Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed Shenzhen PCBA manufacturer

Ru

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What is the SMT Meaning? Process, Features and Applications!

The meaning of SMT is as simple as placing small components such as the resistor and chips on the boards. What is SMT? SMT aids in making objects such as phones to be faster and even smaller. This blog will discuss how it works in detail and why SMT improves the devices.

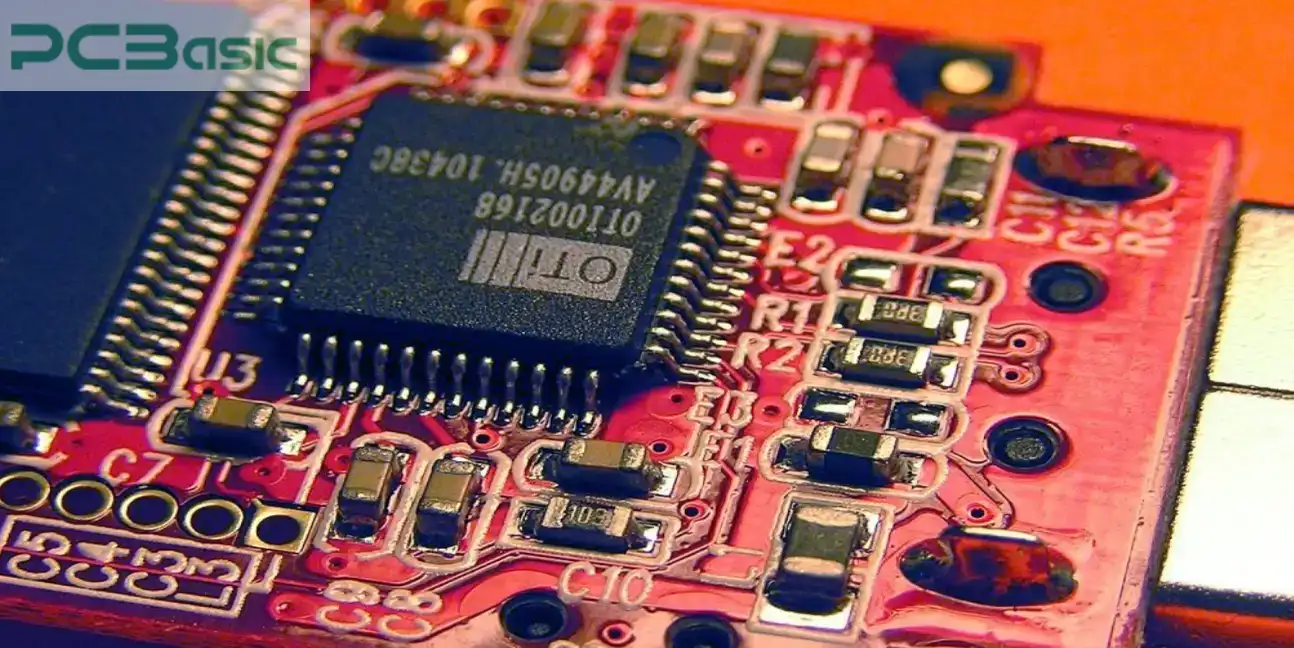

What does SMT mean? SMT is an acronym that stands for Surface Mount Technology. SMT assists in arranging small elements like resistors and capacitors for their placement on boards. These parts are placed on top by the machines known as the pick-and-place machines.

First of all, let's define the meaning of the abbreviation SMT. It stands for speed. SMT makes things faster! The machines work at an incredibly fast pace and can place thousands of parts within one hour.

What does SMT stand for? It is applied to phones; they become smaller, thinner, and more durable as a result of this component. For instance, the space between parts is 1.27 mm. SMT employs specific elements such as ICs and SMDs. What does SMT stand for? That is how gadgets work faster, such as Wi-Fi at 2.4 GHz. The boards are quite stiff with few distortions. This makes SMT important. SMT also reduces material by utilizing little deposits of solder.

