Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Low Volume PCB Assembly Made Easy with PCBasic

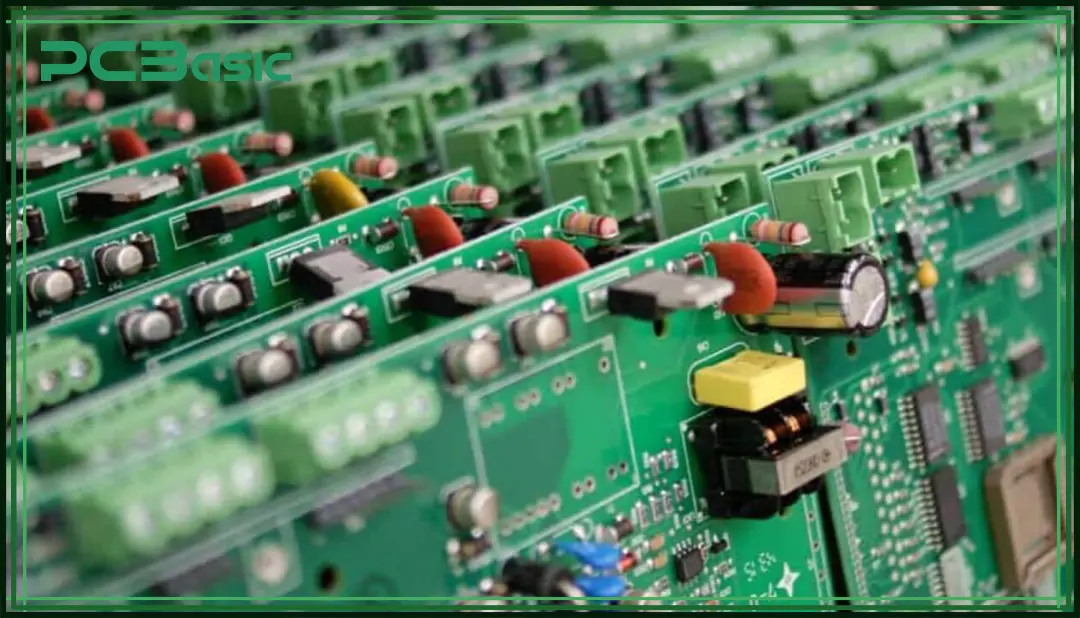

Are you familiar with the struggle to have your electronic prototype or small production run made? Welcome to the world of low-volume PCB assembly. This is where your innovative ideas meet precision, where your concepts turn into real electronic circuits. Just because you’re not seeking mass production doesn’t mean you have to settle for inferior quality.

Imagine that you are a start-up, a researcher, or an inventor with a wonderful concept of a groundbreaking electronic concept. Your level of vision may be small, but when applied, it can be substantial. This is where the low-volume PCB assembly is your ally. Patterns are more than a manufacturing process; they are the bridge between your mind and your vision.

Simply speaking, low-volume PCB assembly involves manufacturing a few printed circuit boards. Engineers know how to make perfect, functioning electronic platforms, not just a few boards. So, it is basically the sweet spot between prototyping and mass production.

Low volume circuit board assembly services typically mean making 10 to 500 circuit boards. This method is quite cool for:

1. Startup prototypes

2. Research & Development (R&D) projects

3. Custom Electronic Solutions

4. Reissues of limited-edition electronic products

5. Education; academic and scientific research

6. Niche-market for niche-market electronic devices

Low-volume PCB assembly is so flexible that it is beautiful. It enables innovators to experiment, refine, and hone their electronic designs without the need to invest millions in a large-scale production cycle. It is like a playground for technology creativity.

Looking at electronics manufacturing, when you start somewhere, there are some roadblocks. Consumers are quite correct that small-batch manufacturing can be problematic. Here are the main challenges below.

There are tremendous financial barriers in small-batch electronics manufacturing. With limited budgets, high setup costs can be prohibitive. Manufacturers generally engineer processes for mass production, which makes small runs expensive. When fixed costs are distributed over fewer units, each circuit board becomes expensive.

PCB assemblers favor high-volume orders. Within low-volume projects, you depend more on accurate component sourcing and specialized manufacturing requirements. Due to technical limitations, manufacturers capable of producing in smaller runs are harder to find. When only a few boards are being produced, monitoring their quality becomes trickier.

Low-volume PCB assembly often has longer production timelines than bulk orders. Smaller initiatives fall by the wayside, leading to a delay in prototype production. That affects research, startups, and product development timetables.

These challenges should not alarm you. The trick is to locate manufacturers who understand low-volume production requirements. Seek out partners who will work in smaller batches, offer flexible pricing, and give customized service. From some technology that is still going on, a promising path of small electronic innovation begins.

