Within the intricate world of electronics, where innovation's supremacy is undeniable, one component, yet often overlooked, plays an essential role: the LPI Solder Mask. This small feature is the most critical part of every Printed Circuit Board (PCB), and it is the link that turns an idea into a physical object. We will learn everything about LPI masks, how they work, their applications, color diversity, their role in the assembly, and many more. Stay tuned with us!

What is the LPI Solder Mask

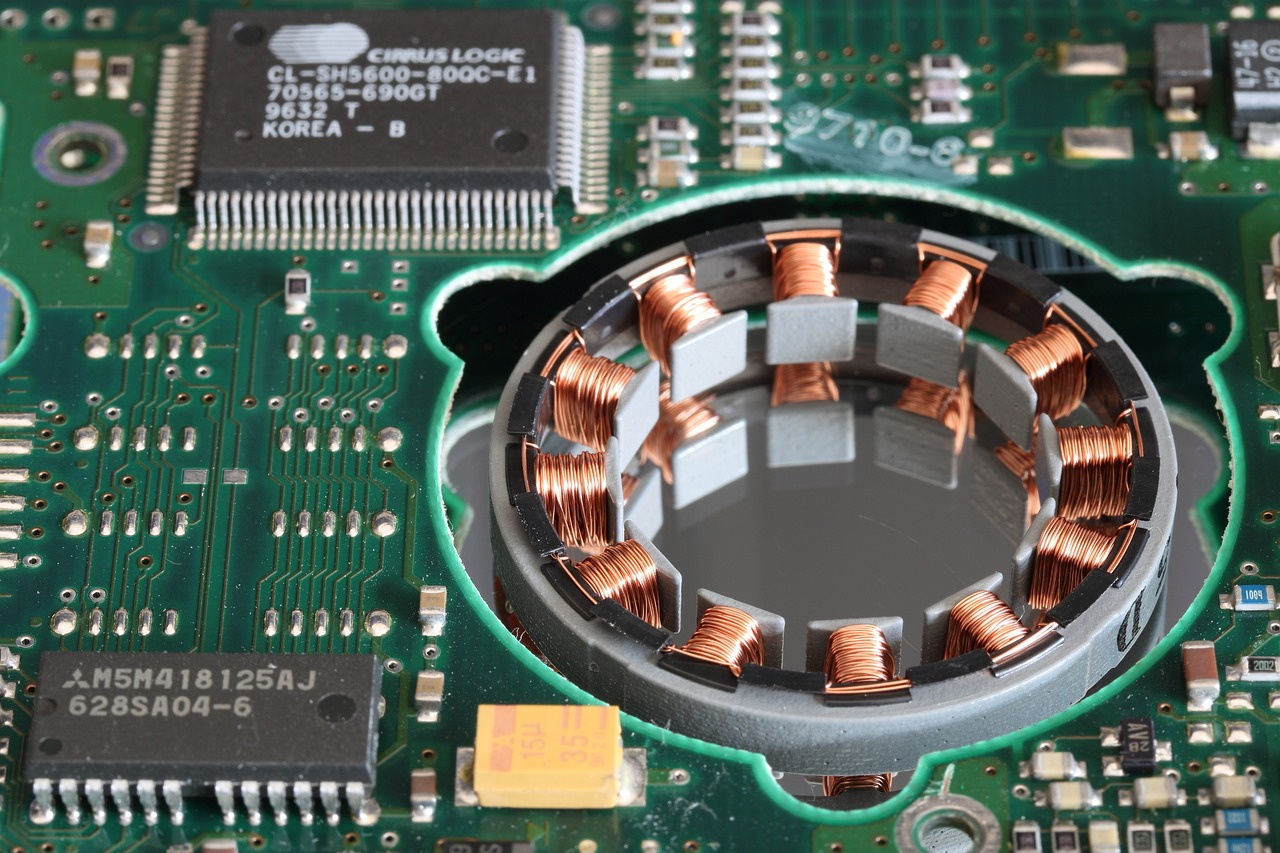

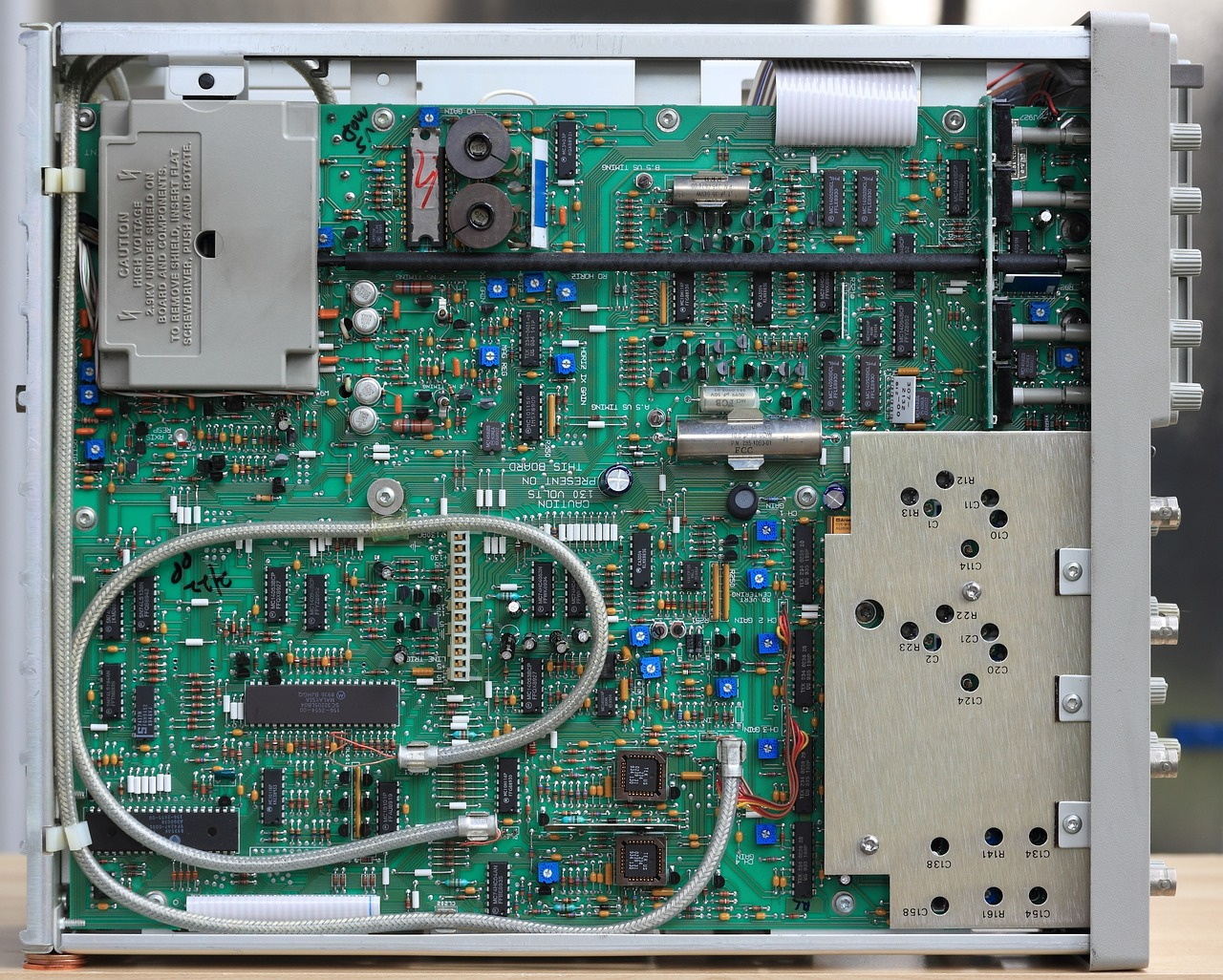

LPI solder mask stands for liquid photo-imageable solder mask. It's a protective layer attached to a PCB's surface (Printed Circuit Board). Although this layer usually looks green, it can be in different colors if you want color diversity. The primary job of the LPI solder mask is to protect the copper wires and important parts inside the PCB from things like moisture and dust. It also helps prevent gaps in the PCB assembly process.

And this LPI mask is essential for making circuit boards. It helps the electronic circuits work well and last a long time by preventing problems like short circuits and rust. So, it is an important part that helps maintain the integrity of the PCB's design and electrical connections.