About PCBasic: PCBasic is a leading China PCB Assembly Company and trusted PCB Assembly Manufacturer, offering end-to-end PCB Assembly Services for various industries. With advanced SMT lines, strict quality control, and fast turnaround, PCBasic ensures reliable performance for every board delivered.

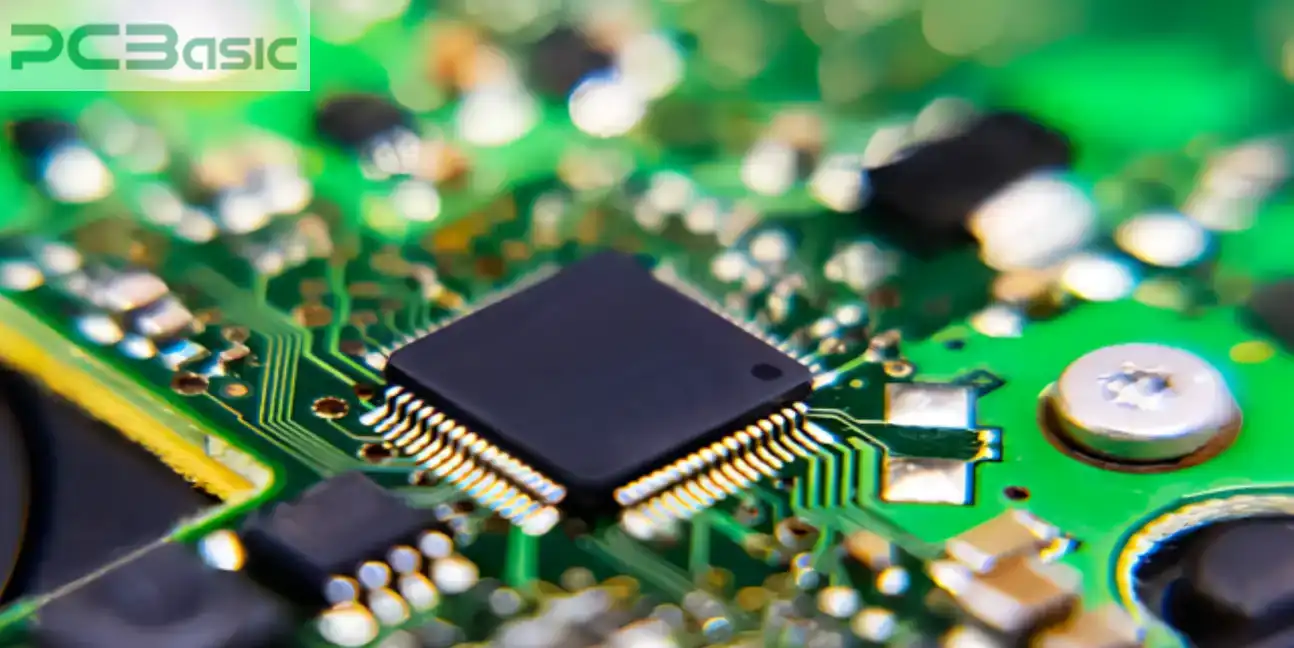

SMT stands for Surface Mount Technology. It starts in the 1960s. This method helps place small parts like resistors and capacitors on PCBs (Printed Circuit Boards). SMT uses tiny resistors like 0402 or 0603. That saves space on the board. This method uses robots to install parts like LEDs, diodes, and Integrated Circuits. They connect the parts well and work fast.

It puts solder paste on pads and heats up to 250°C to melt the paste. SMT meaning also includes making things smaller and faster. Engineers use BGA (Ball Grid Arrays) with many pins. The parts don't need wires like older methods. SMT assembly can make devices like phones very small and efficient.

The method makes devices better. They don't use much power and don't get hot. SMT lines work in minutes, sometimes even seconds, to place hundreds of parts. SMT keeps things organized and helps everything run smoothly with fewer mistakes in the PCB assembly.

