Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBA Keyboard Design & Manufacturing: A Comprehensive Guide

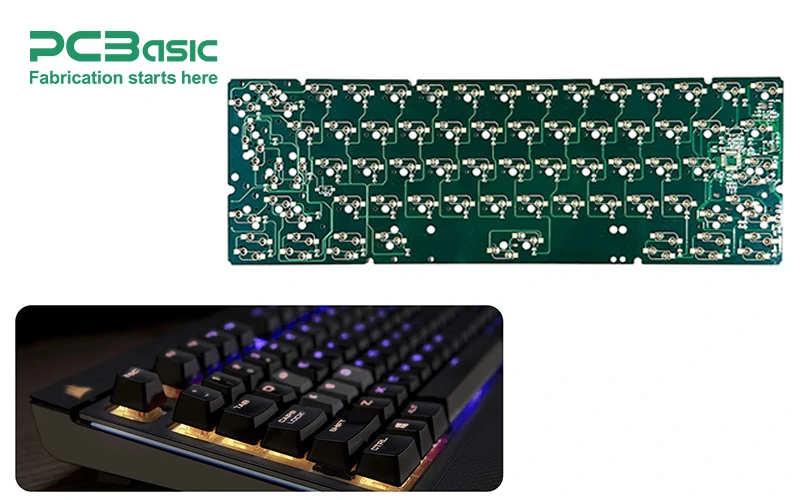

PCBA (Printed Circuit Board Assembly) plays a pivotal role in the production of high-end keyboard assemblies. The PCBA for keyboards connects various components of the keyboard, ensuring its functionality and durability. Whether it’s a mechanical keyboard PCBA or a membrane keyboard PCBA, the keyboard PCB assembly forms the foundation upon which all electrical signals are processed.

The design of the keyboard PCBA is crucial for ensuring that every key press is accurately registered. Proper PCBA keyboard fabrication helps achieve optimal performance and enhances the overall user experience. It is also critical to ensure that the PCBA for keyboard is designed to be durable and efficient, especially in the competitive market of high-end keyboard assemblies.

The PCB in a keyboard connects the various components—such as switches, diodes, and the microcontroller—allowing them to work together seamlessly. The quality of the PCB keyboard assembly is a key determinant in the keyboard's performance, longevity, and reliability. Common materials used in keyboard PCBs include FR4 for standard keyboards, and flexible PCBs for mini keyboards or specialized layouts.

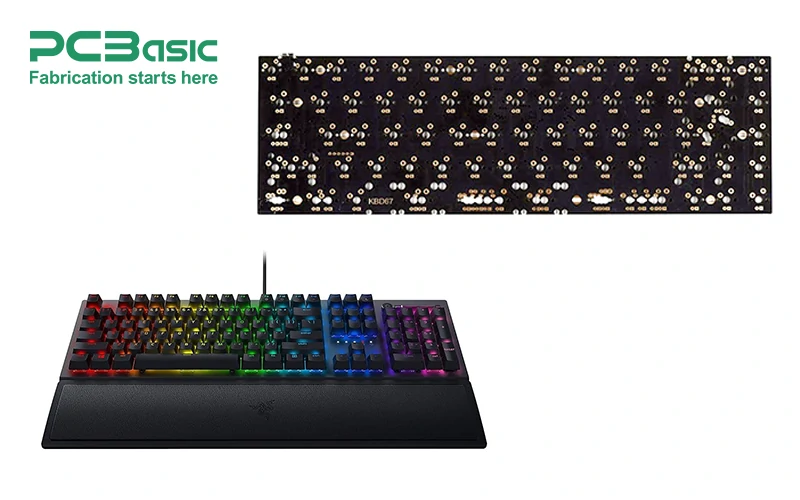

In high-end keyboard PCBA designs, manufacturers often use multi-layered PCBs to optimize the layout and reduce the footprint while ensuring excellent electrical performance. Whether you’re sourcing from a keyboard PCBA factory in China or elsewhere, ensuring the use of the right materials is essential for producing a high-quality keyboard PCBA.

