Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCB Inductors: A Comprehensive Guide to Fundamentals, Design, and Applications

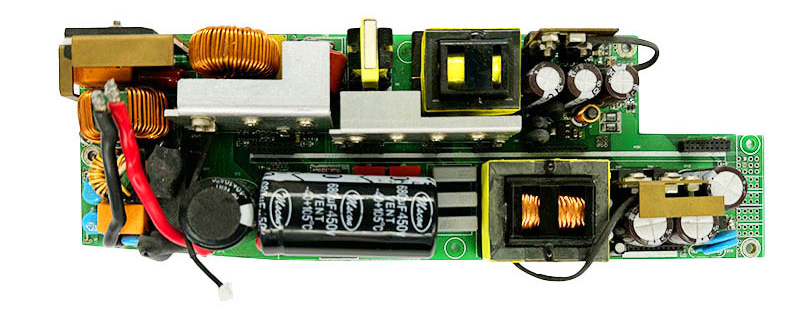

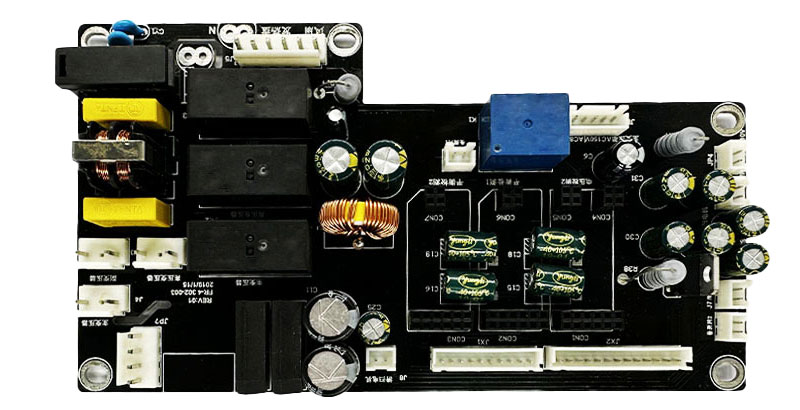

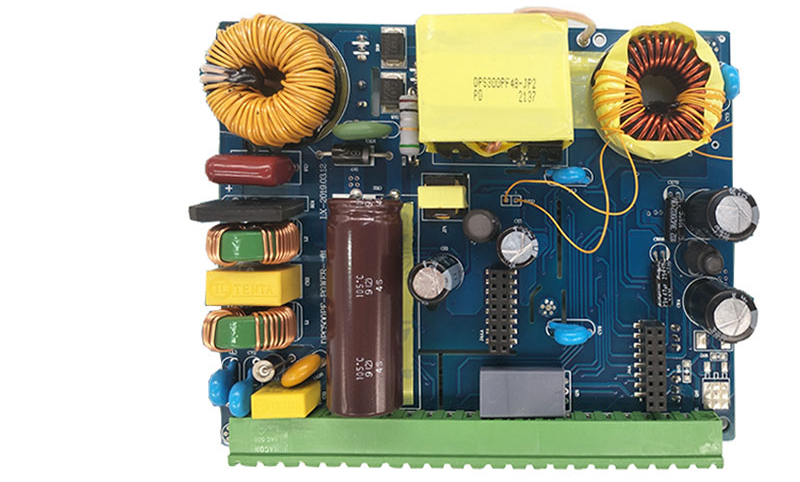

Unlike capacitors, PCB inductors are passive components that work on electromagnetic principles and stores energy through a magnetic field when a current passes through it. These circuit board inductors are indispensable in modern electronics as they play a vital role in voltage regulation, signal filtering, energy storage and ensuring the stability and efficiency of various systems. Whether you are designing an inductive PCB for a power supply, communication circuit, or filtration application, understanding the role of a PCB inductor coil is key to achieving optimal performance.

In the power supply circuit, the inductor on the PCB stores energy through the magnetic field, and it is released when needed, which is very important for the power supply circuit, mainly for regulating current and stabilizing voltage. One type of power inductors is a key component of power converters, regulators and inverters (mainly used to reduce power noise and smooth output current), and its reliability in high-performance equipment is critical. In the field of signal processing, circuit board inductors are used to filter high-frequency noise (inductors and capacitors form LC filters, which can shield unwanted high-frequency noise) and maintain signal stability. PCB inductor coil is used in RF circuits to filter and tune frequencies to ensure the clarity of wireless communication signals.