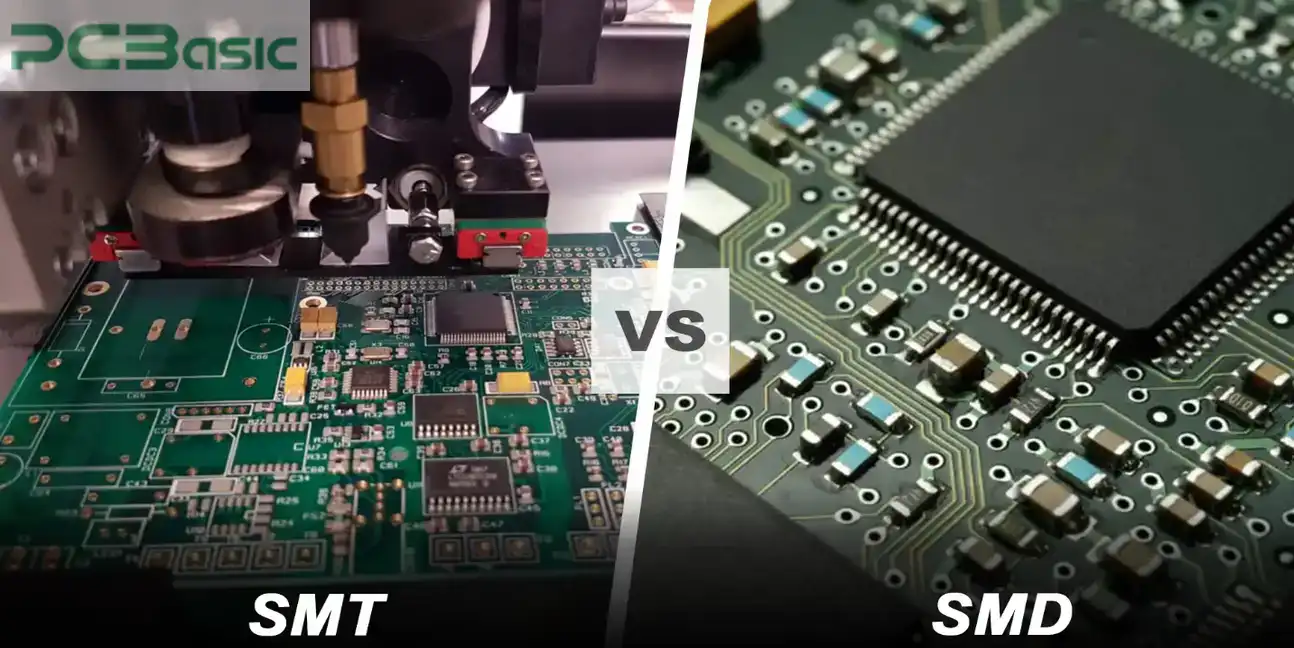

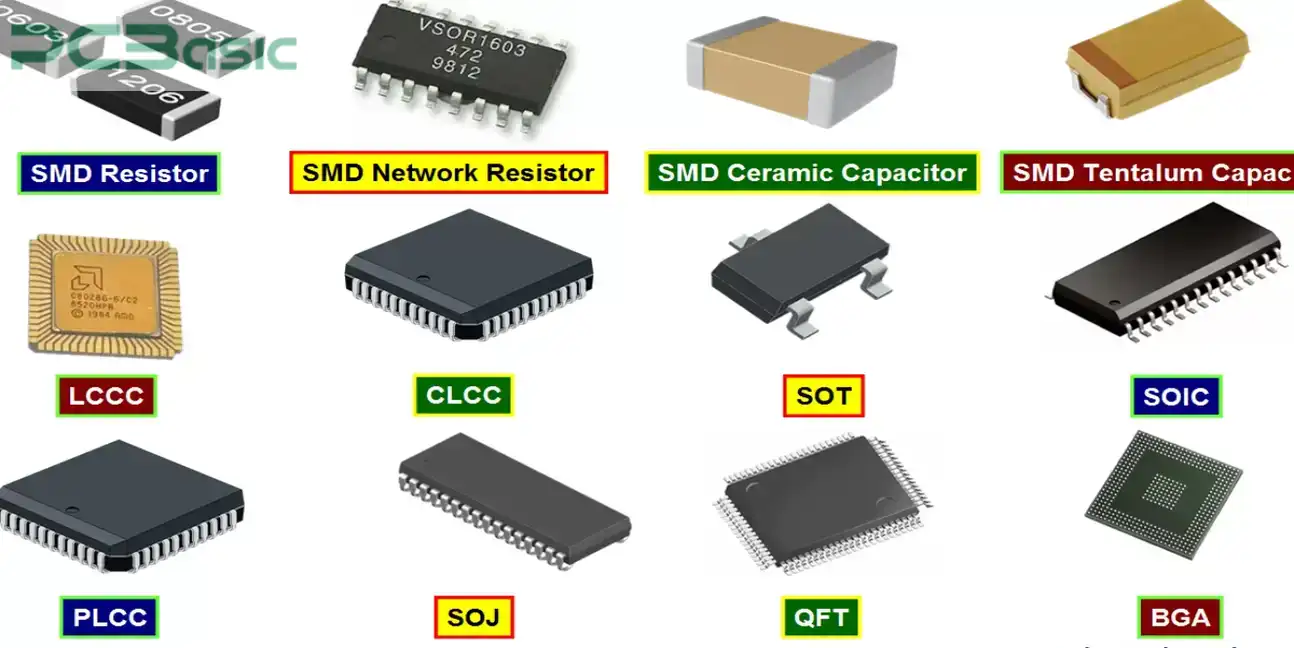

SMT stands for Surface Mount Technology. It mounts SMD components on a circuit board. SMD, meaning Surface-Mounted Device, refers to tiny components used in electronic assemblies.

These SMD components are small in size. For instance, there are resistors that are 1.6mm in size and capacitors that are 2mm in size. They assist devices such as phones to perform their operations faster. It is interesting to note that SMT can handle over 1,000 parts on one board!

The board is known as a PCB. It supports SMD components and can hold them without any wire connection. It can get up to 240°C for the heat needed to solder. This makes SMD components stick tight. Thus, devices remain compact and portable. As gadgets with 1GHz speed, they perform well making phones and tablets much faster.

Related blog: Motherboard Water Damage: Can a Wet Motherboard Get Repaired

Just as in SMT manufacturing, small dots of paste are put on boards. These dots ensure that several parts adjoin or hold together as desired, depending on their required form. The paste is sticky, just like the paste that you use in holding the stick on the paper, but this helps electricity to flow.