Switches are the most important user interface component in a keyboard. They are responsible for registering each key press. Mechanical switches such as Cherry MX or Razer switches are often used in high-end keyboard PCBA designs for their tactile feedback and durability. These switches work in conjunction with the PCB for keyboard to complete the circuit when pressed.

On the other hand, membrane switches are commonly found in more affordable or slim designs. Both types of switches require precision in PCBA keyboard fabrication to ensure accurate keystroke registration and long-lasting performance.

The microcontroller (MCU) is at the heart of a keyboard PCBA. It processes the signals received from the switches and translates them into keyboard actions. Selecting the right microcontroller is essential for ensuring the PCBA for keyboard functions efficiently, especially for keyboards that offer advanced features such as RGB lighting or macro keys.

When designing PCBA for keyboards, the MCU must be compatible with other components and have the necessary performance characteristics for smooth and fast operation. Choosing the correct microcontroller ensures that the keyboard PCBA assembly can handle complex key commands and interfaces with other devices like computers or smartphones.

Diodes are another critical component in PCBA keyboard fabrication, particularly for preventing ghosting and ensuring that the keyboard registers only the intended key presses. In keyboard PCBA design, each key is typically connected to a diode, ensuring that a key press does not inadvertently trigger other unpressed keys.

Resistors and other passive components such as capacitors help regulate voltage and protect the components from electrical surges, ensuring the keyboard PCBA remains stable and reliable throughout its lifespan.

When designing a keyboard PCBA, one of the first tasks is the key layout design. Arranging the keys on the PCB requires balancing space constraints with usability. High-end keyboards, especially those designed for gaming or professional use, often require a compact yet ergonomic layout. This is essential for improving user comfort, especially during extended use.

The PCB for keyboard needs to accommodate various key sizes, from the standard keys to larger keys like the spacebar or enter key. Traces on the keyboard PCBA must be routed in such a way that minimizes signal interference and ensures a fast response time for each key.

One of the most important design considerations in keyboard PCBA is signal integrity. As keyboards become more feature-rich, it’s crucial to minimize electromagnetic interference (EMI), which can cause erratic keystrokes or even signal loss. Advanced PCBA keyboard design often includes the use of ground planes and shielding to reduce EMI.

In high-end keyboard PCBA assemblies, ensuring that the signal integrity is maintained across the entire board is essential. Proper routing and separation of data and power traces also help reduce the chance of crosstalk and maintain a clear signal path from the key press to the computer or device.

With the increasing demand for wireless keyboards, power management has become a major concern in PCBA keyboard fabrication. Low-power microcontrollers and efficient power circuits are used to prolong battery life in wireless keyboard PCBA designs. Additionally, features such as power-saving modes are integrated into the keyboard PCBA design to minimize energy consumption when the keyboard is not in use.

For wired keyboards, power management is still essential for ensuring efficient operation, particularly for those with advanced features like RGB lighting. A well-designed power distribution network within the PCBA for keyboard can prevent overheating and ensure consistent performance.

Customization is another important aspect of PCBA for keyboards. Many modern users demand customizable key layouts, programmable keys, or additional macro keys. A modular design allows for easy future upgrades or customizations without having to redesign the entire keyboard PCBA assembly.

For instance, the design of the PCBA for keyboard might include support for additional switches or connectors for optional modules. It also needs to accommodate features like hot-swappable switches, a key feature for mechanical keyboards.

In PCBA for keyboards, one of the fundamental choices during the manufacturing process is the soldering technology: SMT (Surface Mount Technology) vs. Through-Hole Technology.

SMT is the preferred method for modern keyboard PCBA fabrication, especially for high-end keyboard PCBA production. This technique allows components to be mounted directly onto the surface of the PCB keyboard assembly, which is ideal for compact and lightweight designs, such as mini keyboards or keyboards with limited space. The primary benefit of SMT is that it reduces both the size and cost of the PCBA keyboard, as it requires fewer through-holes and allows for higher component density. This is particularly advantageous in keyboard PCBA design for achieving a more streamlined and efficient layout.

Through-Hole Technology, on the other hand, is generally used for components that require more physical strength, such as larger connectors or power components. However, it is not as efficient as SMT for compact designs and is typically used less frequently in keyboard PCBA manufacturing today.