Understanding the Basics

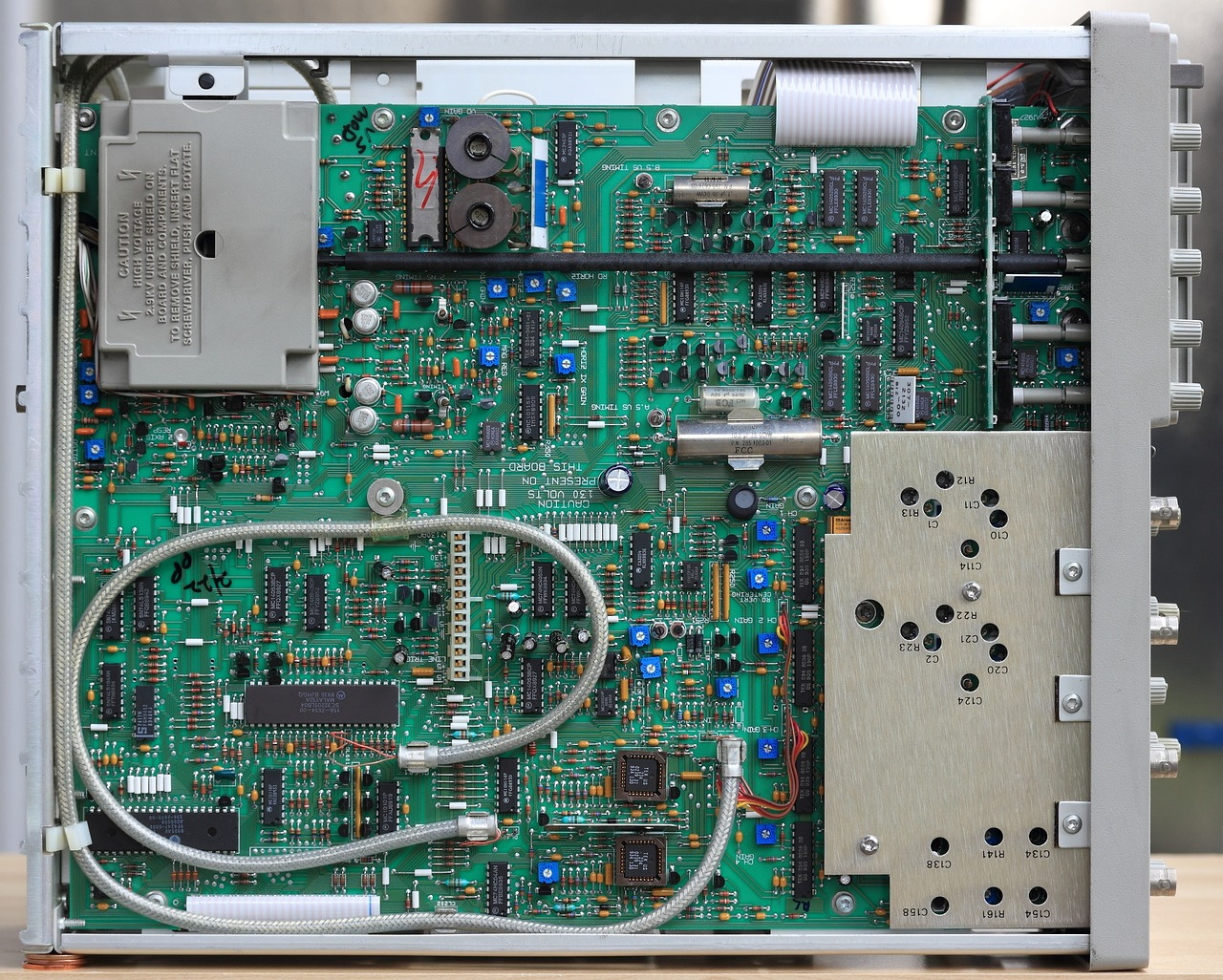

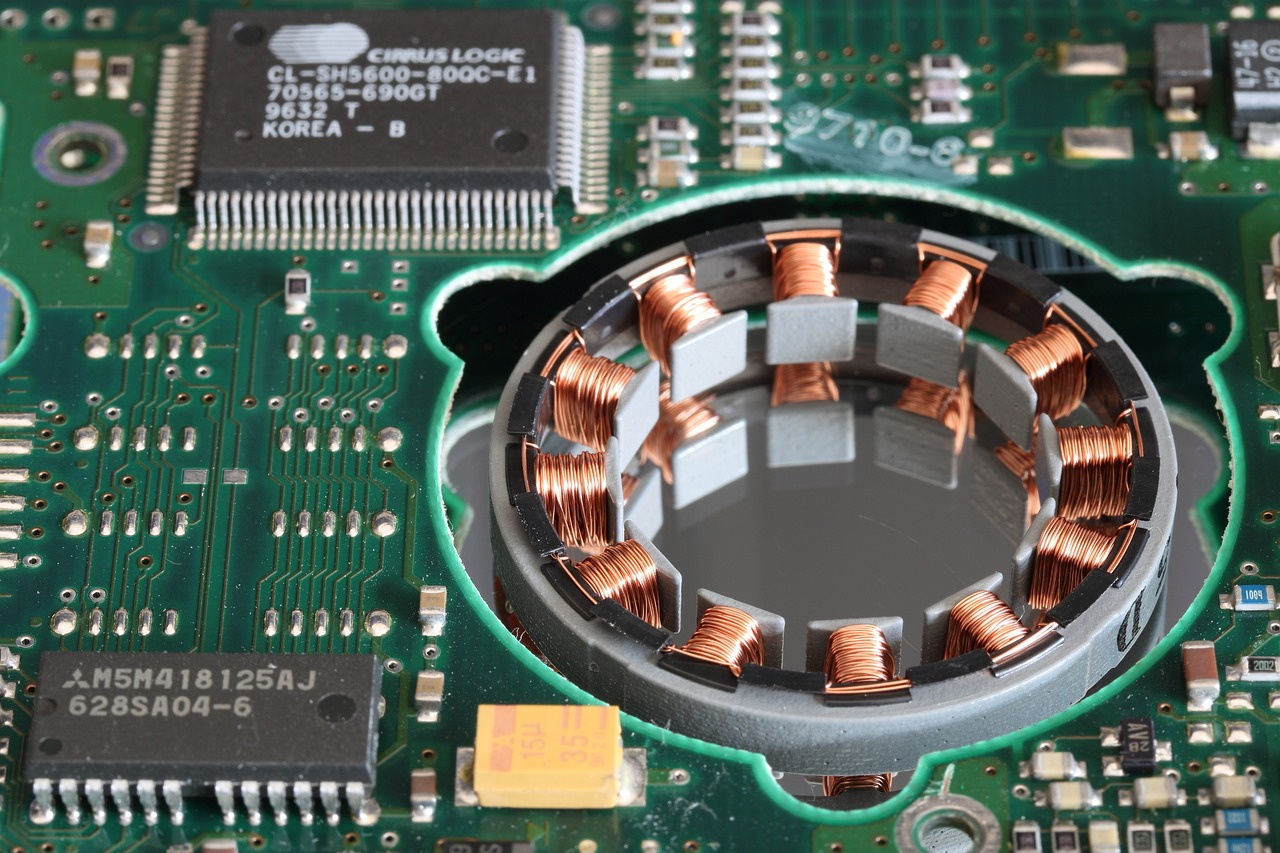

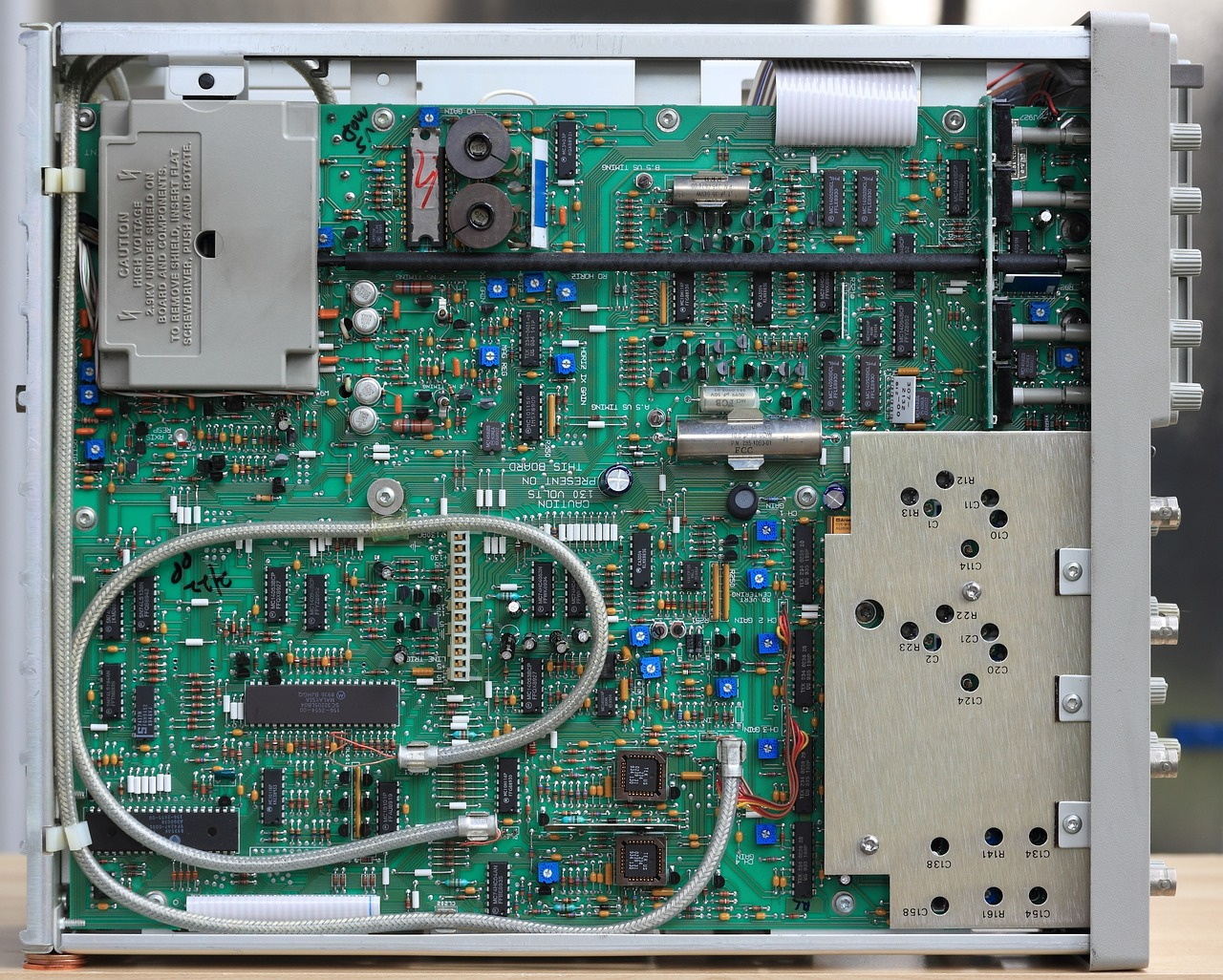

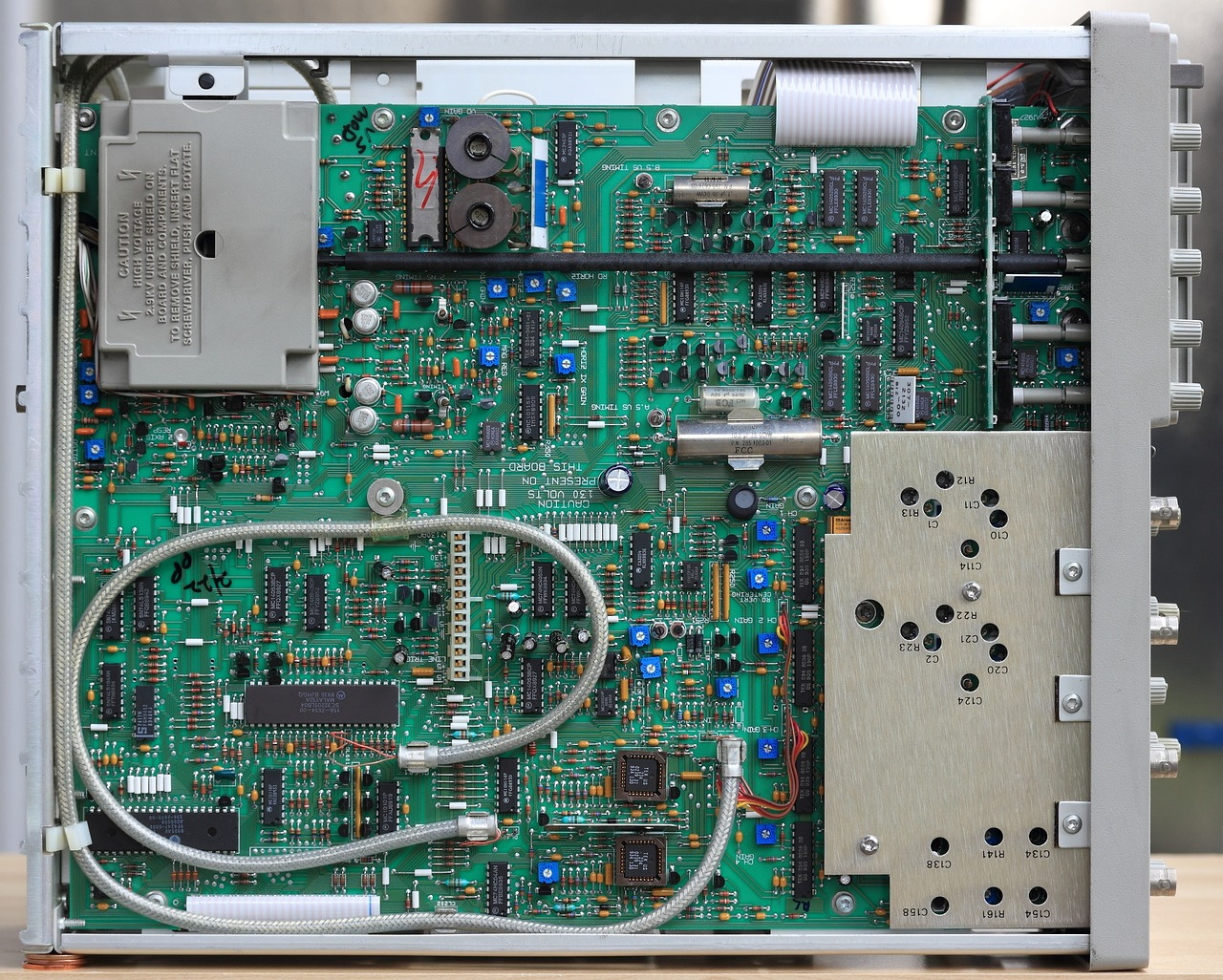

Before discussing the importance of LPI solder masks, let's start with the PCB basics. A PCB (Printed Circuit Board) is like the backbone of any electronic device. It's like a canvas or board with interconnected electronic parts to do a specific job. Creating PCBs requires careful attention to detail. This is where the LPI solder mask is usually used.

Advantages of LPI Solder Mask

The Protective Shield

