Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCB Box Build Assembly and PCBasic’s Advantages

The assembly of electronic devices is pretty much just done by placing components in a box. Building the box is known as "box build assembly." It is like building blocks but for electronics.

It takes more work to put parts in boxes than to place them. The gist is to ensure that everything works and remains united.

Suppose you need circuit board assembly help creating early electronics prototypes. In that case, you should do user testing on your design to ensure that it functions as intended. This is where prototype circuit board assembly comes into play. In this situation, PCBasic has the expertise to give optimum solutions.

It is the last step of electronic product manufacturing, known as box build assembly. This is how you make a circuit board, solder all the parts, and put them in a box or case. However, box build assembly is more than just a simple approach to loading components into a box.

What box build assembly does consist of:

1. Always put the correct box on the circuit board.

2. Connecting and wiring various components.

3. Adding cables and connectors.

4. Hiding all the other moving parts under the hood

5. Testing the final product to ensure functionality

Essentially, box build assembly involves installing all the individual components of an electronic device into the final product.

Here are the steps for making a box build prototype circuit board. So, let's get started:

First, you see, you need a plan. Think about everything you need to do before you start building. Decide all the actions you'll need to take. Look closely at all the design papers for your electronic device. Then, make a complete list of all the parts you will need to build it.

Next, get all the parts. You need to buy or gather everything required for your prototype. For prototypes, you'll definitely need the circuit board itself, the box or enclosure to put it in, wires to connect things, connectors to plug things in, and other mechanical parts. It's important to get good quality parts that will work well.

Then, put everything together carefully to make the final product. This is the actual building step. Start by putting the circuit board in the box or enclosure. After that, use wires to connect all the different parts inside the box. Make sure all connections are secure. Also, add any other mechanical parts that are part of the design at this step.

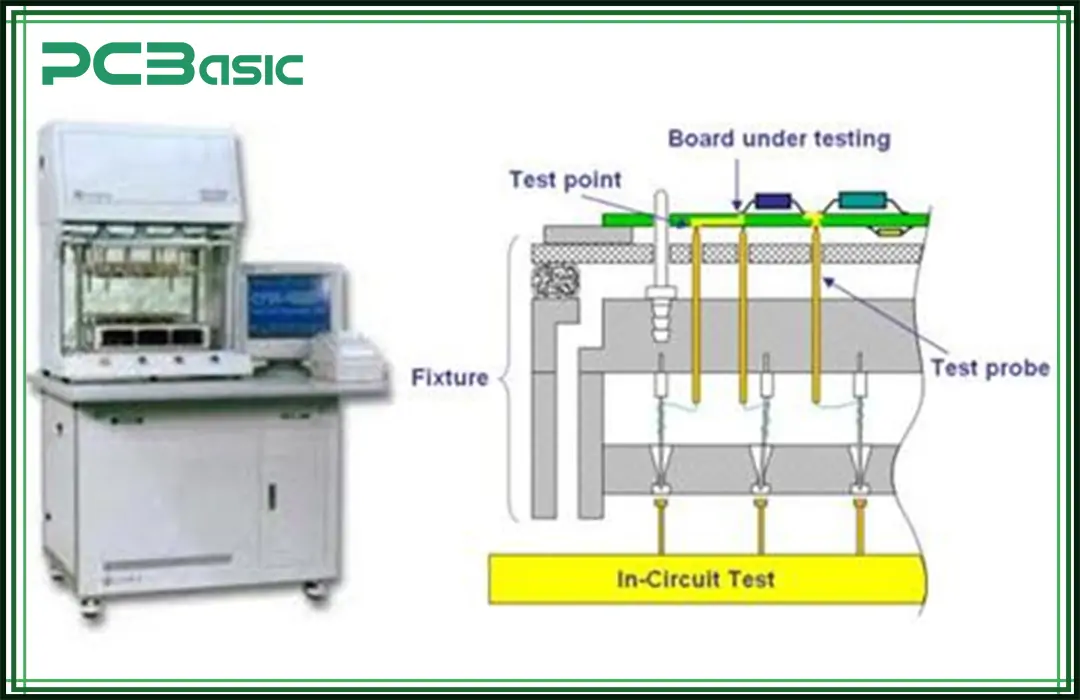

Next is testing. This is the point, it's a very important step after you put the box together. You need to check if your prototype works as it should and does what it is designed to do. Testing includes carefully checking if every wire and connector is in the right place and connected correctly. Also, check if the power turns on properly. Finally, all the main functions of the device must be tested to make sure they work as expected.