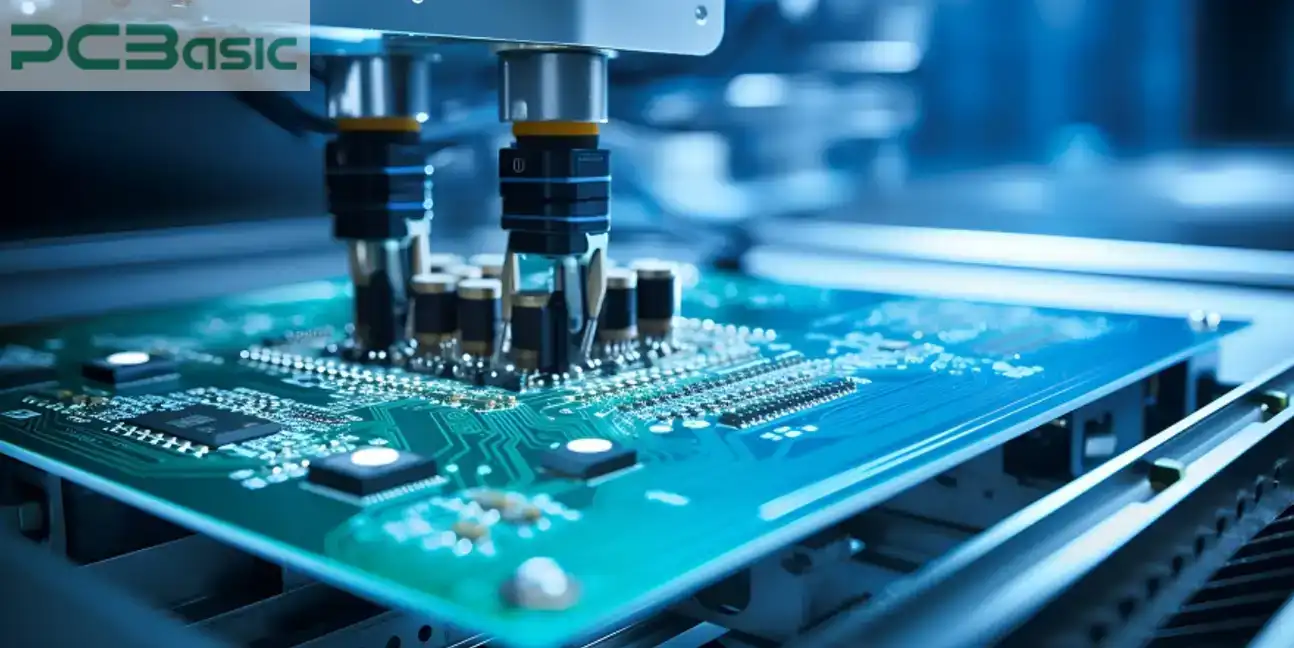

The paste is then applied to the board after using a SMT stencil. The SMT process helps to place the parts accurately. This helps to locate parts where they belong. They employ a specific machine to accomplish this in a rather swift manner. It ensures that the paste is spread all over the board.

The small paste dots are useful when joining components such as resistors and chips. That assists the board to perform well when aggression rises later on.

SMT manufacturing is the process of placing parts on boards. Every commodity, be it resistors or chips, has to be situated in the proper place within the circuit board.

The SMT process ensures precise placement of all parts on the board. The solder uses a machine to pick and place the SMD parts in the right position on the board. This machine is very fast and places all parts in the correct locations. The parts adhere to the paste on the board.

It stabilizes them. Thus, the board is ready to undertake the next action. It has to be in harmony to such an extent that every element must be in a correct place and function them properly.

Heated is the board in reflow soldering. In SMT manufacturing, the board with parts is placed in a hot oven so that soldering can occur. This is because when it is hot, the paste melts and glues the parts into position on the board. This assists the functioning of the board.

They manage the temperatures well to ensure that nothing catches fire. It ensures all parts remain combined. In this way, the board can perform its functions as required by the management of corporate organizations. The parts and paste are solidified, and the board is rewritable after being lowered to room temperature.

|

Process |

Purpose |

Tools |

Temperature |

Speed |

Automation |

Accuracy |

|

Solder Paste Application |

Apply solder paste to PCB |

Stencil Printer |

N/A |

High Precision |

Semi-Automated |

0.1 mm |

|

Component Placement |

Place Components on PCB |

Pick and Place Machine |

Room Temperature |

High-Speed Placement |

Fully Automated |

±0.05 mm |

|

Reflow Soldering |

Melt Solder to Bond Components |

Reflow Oven |

150°C - 260°C |

Controlled Heating |

Fully Automated |

Precise Heating Zones |

SMT saves money. These tend to employ fewer people while incorporating more machinery into the work process. This reduces the cost by half, which is a significant move towards efficiency. Manufacturing machinery produces 80,000 components per hour.

SMT is defined as an implication of reduced use of material by 30%. The solder is 0.05 mm thick. This makes it suitable for making many gadgets fast. This means more moving parts and less repairing, which are two critical aspects of any appliance. They maintain production affordable and quick.

SMT gives faster signals. The parts move signals instantly, up to 10 GHz. That means devices work fast, just like computers work in a given system. SMT meaning also involves the ability to handle more power with 1.5 W/mm². The sub-parts make signals better shortened.

This keeps devices cool. They are long-lasting since they do not heat up, and this reduces the lifetime of the other apparatuses. The board navigates power nicely, ensuring that phones and routers operate optimally.