Imagine a circuit board without any protective layer on it. The delicate parts are vulnerable to certain elements like damage, rust, and electrical malfunctions. Typically, the LPI solder mask is used for such protection. It's a thin layer of a special material that covers the copper traces and wires, keeping them safe from the surroundings.

Precision and Perfection of LPI Mask

So, the true beauty of an LPI solder mask is in its precision. Manufacturers apply it very precisely. Plus, they ensure it only covers the specific areas where things will plan, leaving the rest of the printed circuit board uncovered for placing and soldering components. Precision and perfection are important to avoid mistakes and ensure the circuit lasts long.

Color-Coding and Aesthetics

The primary purpose of it is to provide security for PCBs. Additionally, it adds aesthetic appeal. Manufacturers offer a variety of colors, allowing engineers to not only check and secure their designs but also make them visually appealing. This color-coding helps quickly identify and solve problems during assembly and maintenance.

Enabling Advanced Technologies

LPI solder masks have become even more critical and integral in smart, small, and complicated electronics. It allows for making complex circuit boards with multilayers with tightly packed parts. These advanced designs would be prone to short circuits and other electrical problems without this LPI mask protective layer.

How to Apply the LPI Solder Mask to a PCB Board

Applying a liquid photo-imageable solder mask to a printed circuit board involves several steps:

Step 1: Basic Preparation of the PCB

Before the patch is put on, the PCB goes through a few different steps to get ready. This involves cleaning and treating the surface of the PCB with chemicals or scraping. Or you can cover it in cleaning solutions.

