Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > The Best Quick Turn PCB Assembly Services from PCBasic

In the rapidly changing competitive environment of the electronics industry, speed and accuracy are the keys to success. Whether you are developing new products or optimizing existing designs, quick turn PCB assembly services is a necessary condition for maintaining a competitive edge.

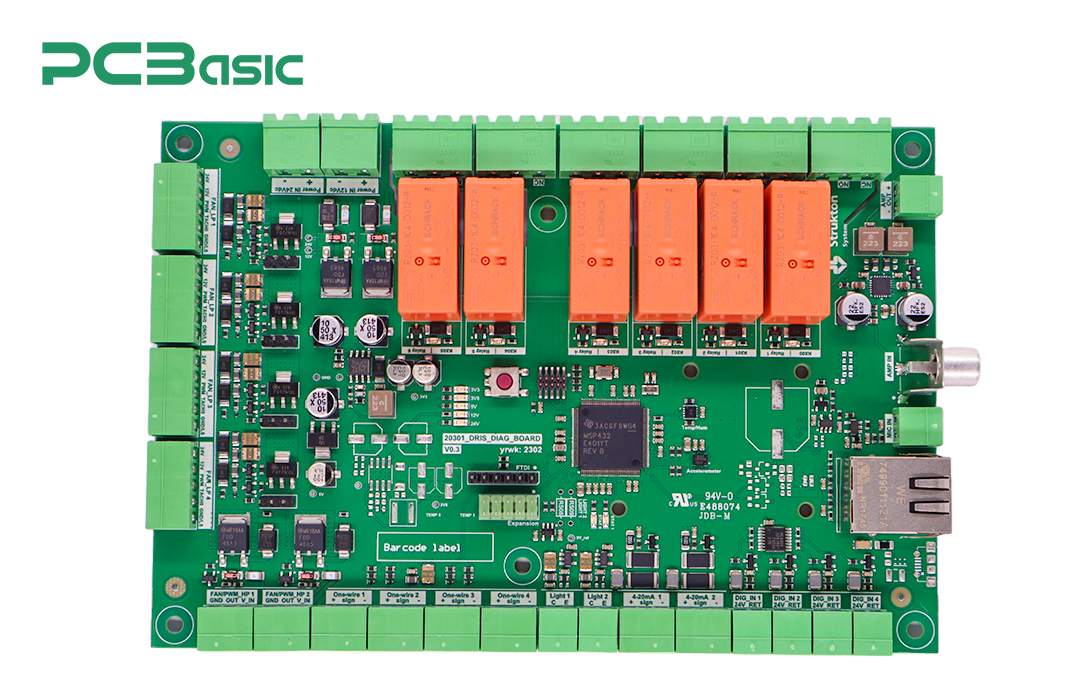

As a leading prototype PCB assembly manufacturer in China, PCBasic offers comprehensive solutions covering all services from fast turn circuit board assembly to those required for mass production. With over 15 years of experience and advanced facilities, PCBasic is your reliable partner providing support for your printed circuit board assembly services.

Quick turn PCB assembly refers to accelerating the manufacturing and assembly process of printed circuit boards, enabling companies to complete high-quality products under tight timelines. This is ideal for prototype PCB assembly and small-batch production, especially when rapid testing and iteration are required. Compared to the weeks required by traditional board assembly, the quick turn PCB assembly can be completed within 24 to 48 hours.

Opting for quick turn PCB assembly services can give companies several key benefits that speed up product development production cycles, and purchase companies precious time in a competitive landscape.

With quick turn PCB assembly, the cycle time of design to delivery of PCB can be shortened to a great extent, Thus, companies can bring in new products at the minimum possible time. Quick turn PCB assembly services usually run from 24 to 48 hours to complete production, whereas traditional board assembly takes up to a few weeks. This is especially true for dynamic industries with an unstable market demand, such as consumer electronics, medical devices, and smart home devices.

Quick turn PCB assembly services not only accelerate production cycles, but also provide prototype testing and design validation early in product development. By quickly manufacturing and assembling prototypes, companies can quickly identify and correct potential design problems in the early stages of product development, avoiding the discovery of design defects after mass production, reducing the time and cost of rework and modifications. This advantage is crucial to the quality control of products, especially in industries such as automotive electronics and avionics, where design accuracy directly affects product performance and safety.

With the diversification of market demand, customers' demand for customized and personalized products is increasing. Quick turn PCB assembly effectively supports unique designs and specialized components to meet individual and customized needs. Through flexible production and assembly processes, companies can customize the size, layout, functional modules, of the board according to customer needs, and even design customized components and components for different applications.

Another advantage of Quick turn PCB assembly is flexibility. In the process of rapid product development, design requirements may change at any time, and traditional production methods are often difficult to adapt to these changes. The fast delivery PCB assembly service supports last-minute design changes, and customers can adjust the design at any time and quickly start production based on test results or market feedback without affecting the overall schedule.

PCBasic stands out as a premier provider of low-cost PCB assembly services. Established in Shenzhen in 2011, PCBasic has over 10 years of experience in PCB design and manufacturing. The company operates multiple facilities, including a small-batch factory in Shenzhen and a large-scale production plant in Huizhou. This infrastructure enables PCBasic to handle everything from prototype PCB assembly to mass production efficiently.

1. Advanced Technology:

PCBasic has independently developed CRM, MES, ERP and IoT systems to achieve intelligent manufacturing, improve production efficiency and quality management. Through CNC precision machining and laser cutting stencil technology, it provides a solid guarantee for rapid prototyping. At the same time, automated inspection systems, such as AOI and X-Ray, fully ensure product quality and meet high standards.

2. Expert Team:

With more than 30 experienced PCB designers, PCBasic has strong technical support capabilities. In addition, the company works closely with university doctoral teams to continuously promote R&D innovation and optimize product performance. The professional quality control team controls the quality of the project throughout the process to ensure that every product meets the highest standards.

3. Certifications:

The company has passed ISO9001, ISO13485, IATF16949 and other international quality certification, and won the title of national high-tech enterprise. In addition, PCBasic has more than 20 patented technologies for quality inspection and production management systems, providing strong support for industry leadership.

4. Efficient Supply Chain:

Relying on the centralized warehouse, PCBasic reserves original and authentic components to ensure a stable and reliable supply. At the same time, it is equipped with an instant BOM import system for quick quotation and material procurement, greatly shorten the delivery cycle, and help customers efficiently promote the project process.

PCBasic’s commitment to speed, quality, and innovation makes it the ideal choice for fast turn PCB assembly:

Comprehensive One-Stop Service:

From PCB layout design to final product testing, PCBasic provides turnkey solutions that simplify the entire process.

Unmatched Speed:

Steel stencils delivered within one hour and fast PCB assembly completed in as little as three days ensure your project stays on track.

High Reliability:

Advanced SMT processes like reflow soldering, wave soldering, and functional testing guarantee robust performance across all products.

Global Reach:

Serving over 120,000 customers across more than 100 countries with a 96.15% on-time delivery rate demonstrates their reliability.

Cost-Effective Solutions:

Low-cost prototype PCB assembly services cater to startups and established businesses alike without compromising quality.

For businesses looking to streamline their product development cycles, quick turn PCB assembly services are a game-changer. PCBasic’s expertise in prototype circuit board assembly ensures high-quality results with unparalleled speed and efficiency. With state-of-the-art facilities, an experienced team, and a customer-first approach, PCBasic is the ultimate partner for your fast turn printed circuit board assembly needs.

Whether you require low-cost PCB prototype assembly or large-scale production runs, trust PCBasic to deliver excellence every time.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.