SMT helps to make devices compact and lighter in weight. The board area has been reduced to 70%. The meaning of SMT also includes the use of miniature components like the 01005 capacitors, etc. That assists install more elements per unit area. It also leads to phones and tablets becoming thinner.

The smaller parts are tried to keep strong and do not get a break. They stretch the time taken for a device to be retired. SMT is used for keeping gadgets lightweight, such as, smart watches and miniature tablets.

SMT works towards speeding up the process of constructing gadgets. Machines assembled 70 parts per second. Which makes phones and tablets fast to build. SMT's meaning also extends to the application of heat to bond parts onto fast, which increases the rate of production by 60%.

It enables factories to produce millions of phones and tablets. Many retain on making parts in the same manner with no errors at all. That means devices work well and are made quickly.

It is also important to understand that SMT can work with any sort of part. SMT meaning also encompasses the use of chips with numerous pins such as FPGAs. These have up to 1,000 pins. They assist gadgets to function optimally. It can also handle the placement of odd-shaped parts like coils.

This ensures that the board categorizes different parts and operates efficiently. That helps build smart gadgets. They take many parts and put them together and create all sorts of cool new items.

Another reason for embracing SMT is that the parts used are small, which poses a threat of damaging them easily. It requires caution when it is being used. SMT meaning also encompasses the use of extremely small sizes, such as the 0201 capacitors. These parts are fragile.

Store at room temperature and do not use pads that are 0.2mm thick. If they are too hot, they can crack. This can cause devices to cease to function. They require special tools for putting them where they are needed. This makes it difficult to see the small parts of an object or a picture. This makes it difficult to verify that they are good.

SMT is difficult to fix. Apart from the above facts, SMT is also difficult to fix since its net profit margin is very low. SMT's meaning also extends to very small parts such as 01005, which is difficult to work with.

And that makes it difficult to repair parts. It needs fixing and requires certain machines to accomplish the task. The parts are adjacent to each other, spaced only 0.5 mm apart. This means that in order for tools to be effective, they need to be extremely small. It is not easy to fix by hand.

SMT cannot support large power currents. SMT also embraces small components, such as 0805 resistors. These can handle only 0.125 W. That makes them less good for big power devices.

They get easily heated with a current above 2A. This damages the board. This is why for smaller power devices SMT is slightly more effective than its counterpart, through-hole mounting. It means that they are appropriate for devices such as phones but not big machines.

Technologically advanced SMT machines are expensive. SMT means also involves using robots and ovens to produce the boards. They may begin at $200,000 and above. That must make it expensive for small makers. The machines require a lot of monitoring and repairing.

This leads to adding of some extra money. It also requires qualified personnel to manage it. The issue of using SMT is challenging for small factories due to a lack of adequate capital investment. They still have to spend more on machines.

Actually, SMT design tends to be rather complex. There are some difficulties arising from the fact that some of the pads are very small, about 0.5 mm. SMT's meaning involves 'tight' traces that require significant design consideration. This leads to the fact that designing takes more time.

They have to be positioned appropriately on the assembly line. This can lead to mistakes being made. They have to think out each move, or the board will not function properly. It is difficult when making high speed devices.

SMT makes phones small and light. It can accommodate very small parts such as 01005 capacitors. The board has a 0.5 mm pad size. The abbreviation SMT also stands for saving space for cameras as well as batteries. That makes phones more effective for calls and apps.

They support high frequencies, up to an operating frequency of 5 GHz. This makes the phones continue performing well and charges with strength. This is how the design helps phones not to get damaged easily when dropped. It makes phones long-lasting.

SMT helps computers to become fast and powerful. It makes use of chips that contain a total of 256 pins. The small parts fit into slim laptops. SMT's meaning also entails assisting CPUs to operate at a speed equivalent to 3.2 GHz. Which leaves large functions such as gaming to computers.

They are quite efficient in handling power up to 100W and do not overheat. They maintain the heat of computers when in use for a long duration of time. They assist computers to run for everyone. They are also light in design to be easily transported from one place to another.