Nowadays, there are more and more types of PCB inductors to adapt to different uses, functions and design needs (for example, specially designed pcb inductor coils can be used for inductive wireless charging or near field communication (NFC) functions). In circuits that require tuning and resonance, PCB inductors are also indispensable (eg. PCB inductor coil and capacitor LC circuit, used to set a specific resonant frequency). Inductors on circuit board can also protect the circuit, inhibit the influence of current mutation on the sensitive components, and enhance the stability of the overall system. In short, PCB inductor is very important for electronic equipment and circuit boards. Below, let's take a look at what types of inductors there are!

Selecting the right inductor type is critical for achieving the desired circuit performance. The followings are different classifications of PCB inductors, let’s take a look together! If they are not detailed enough, you can help me to supplement by sending the content that needs to be supplemented to our email.

|

Core Material |

Description |

Common Applications |

|

Iron Core Inductors |

High energy efficiency and permeability |

power inductors |

|

Air Core Inductors |

Free from core saturation, ideal for high-frequency applications |

High-frequency circuits |

|

Iron Powder Inductors |

Offer reduced core losses, suitable for low-frequency applications |

Circuit board inductors |

|

Ferrite Core Inductors |

Compact and efficient, favored in high-frequency designs |

High-frequency PCB inductor designs |

|

Toroidal Core Inductors |

Unique shape minimizes electromagnetic interference |

Compact and EMI-sensitive circuits |

|

Laminated Steel Core Inductors |

Durable and designed for heavy-duty industrial use |

Power inductors in industrial applications |

|

Component Structure |

Description |

Common Applications |

|

Shielded Variable Inductors |

Useful in tuning circuits |

Tuning and frequency adjustment circuits |

|

Multilayer Chip Inductors |

Compact and surface-mountable |

Miniaturized electronic devices |

|

Shielded Surface Mount Inductors |

Reduce EMI, enhancing performance in high-density PCB designs |

High-density PCB designs |

|

Wireless Charging Coils |

Specialized PCB inductor coils used in wireless power transfer systems |

Wireless charging and power transfer |

|

Coupled Inductors |

Often found in multi-phase converters |

Multi-phase converters and power systems |

|

Application Usage |

Description |

Common Applications |

|

Radio-Frequency (RF) Inductors |

Used in RF circuits for tuning and maintaining signal integrity |

RF circuits and communication systems |

|

Molded Inductors |

Suitable for automotive and industrial use |

Automotive and industrial electronics |

|

Color Ring Inductors |

Easy to identify, commonly found in low-power circuits |

Low-power consumer electronics |

|

Variable Inductors |

Provide adjustable inductance values for fine-tuning applications |

Precision tuning circuits |

|

Chokes |

Specialized inductors on PCBs used to suppress AC noise in DC circuits |

DC power supply and noise filtering |

Here is a step-by-step guide to designing PCB inductors for a variety of applications based on relevant experience and expertise . I'm sure it will be very helpful.

To design a PCB inductor, you must first understand the energy storage and filtration requirements of a good circuit. Because the inductor on the circuit board is usually used to adjust the power supply, filter the signal, and store energy, the inductance value required depends on the operating frequency and current size of the circuit. For example, when we want to effectively manage the energy conversion of a DC-DC converter and minimize its ripple, we need a specific value of inductors.

The following table is for your reference:

|

Core Type |

Characteristics |

Application Scenarios |

|

Ferrite Core |

Suitable for high-frequency applications, reduces losses and improves efficiency |

such as RF circuits or high-speed switching regulators |

|

Iron Core |

Suitable for applications requiring higher inductance and current handling capacity |

Power inductors for low-frequency power applications |

|

Core Size & Shape |

Must be optimized based on available PCB space to provide the required inductance |

General application |

The choice of core materials (like type, size, size) will affect the inductance value, efficiency and frequency response of the PCB inductor coil, so we have to choose according to the corresponding application!