At the same time, PCBasic comes as pcb assembly manufacturer with boundless potential. You might have noticed this point: They make low-volume PCB assembly smooth and low-cost.

What makes them different? So the crux is how they approach PCB assembly services:

1. Flex manufacturer's option on distinct stage measures

2. Competitive pricing policies for urgent orders

3. Fast turnaround times that adhere to project timelines

4. High-quality standards with rigorous quality control

5. Complete assembly service from design through delivery

6. Tailored assistance for the complex and idiosyncratic

PCBasic treats each circuit board as a potential breakthrough, not just a component. It's a possible answer to a problem, an innovation yet to be achieved. Their method turns the hurdles of low-volume production into the strengths of precision and perfection.

Of course, it is clear that selecting the right PCB assembly manufacturer is important. Why does it matter? Quality and reliability are keys to the success of your project.

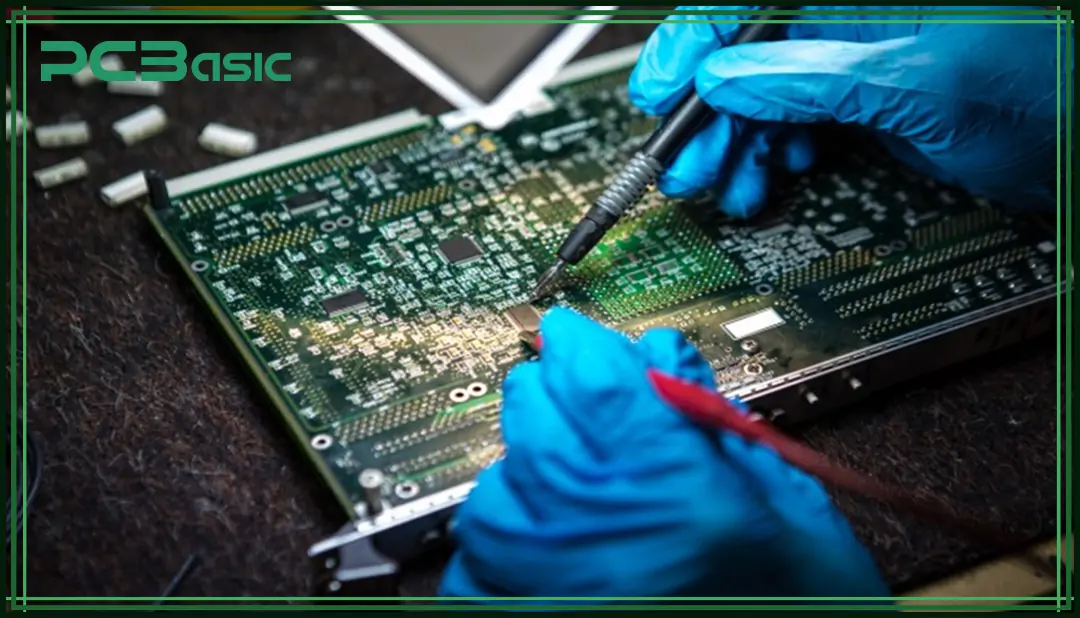

With state-of-the-art equipment, PCBasic boasts CNC machining shops that are far more advanced than most. This is not just about nice machines. This is about precision engineering. Secure state-of-the-art technology for highly accurate manufacturing that makes complex designs possible. At the same time, they also are investing in state-of-the-art manufacturing technologies that push the state of the art with respect to electronic board assembly.

The company's seasoned electronic board assembly crews add a unique and special touch to this process. Prototype PCB assembly isn't a one-size-fits-all process, and engineers know that. PCBasic has comprehensive know-how in a variety of industries, including medical devices, automotive electronics, IoT solutions, and consumer technology. This experience means they can take on wide-ranging and innovative design challenges that might give other manufacturers the heebie-jeebies.

PCBasic really shines in personalized customer support. This clearly shows that they are doing much more than just making circuit boards. This includes transparent communication, rigorous project tracking, and a deep understanding of each client's specific needs. Why does it matter? Because they're doing more than manufacturing circuit boards—they're collaborating in innovation.

It is crucial to this point that PCBasic understands that each circuit board has a story to tell about innovation. Whether you are developing a medical device, Internet of Things solution, automotive electronics, or new consumer product, PCBasic has the knowledge and experience to help you create it.

Don’t get distracted; focusing on your project's requirements would be the best you can do. With electronics assembly services, every detail matters. Our PCB assembly services, including low-volume PCB assembly, will ensure that.

Be kind to your prototyping process. Design spontaneously. Pay attention to what makes your electronic products unique. Remember that great innovative ideas begin with a small concept yet have a great impact on a large market.

Are you ready to turn your electronic dreams into a reality? PCBasic is your partner in low-volume PCB assembly, bridging the divide between your innovative idea and a product that can be sold.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.