Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > The necessity and steps of the PCBA functional test

PCB production and processing depend on testing. PCBA testing is crucial. Despite this, some customers doubt its necessity. Some people might assume that testing is unnecessary and that everything should work without it. In this article, PCBasic, a turnkey PCB assembly manufacturer, will explain why and how PCBA testing is necessary.

Even if a PCBA board passes production inspections such as SPI, AOI, and QC, during its production process…

Engineers verify if the circuit board functions as intended through full-featured testing. They simulate the actual working state and user environment to ensure normal program operation. The PCBA board is tested against product design functional requirements to meet specifications. This testing also identifies areas of potential board design improvement.

PCBA functional testing detects functional defects in circuit boards before product assembly. This test prevents wastage of man-hours and materials due to dismantling and repairing. It ensures delivery quality and final performance parameters of the PCBA product.

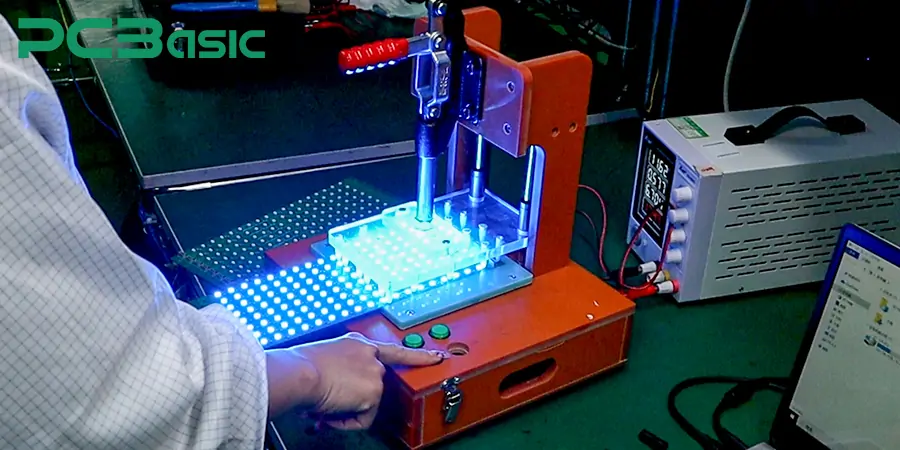

The FCT test fixture is made based on customer-designed test points, programming materials, and test steps. Then, the PCBA board is placed on the FCT test stand to complete the printed circuit board testing process.

The test stand obtains typical values, such as voltage and current, to observe if the circuit board circuit turns on . It verifies input and output actions are consistent with the design, completing the entire PCBA board test.

The PCBA testing principle connects PCB pads or test points through metal probes of the FCT test stand, forming a complete path. The program is burned, and the PCB board is powered on to simulate user actions.

Typical values, such as voltage and current, are obtained via the FCT test stand. This allows observation of circuit functionality and verification of the original design functions.

PCBA functional test requires customers to provide a DFM guide, PCBA board test points, SOP data, etc… Sometimes there might be a need for programming materials. Materials might include information such as standard voltage/current values between test points, allowable error values, etc… Sometimes test steps, and other test documents and tools will be necessary as well.

The PCBA test process is generally determined by the customer’s test plan. But, the general PCBA test process includes program burning, ICT test, FCT test, and burn-in test/drop test.

Let’s talk about program burning and burn-in/drop testing first, and focus on ICT and FCT testing later.

Program burning test

engineers burn the program onto the single-chip microcomputer in the PCBA board after processing. This “transfers” the program to the IC, enabling the product to execute specific functions upon turning it on.

Aging test

The PCBA board is powered to simulate daily use environment factors such as temperature changes, electric power, etc… This test detects hard-to-find defects, component parameter mismatches, and debugging failures. By being able to solve those problems, we can ensure product stability.

Drop test

The PCBA finished bare board undergoes drop testing from several angles at a position of up to 1 meter above the ground. Optimization is necessary if issues arise until the bare board passes the drop test. After the bare board test, the manufacturer packages the product and performs a drop test to simulate the global transportation scenario. manufacturer does this test to prevent damage during manual handling and car transportation.

Functionality testing points

After getting the information provided by the customer, the test engineer first looks at the test requirements, such as:

● wiring requirements;

● voltage output

● functional requirements (whether the direct voltage of the two test points is within the pre-defined data points)

After the engineer has debugged the program, he will record a video during the test for the customer to confirm. After confirming that the measurement process and results are ok, they will be distributed. The test team members will then use it to batch testing.

Pay attention to this:

● Electrostatic protection;

● The positive and negative values of the components on the test board

There are a few differences between ICT and FCT tests. Let’s cover and compare both tests t understand which one works better for us.

The full name of ICT is Information Communication Technology. This term is also the abbreviation of the online tester. ICT (circuit test) is mainly aimed at the component level. The ICT test mainly touches the test point of the PCB layout by the test probe. During the test, it touches the pins of each component on the PCBA board and measures whether the values consistent with the nominal values. During the test, we use the form of “conduction” to energize each line. We use this test to ensure the connectivity of the lines. ICT test can also check whenever there’s a short-circuit, open-circuit, tin, etc… The accuracy of the ICT test is relatively high, and it can show which component or location is faulty. It can show the cause of an open circuit or short circuit, thus it has a wide range of applications.

ICT’s blind area requires designing the test points during the PCB board design process; otherwise, the test cannot proceed. ICT testing depends on customer needs and typically serves large-volume orders. Those components cost around four to five thousand dollars per piece. Often, they need customization to fit customers’ needs.

FCT test

The FCT test is mainly aimed at the functional test of the board. It is necessary to make an FCT test bench according to the design documents. The test bench has many wires connected to the thimble. The FCT test can find problems in hardware and software. It is a functional test close to the product level. It can test the PCBA’s environment, current, voltage, pressure, and other parameters. Thus we can cover most if not all the product performance range.

Compared with the ICT test, the FCT test method is simpler, it can be tested directly by connecting and outputting, and most orders are tested by FCT. The FCT blind zone means that the reliability of the board cannot be tested (ICT can). The content of the FCT test is relatively comprehensive, so before the test, you can know which points the customer needs to pay attention to. Then, to meet customers’ demands, we will pay attention to it during the test.

PCBA testing enhances product pass rates and enables manufacturers to maintain high-quality standards. The process detects and repairs faulty boards, improving product quality. PCBasic recommends PCBA testing for every product, if possible.

Why is PCBA testing important and what distinguishes ICT and FCT testing? That's PCBasic's answer. Stay china PCB assembly updated by following PCBasic or contacting us through the email on the right!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.