In the design of PCB inductors, be sure to choose the number of windings carefully. The higher the number of windings, the higher the corresponding inductors value will be, and the higher the inductors value will require more PCB space, so it is necessary to choose the correct and appropriate inductors value. You can calculate the number of windings using the following formula:

Among them:

· ·L is the inductance (unit: Henry),

· ·N is the number of windings,

· ·μ\mu is the permeability of the core material,

· ·A is the cross-sectional area of the core,

· ·l is the length of the magnetic circuit.

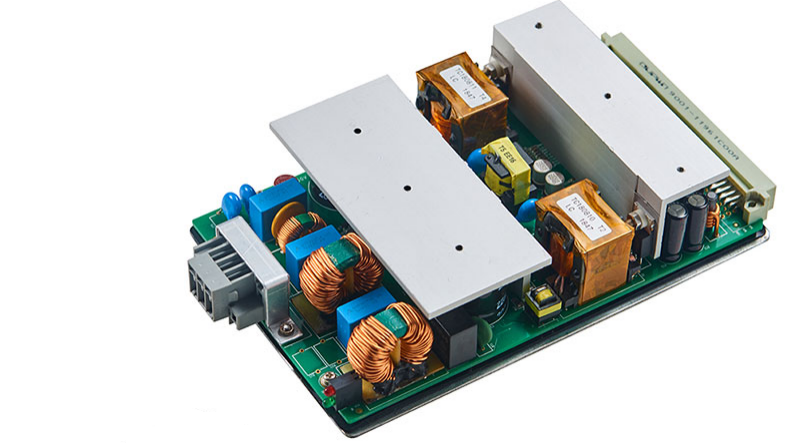

The wire diameter affects the heat and resistance generated when the current flows through the PCB inductor: although the thick wire diameter can reduce the resistance, it occupy more space; Wire too thin can provide higher inductance, but is not suitable for high current applications. If you want to use the power inductor in the power supply circuit, then be sure to choose a line diameter that can balance the current handling capacity and resistance, which is the key to improve efficiency.

The shape and layout of the circuit board inductors are also important, affecting the design of the circuit to minimize parasitic effects* (such as parasitic inductors and capacitors) and can interfere with other components if the inductors are improperly placed on the board. So be sure to define the right shape and layout. Common coil shapes include helical, hexagonal, and rectangular, each of which has unique advantages in terms of space efficiency and inductance uniformity.

*Minimizing Parasitic Effects means that in circuit design, the non-ideal effects caused by the existence of circuit components and circuits are minimized by optimizing design and selecting appropriate materials, layout, etc., so as to improve circuit performance and stability.

Parasitic capacitors and resistances are unavoidable phenomena in PCB inductors and require careful design to minimize them. In addition to the fact that coil shape and layout can affect the parasitic effect, we can also shield the inductor by optimizing the width and spacing of the wires and using the ground plane to avoid unnecessary resonance caused by parasitic capacitors and reduce the signal filtering ability of the inductor.

Before finalizing the PCB inductor design, use appropriate simulation tools to verify the performance of the inductor (these tools can help analyze key parameters such as inductor value, resistance, and self-resonant frequency to ensure that the inductor on circuit board meets design specifications). If the test is ok, then there must be no problem.

Note: When conducting simulations to test, the power inductor needs to be evaluated for its overall effect on circuit performance under different current and voltage conditions.

Here, I will only list three main principles for placing inductors on the circuit board:

First, noise. Due to the working characteristics of the inductor, electromagnetic interference may be generated when it is working, thus affecting the performance of the surrounding sensitive components. Therefore, when placed, try to stay away from noise sensitive components to reduce interference and ensure reliable operation of the circuit board.

The second is thermal management. The inductor will generate heat during operation, so before preparing for placement, ensure that there is sufficient spacing between the inductor and other components for effective heat dissipation.

The third is electromagnetic interference. PCB inductors should be properly arranged to prevent electromagnetic coupling from affecting signal integrity and circuit performance.

So much for the discussion of PCB inductors in this paper. Previously, we discussed the definition, importance, type, design guidelines, and principles for placing inductors on a PCB. PCB inductors are essential for designing efficient and reliable electronic circuits. By choosing the right inductor type, accurately calculating the inductor value, and following best practices for inductor PCB design, we can optimize the performance of the board and ensure long durability. I hope this article was helpful to you. If you have any suggestions, please send them to us via LiveChat! Thanks for reaching out PCBasic!

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.