Checking for Mistakes-Inspection

Finally, check everything one last time. Inspect the fully assembled product to make sure it’s put together correctly and looks right. This is the last step before considering the prototype complete. Often, a circuit board assembly service will do this final check. They will carefully verify if all parts are put in correctly and without any mistakes.

When making prototypes, we pay close attention to each and every step. The main goal of all these steps is to create working prototypes that we can use for thorough testing.

Box build prototypes are useful for many different purposes. Almost every new electronic device created needs these prototypes during development. Here are just some examples of where they are used. In simple words, let's look at some examples:

New consumer electronics like phones, tablets, and smartwatches commonly use this box build method. Companies test these prototypes thoroughly to check the designs and features before starting to make large numbers of them for the public. Got it?

New medical tools and equipment, like patient monitors in hospitals and medical testing machines, need very careful prototypes. This is crucial to make absolutely sure they are safe for patients and doctors and that they work perfectly and reliably every time.

Machines and complex control systems used in factories and industrial settings often need prototypes. These prototypes help test if the equipment is strong enough, durable, and works reliably in tough working environments and conditions.

Cars today have a huge number of electronic parts and systems. From engine control boxes to in-car entertainment and navigation systems, prototypes are extremely important. They help make absolutely sure all these complex electronic systems will work correctly and safely inside vehicles.

In airplanes and spacecraft, all electronics must work perfectly and without any failure. This is because lives depend on it. Prototyping for aerospace electronics is therefore extremely important for rigorous testing and detailed verification of these critical systems before they are used in flight.

The turnkey box build prototype assembly has lots of good things to it. You will notice it can really make making prototypes much easier and faster. Let's see why:

With turnkey box build circuit board assembly, one company does it all. So, you don't have to spend your time looking for different companies for parts, putting things together, and testing. This really saves you a lot of time.

It can also cost less money. You see, when you use just one service for everything, it can be cheaper than using lots of different services. It's like buying a meal deal instead of buying each item separately!

This is the point: you only need to manage one company. This makes the whole process much simpler for you. In simple words, you have just one person to talk to for everything you need. Got it?

Turnkey companies are usually experts at box build assembly. They have the know-how and the right systems to make sure your prototypes are really good quality. You will notice the difference.

Because it saves time and makes things simpler, the turnkey assembly can help you get your product ready to sell faster. This is super important, especially if you are in industries that move very quickly.

When you are looking for a company for box build prototype PCB assembly services, PCBasic stands out. PCBasic has many advantages that make it a great choice.

PCBasic has a team with over 10 years of experience in PCB design and project management. Now, this is an important point. This means they know what they are doing. They have the knowledge to handle your prototype project well.

PCBasic works with PhD teams from universities. This collaboration brings new ideas and research into their work. It means they are using the latest knowledge and methods.

PCBasic has factories in different locations. They have a small-batch factory in Shenzhen and a large-batch factory in Huizhou. This gives them the flexibility to handle different project sizes.

They have their own stencil and fixture factory and a CNC precision parts processing. This means they control the quality and speed of these important parts of the process. Stencil delivery within 1 hour is very fast, showing their efficiency.

PCBasic has a central warehouse for intelligent electronic components. They guarantee original and genuine parts. This is very important to get a quality prototype for your project.

Their one-click BOM import and instant quoting system make it easy to get started. You can quickly get a quote and begin your project.

PCBasic is a national high-tech enterprise with many certifications, such as ISO13485, IATF 16949, ISO9001, ISO14001, and UL. They are also IPC members and have been awarded over 20 patents for quality and production management. These all show their commitment to quality and good practices.

In simple words, PCBasic offers experience, advanced technology, flexibility, quality control, and efficiency for your box build prototype PCB assembly needs.

The manufacturing process of box build prototype PCB assembly serves as an essential step to produce electronic products. The process requires proper assembly of all parts combined with functionality testing. The process becomes simpler and more efficient through the use of turnkey services.

The selection of a partner for this critical phase provides several benefits through PCBasic's services. It incorporates sophisticated facilities combined with an emphasis on quality and efficiency. These distinctive features make it a professional choice for your box build prototype PCB assembly needs. Furthermore, you will get reliable and quality prototype assembly services for manufacturing needs.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.