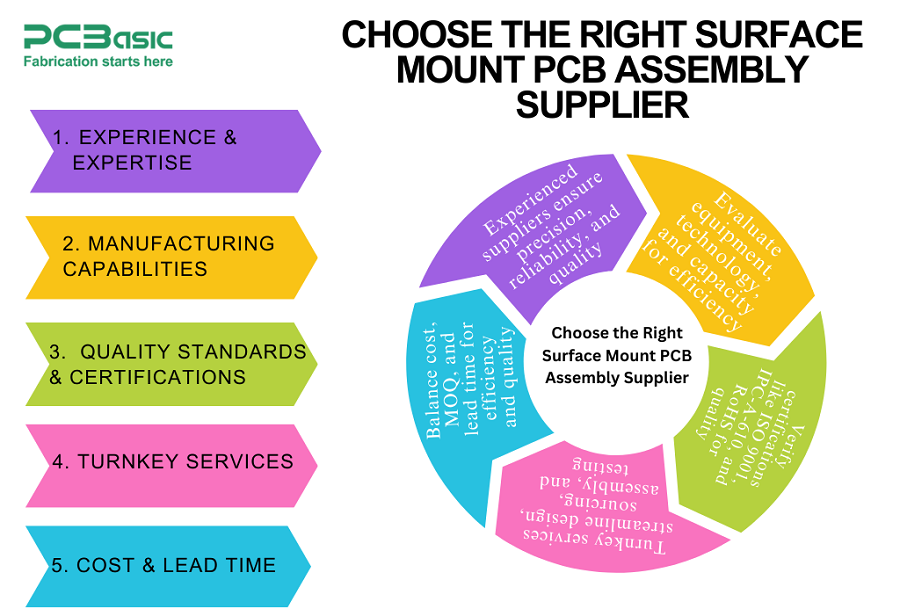

Choosing the supplier for SMT PCB assembly wisely assures quality, economical, and efficient production. Several major parameters are to be kept in mind:

A supplier in your industry will therefore know the specific needs and intricacies of your field. An experienced supplier will have become skillful at his trade, thus ensuring quality and consistency. They can handle complex PCB designs and components, reducing errors and overall quality.

Ensure to check the supplier's equipment or facilities, technologies, and manufacturing capabilities to see if they can fulfill your project's requirements. To confirm, look for reflow ovens, AOI/X-ray inspection systems, and advanced pick-and-place machines. A supplier with the right tools can manage small prototype runs and large-volume production.

Good factories will have strict quality control to ensure that the printed circuit boards they manufacture are reliable. Look for certifications such as ISO 9001, IPC-A-610, and RoHS compliance, which means they adhere to international manufacturing and environmental standards. Together, these certifications mean you can expect certain levels of production quality and safety from your supplier.

A full-service company provides a wide range of services, including full-cycle solutions, PCB layout design, sourcing of components, assembly, and testing, which makes the process easier for all parties involved. With turnkey services, time and effort are reduced by not having to coordinate work with several vendors. This results in a smoother operating procedure, with no delays or compatibility issues.

Selecting a supplier requires balancing cost with the delivery of the product. Pricing structure, minimum order quantity (MOQ), and lead time are very important factors to examine so you can find a supplier fitting your requirements without incurring a cost to quality. Reasonable suppliers will have a competitive pricing scheme very well integrated into production.

By considering these you can find a trusted SMT PCB assembly supplier that matches your project requirements and smooth collaboration.

Known as the leader in Surface Mount PCB Assembly, China is providing some of the best quality boards at reasonable cost across all industries. The correct manufacturer can provide your business with advanced technology, scalable production, and excellent customer support. Most Chinese SMT PCB assembly manufacturers are capable and equipped to meet your requirements, no matter how small or large the run is.

China has evolved to become a global leader in Surface Mount PCB Assembly. The uniqueness and quality of their product cater to an array of industries at competitive prices. The poor manufacturing infrastructure coupled with a not-so-sought-last-technology and an undisciplined workforce makes China the most sought-after choice for PCB Assembly services.

Choosing the right manufacturers provides the kind of benefits you can't imagine: allocation to advanced technology means optimized production processes, improved efficiency, and good reliability of the final product you get. The manufacturers are equally comfortable doing a small run of quick prototyping and completing orders in extended series, hence suited to companies ranging from startups to big corporates.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.