Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Everything You Want To Know About A PCBA Manufacturer

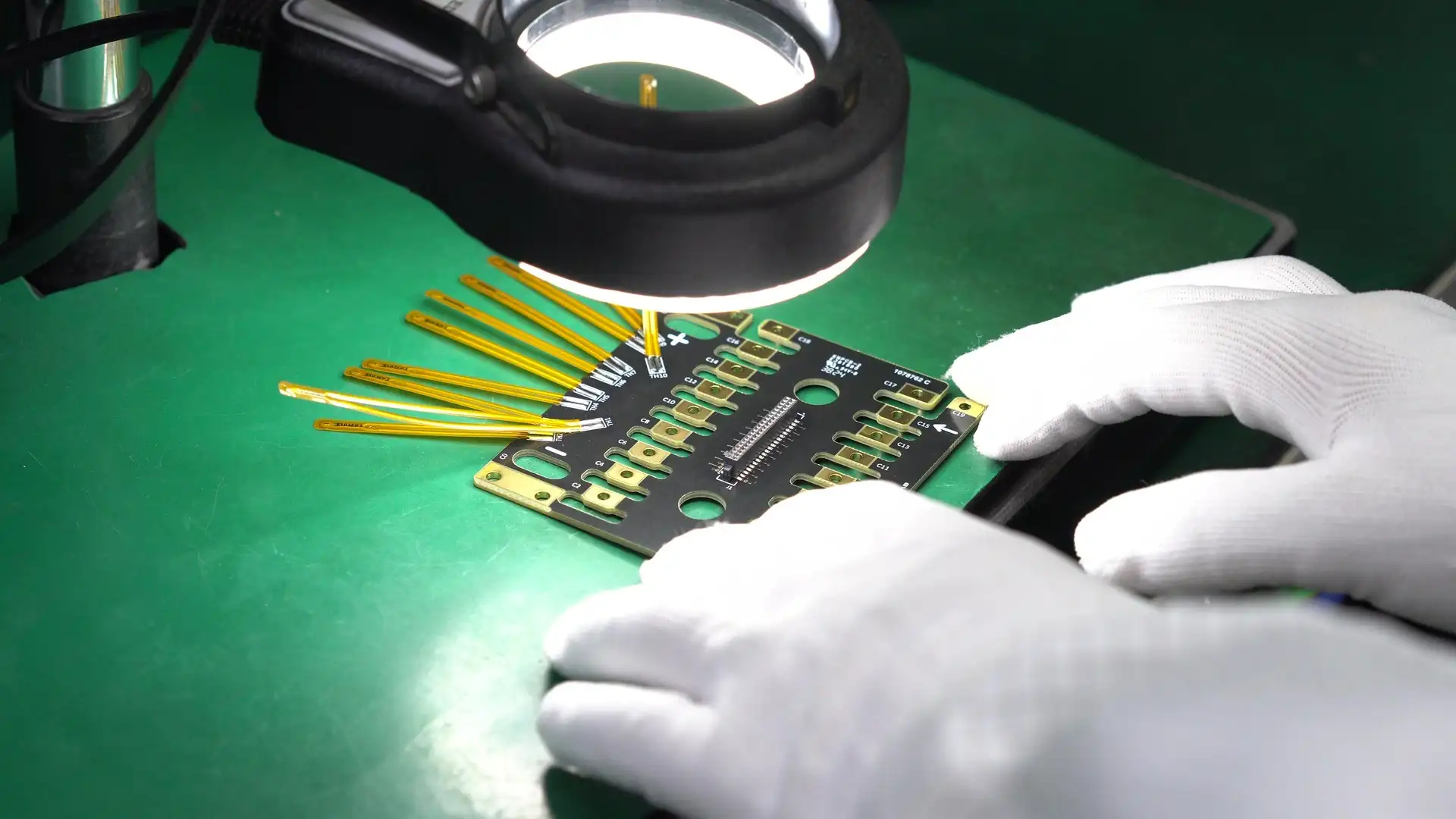

In the electronics industry, PCBA (Printed Circuit Board Assembly) plays an important role in bringing complex designs to life. From smartphones to industrial equipment, the quality and efficiency of the PCBA directly influence the performance of countless products we use daily.

In this blog, let’s learn about the essential components related to PCBA manufacturing and manufacturers, mainly about their brief definitions.

PCBA stands for printed circuit board assembly. It has two main meanings: one refers to the process of assembling electronic components onto the PCB (printed circuit board), and the other means the circuit board that has been assembled. The term PCBA is often used in manufacturing to distinguish between the bare PCB and the fully assembled board.

For example, the PCBA manufacturer PCBasic is not only an intelligent factory focusing on large batch PCBA production but also do one-stop PCB assembly.

The PCB assembly process is to turn a bare PCB into a fully functional circuit board which contains all the required electronic components. The PCBA process is complex, it is mainly consists of the steps: solder paste application, component placement, reflow soldering, through-hole component assembly, inspection and testing.

This is a brief PCB assembly process, if you want to learn the detailed one, you can read this passage.

PCBA manufacturers do PCB assembly according to the design requirements of customers and the information provided by them. A PCBA supplier, PCBA factory and PCBA company are also specialize in manufacturing PCBA, as the same of a PCBA manufacturer.

PCBasic is a well-known PCBA manufacturer in China, focusing on one-stop service and fast multi-variety small-batch and high-volume PCBA production. It is not only responsible for the assembly process and quality control, but also provides Providing R&D solutions, material selection OEM order production, and other services.

SMT refers to the surface mount technology. It is an electronic component assembly method widely used in the PCBA manufacturing process. It does not need to connect the component to a hole in the board through a wire or pin, but instead mounts the component directly on the PCB surface.

The production of PCBA using SMT technology enables miniaturization of electronic products, enabling PCBA to achieve more compact designs, higher component densities and better performance. At the same time, the application of SMT in PCBA can greatly improve production efficiency and accuracy and reduce costs and so on.

PCBA contract manufacturing stands for a company outsources the production of PCBA to a third-party manufacturer. This is a common practice in the electronics industry because it allows companies to leverage the resources and technology of specialized manufacturers without investing in expensive equipment or personnel. PCBA contract manufacturing is popular because it can find professional technology companies to produce, production time is flexible, and it can save costs.

In addition to assembly, the process of PCBA production includes component procurement, PCB design and manufacturing, as well as post-assembly testing. The key stages of PCBA production include: component procurement, PCB manufacturing, assembly and test.

In the rapidly developing electronics industry, working with a reliable PCBA manufacturer is key to success.

Whether working directly with a PCBA plant or through PCBA contract manufacturing, ensuring a smooth and efficient assembly process will result in better products, faster delivery times, and the opportunity to succeed in the highly competitive electronics industry.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.