Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Understanding PCB Rulers: Your Ultimate Guide

Key specification and precision in design and assembly process for PCBs is crucial. The device's standard size affects assembly success whether you are designing a simple circuit board or a complex multi-layer design. Every PCB designer should have at least one PCB ruler (or called circuit board ruler). Although it sounds like a simple tool, the PCB needs to be validated before it goes to the manufacturing and assembly stage.

In this ultimate guide, let’s talk about what a PCB ruler is, the features of a PCB ruler, how to choose a PCB ruler, and how to design your own PCB ruler.

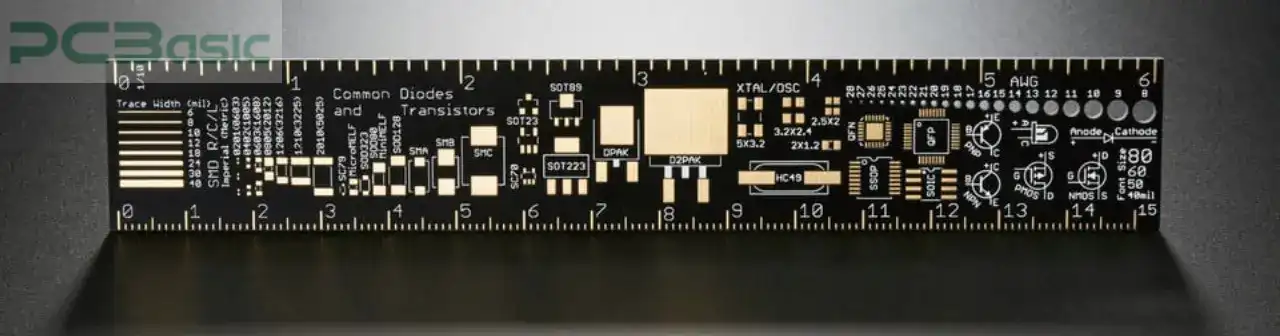

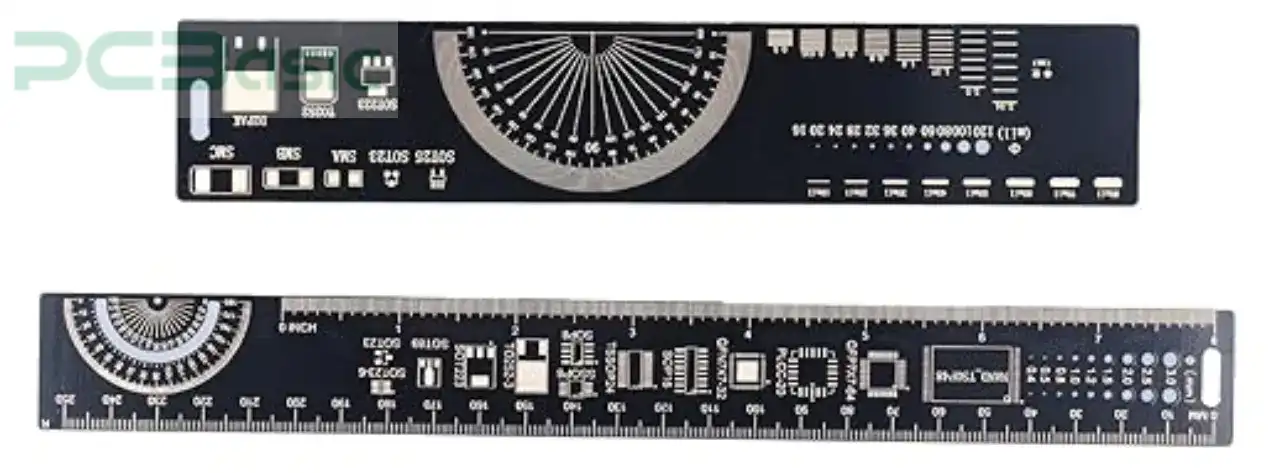

The PCB ruler is a unique measuring tool that is utilized by designers and engineers to make sure accuracy in the design and assembly of printed circuit boards (PCBs). It's specifically for circuit boards and helps users accurately measure component sizes, trace widths, and component layouts. Unlike ordinary rulers, PCB rulers typically feature specialized scales related to PCB design and manufacturing.

So essentially, a PCB ruler is a guiding tool to make sure that every measurement while designing the PCB falls within the industry standard values to ensure that the circuit designed works as expected. This tool is an indispensable part of assembly and manufacturing of PCB as it holds every part of the components on the circuit board with precise alignment.