Step 2: Application of Liquid Solder Mask

Producers apply the LPI solder mask all over the PCB like a liquid. Usually, they achieve it by screen printing, where they spread liquid coating evenly over the surface of the PCB and adjust the thickness of the layer on top of the patch.

Although application depends on LPI mask material, several methods exist for applying LPI solder masks, including screen printing, curtain coating, air spray, and electrostatic spray. The choice of method depends on the equipment available and the specific requirements of the PCB. Here's a general process for applying an LPI solder mask:

● In screen printing, manufacturers place a stencil with openings for the solder mask over the PCB, and the solder mask material is forced through the stencil onto the PCB surface using a squeegee.

● Another way that the manufacturer uses is air spray or spray coating with a spray nozzle. And the only loophole in this method is LPI mask wastage with multiple spray guns.

● In the electrostatic spray method, the ink is atomized within a rotating bell, and the LPI solder mask is drawn toward the circuit board due to its negative charge. However, it may cause a less uniform coating.

● The

curtain coating method involves flowing the solder mask material in a controlled curtain over the PCB's surface to ensure even coverage. Manufacturers consider it best for complex PCB fabrication.

Step 3: Exposure to UV Light

Once they attach the solder mask, they expose the circuit board to UV light. The UV light hardens the uncovered parts of the solder mask.

Step 4: Development

After UV light exposure, the manufacturer developed the PCB board. It removes the unnecessary solder mask and only keeps it where needed in certain areas. This creates openings for holes, vias, and pads, while a solder mask protects the remaining surface of the circuit board.

Step 5: Curing

After applying the LPI solder mask to the PCB, it goes through a curing process. This process makes the LPI mask even harder and ensures that it sticks well to the surface of the PCB.

Step 6: Inspection and Testing

Manufacturers do this quality control and inspection processes to ensure that the layer covering the solder is accurate, without any irregularities and defects.

Pro Tip: Always double-check the alignment of your paste layers with the copper and mask layers. This will help you highlight any openings or areas you should cover in the mask or stencil that are accurately represented in the paste layer. By doing this, you can prevent any mistakes or omissions that may affect the manufacturing process and the overall functionality of your boards.

LPI Solder Mask Colors

Liquid photo-imageable or LPI solder mask comes in a variety of colors. While green is the most common and traditional color, advancements in PCB manufacturing now allow for the use of different colors for both aesthetic appearance and functional reasons. Some of the most commonly used colors for LPI solder masks include:

Green

Green is a traditional color that manufacturers commonly utilize in the electronic industry. Particularly, manufacturers link it with PCBs as it's easily identifiable. During the final inspection, the green color also reduces eye strain.

Red

Another popular color option is red. We use a red solder mask to show certain parts or for aesthetic reasons.

White

White solder mask makes your circuit board look clean and smooth. However, it can be difficult to see parts when bright lights shine, although it works well with black silkscreens.

Black

Black is a good color for seeing things clearly because it contrasts well with other colors. However, if the lighting is not good, like if there are shadows, it could be challenging to see. A black circuit board is similar to a white one but stands out more and catches your attention.

Blue

Blue is a good color for putting LCD screens in place, and it looks nice compared to silkscreens. It may not be as fun as the other colors on the list, but it works well.

Yellow

Use a yellow solder mask instead if you want a special circuit board. This bright color makes it easy to see important parts.

Other Requirements for LPI Solder Mask

● LPI solder masks serve purposes beyond marking solderable areas on printed circuit boards.

● They undergo rigorous testing to meet IPC requirements. They must withstand processes and chemicals used in plating various surface finishes.

● LPI solder mask materials must pass a flammability test and receive a 94-V0 rating from UL.

● They come in various colors, with green being the most common, but other options like yellow, white, black, red, and blue are available.

● LEDs have influenced the market to develop more resilient white and black solder mask materials. PCB manufacturers highly prefer LPI solder masks.

The Final Word

LPI Solder Mask may not be the star of the show, but it's undoubtedly the unsung hero in the world of PCBs. From the idea to tangible parts, it is very important to ensure electronic device reliability. So, the next time you use a fancy gadget, remember that inside it is a carefully designed circuit board with a protective covering to keep its complicated parts safe.

Looking for a PCB or PCBA quote? Contact us now.