SMT converts watches into smart and small. One is the use of very small resistors that may be as small as the 0201 size in the watch. SMT meaning also encompasses the incorporation of sensors and Bluetooth chips to aid in the phone connection process.

The board also consumes 0.1W to reduce the battery's draw. This keeps the watch running for a long time. These make the watch track steps and show messages. That assists in maintaining watches slim and lightweight. This makes them joyful that they can wear them.

SMT lights up the world with LED lights. It interconnects small LEDs with 0.5 mm pads. SMT also entails the ability to handle 350 mA of current for bright lights.

This makes lights to be long lasting without producing heat. This board is designed with 12 layers in order to cool the LEDs. They stay for a long time in homes. That keeps the lights burning and steady. It helps save energy.

SMT assists enhance the medical devices so that they will be small and beneficial. It deposits small sensors accurateness to 0.25 millimeters. SMT's meaning also encompasses how they are integrated into equipment such as fitness trackers. That assists the doctors in monitoring heartbeats.

They also utilize low-power chips, rated at about 0.5 watts, to ensure low power consumption. This keeps the tools working all day. The ones they make and use are light for the patients to carry along. They can also begin to make important contributions to maintaining the health of people on a daily basis.

SMD is an abbreviation for surface mount device, which refers to small components that are mounted on a board. It connects without wires. SMT's meaning also extends to employing SMDs to facilitate the functionality of small gadgets, such as phones and tablets.

SMA means Surface-Mount Assembly. This assists in placing parts on the board with machines. The abbreviation SMT also extends to applying SMA to assemble devices promptly and sturdily. This makes gadgets to be effective.

SMC means Surface-Mount Components. These are small components. For example, these are 0201 capacitors. SMT meaning involves utilizing the SMCs for space-saving. This enables phones and such like gadgets to remain thin and lightweight.

SMP means Surface-Mount Packaging. It preserves components secure on the board. SMT meaning also involves the use of SMP that prevents objects from continuing to move. This ensures that the devices are strong and do not break down fast.

SME is an abbreviation for Surface-Mount Equipment. It involves the use of machines to guide parts into their appropriate positions in a fast manner. SMT's meaning also involves employing SME to construct gadgets in the shortest time possible. This maintains the functionality of the devices.

PCB refers to a Printable Circuit Board. They retain all the components of electronics which are housed within gadgets. SMT's meaning also comprises of the usage of PCBs to join various things ranging from chips. This makes phones and computers work, or any gadget on the planet for that matter in case you are able to manage to create one.

BGA is a type of chip with little balls at the base. SMT's meaning also encompasses using BGA chips for high-powered computers. That helps the devices to work faster and perform more tasks.

QFP is a package type of chip that has flat pins on its four sides. SMT meaning also entails the use of QFPs to join many parts at one point. This also makes gadgets more effective with many features.

SOIC is a small chip with pins located at the side of the package. SMT's meaning involves the use of SOICs in order to conserve space. This is why smartwatches and other small gadgets have to fit more parts.

TSOP is a flat chip with thin pins like SOP, but TSOP is thinner than SOP. They make devices slim. This assists in making devices slim. SMT also means incorporating TSOPs in tablets and laptops. They help keep them light, and the pieces are compact enough to be carried easily.

TQFP is a thin bag with connection points both on the top and the bottom with pins on the periphery. SMT meaning also encompasses being able to pack more parts because of TQFPs. This is what makes tablets of the like fast and light.

CSP is a miniature chip that could easily fit into the case it comes in. SMT's meaning also extends to the use of CSPs to accommodate more parts. This leads to the creation of small devices with very many functions.

SOP is a small chip with pins at its end. It freely connects to the board. SMT meaning also entails the use of SOPs for wearables. This aids in making gadgets compact and portable.

In SMT meaning, they explain that tiny components like resistors and chips enable devices to run at high speeds. SMT uses small parts to minimize area and contain power. Click on PCBasic to find out how SMT helps the device work!

Related blog: Dual Inline Package Meaning (DIP)

Assembly Enquiry

Instant Quote