The PCB ruler has been vital because it performs multiple functions in the PCB design and PCB assembly process:

• Accuracy in Measurements: PCB ruler measures the size and placement of every single component perfectly. It helps in avoiding mistakes while manufacturing the board and makes the board to be functional.

• Optimizing Space: A PCB needs to fit multiple components in a small area. This is particularly useful when trying to fit a number of components onto a board. The circuit board ruler helps designers to make sure that the component layout is efficient, avoiding overlaps and ensuring enough space for the routing.

• Trace and Gap Precision: During PCB fabrication, the width of traces and the gap clearance in between them are crucial parameters for the performance and manufacturability of the circuit board. A PCB ruler is used to verify if the trace width and spacing are in compliance.

The circuit board ruler is not a common ruler. It has numerous features built particularly for PCB fabrication. Below are some descriptions of these features and how they help optimize your PCB design.

The accuracy of a PCB ruler has its importance, particularly for smaller components like surface-mount devices (SMDs). Markings on the tool often guide measurements to within fractions of a millimeter, ensuring each component is positioned correctly. In PCB assembly, there is a minutiae errors which may lead to poor connection or misalignment of component which during soldering may make PCB unusable.

With a PCB ruler, you can measure the distance between component pads and assist in limiting enough distance for better soldering. This is particularly critical for fine-pitch components.

In PCB design, trace width is essential for the PCBs behavior. A trace that is too narrow will not carry enough current while, one that is too wide will waste design space that could be otherwise leveraged better. A PCB ruler helps designers to widen or shrink trace width as per required electrical properties and manufacturability.

By having trace width measurements on a circuit board ruler, designers will be able to ensure their designs are in line with industry standards, and that their traces have adequate traces for the current load they expect. This can result in an cost-effective and quick method of PCB manufacturing.

The PCB ruler has the other main purpose of giving designers a sense of what size components might look like and how they will fit into the space they have set aside for a PCB. In some cases, especially when dealing with compact devices, the measuring of size components is also essential. A PCB ruler helps designers quickly ensure that components are the correct size and fit with one another when assembling a PCB.

Also, circuit board rulers have become useful when it comes to visualizing component placement with each other. This is critical in the case of complex boards that have multiple components, or when you're trying to squeeze the board into the least area possible while maintaining the performance.

Which PCB ruler is the most appropriate for your design and PCB assembly needs depends on a number of factors. Here are a few tips to help you make the best choice:

• Scale and Precision: Go for a high-precision PCB ruler. For most boards, a PCB ruler that has a scale in both mm and fractional measures will suffice. There are rulers that feature precision ending in 0.1mm, which is sufficient for most current PCB sizes.

• Material: Although plastic rulers are lighter and more convenient, metal should be selected for strength and greater durability. If it is a tool that will see frequent use in the workshop, a metal PCB ruler may be more suitable.

• Additional Features: Some provide more than just a ruler; you may find integrated protractors for angle measurement or grids for easier alignment. If your designs need something extra in the way of measurement or alignment, this will come in helpful.

• Size: Depending on your PCB size, you need to consider the size of the ruler as well. Some rulers are small, but others are of large size and most effective for measuring large boards.

If you are looking for a fun homemade tool and have some design type in mind, making your own PCB ruler can be a formidable challenge, and in the same time a rewarding thing to use! You can design a simple custom ruler consisting of marking a couple of measurements in a transparent material or take it a step further and build a custom ruler with PCB assembly features relevant to your design.

First, a PCB ruler is made from something durable materials such as plastic or even metal. Mark out the measurements for component dimensions, trace width, and the distance pad. If it’s possible, using a laser cutting which can create a really precise and professional PCB ruler that represents unique requirements.

You can even design a custom circuit board ruler to include things like component alignment guides or custom trace-width guides for your specific type of PCB design. This also guarantees that your ruler will adapt perfectly to your PCB manufacturing.

A PCB ruler is a necessary tool in PCB design, PCB assembly, and PCB manufacturing. It makes sure that your components, traces, and the entire design conform to the tolerances needed to achieve the precision you want for better performance, reliability, and easier assembly. Now, regardless of whether you’re a new beginner or you have been around for a long time in PCB design, a high-quality circuit board ruler can always come in handy for smoothing the design and manufacturing process.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support