The assembly process of PCBA for keyboards consists of several key steps, each crucial to ensuring the functionality and durability of the final product:

Component Placement: The first step in PCBA keyboard fabrication is placing components on the PCB keyboard assembly. This includes switches, resistors, capacitors, diodes, and the microcontroller. Using SMT, components are automatically placed on the board using pick-and-place machines, allowing for high-speed assembly.

Soldering: After placement, the components are soldered to the keyboard PCBA using reflow soldering for SMT components or wave soldering for any through-hole parts. This process ensures that the electrical connections are stable and reliable.

Testing: After soldering, the assembly undergoes rigorous testing to ensure that all components are functioning correctly. This includes checking for shorts, proper connectivity, and ensuring that key presses register accurately.

Importance of Quality Control: Throughout the assembly process, stringent quality control measures are implemented to ensure that each PCBA for keyboard meets the necessary performance standards. Quality checks include visual inspection, automated optical inspection (AOI), and X-ray inspection to detect defects that may not be visible to the naked eye. By integrating quality assurance into each step of PCBA keyboard assembly, the production process ensures consistent, high-quality products.

Testing is a crucial aspect of the PCBA keyboard manufacturing process, as it guarantees the final product meets functionality and durability expectations.

PCBA testing is performed at multiple stages of the process, including electrical testing, functionality checks, and stress tests. For keyboard PCBA, this includes ensuring that the switches work reliably, the microcontroller correctly processes input signals, and there are no issues with the power distribution network.

Key Press Tests are conducted to check the responsiveness and accuracy of each individual key. This helps ensure that no keys are "sticking" or failing to register correctly under various conditions. Electrical testing verifies that the keyboard PCBA handles all electrical signals properly without interference, while stress testing checks the board’s durability under harsh conditions.

Compliance Testing ensures that the keyboard PCBA meets industry standards and safety regulations, including electromagnetic compatibility (EMC) and environmental compliance (e.g., RoHS).

Through rigorous testing, manufacturers like keyboard PCBA factories in China can ensure that their PCBA for keyboards deliver reliable performance and durability, ensuring the final product meets both user expectations and international quality standards.

In keyboard PCBA design, space constraints are a common challenge, especially in high-end keyboard PCBA designs that prioritize compact and ergonomic form factors. The demand for thinner keyboards and more portable designs, such as mini keyboards or gaming keyboards, requires manufacturers to be creative with component placement.

For PCBA for keyboard mini designs, engineers must work within the limited space available on the PCB to fit all necessary components, including switches, microcontrollers, diodes, and capacitors. Proper routing of traces is essential to avoid signal interference and to ensure high performance despite the compact size.

Signal integrity is one of the primary concerns in keyboard PCBA fabrication, especially for keyboards with multiple keys and advanced features. Cross-talk, signal interference, and electromagnetic interference (EMI) can cause key presses to be misregistered or delayed.

To prevent these issues, designers use advanced techniques like ground planes, shielding, and differential pair routing to maintain signal clarity. The careful layout of traces and the selection of high-quality materials for the PCB keyboard assembly also help maintain signal integrity and reduce the risks of data loss.

High-performance keyboards, especially those with features like RGB lighting, wireless capabilities, or high-speed switches, generate significant heat. Effective heat management is critical to ensure that the PCBA for keyboard functions optimally without overheating or compromising component longevity.

Designers must carefully consider thermal dissipation when designing the keyboard PCBA. This may involve the use of heat sinks, thermal vias, and passive cooling methods. For wireless keyboards, efficient power management plays a significant role in preventing overheating during use.

In conclusion, the PCBA keyboard design process involves multiple critical considerations, including component placement, signal integrity, power management, and customization. By leveraging advanced PCBA for keyboard techniques, manufacturers can create keyboards that meet high standards of performance, durability, and user satisfaction.

At PCBasic, we pride ourselves on our expertise in PCBA for keyboard design and manufacturing. Our commitment to quality and innovation ensures that we deliver high-end, reliable, and performance-driven keyboard PCBA solutions to our clients. Whether it’s for high-end gaming keyboards or mini keyboards, we provide customized solutions that meet the specific needs of our clients while adhering to the highest standards of quality and precision.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.