Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBasic: Your High-Volume PCB Assembly Manufacturer

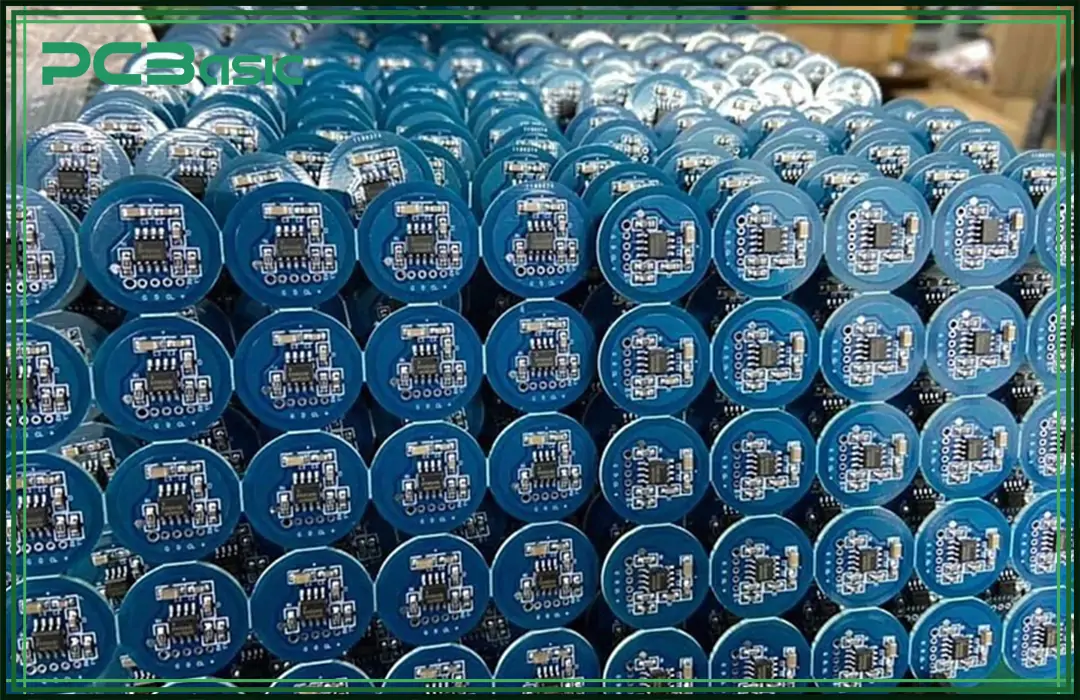

Admittedly, the foundation of every successful electronic device begins with a perfect printed circuit board assembly. That's where PCBasic comes in. We are a trusted high-volume PCB assembly manufacturer with one-stop solutions that seamlessly scale up for large production needs.

Our team operates advanced automated processes to enable precise and consistent production on a large scale. In this guide, we'll explore the basics of high-volume PCB assembly, its challenges and how PCBasic stands out with flexible and innovative solutions.

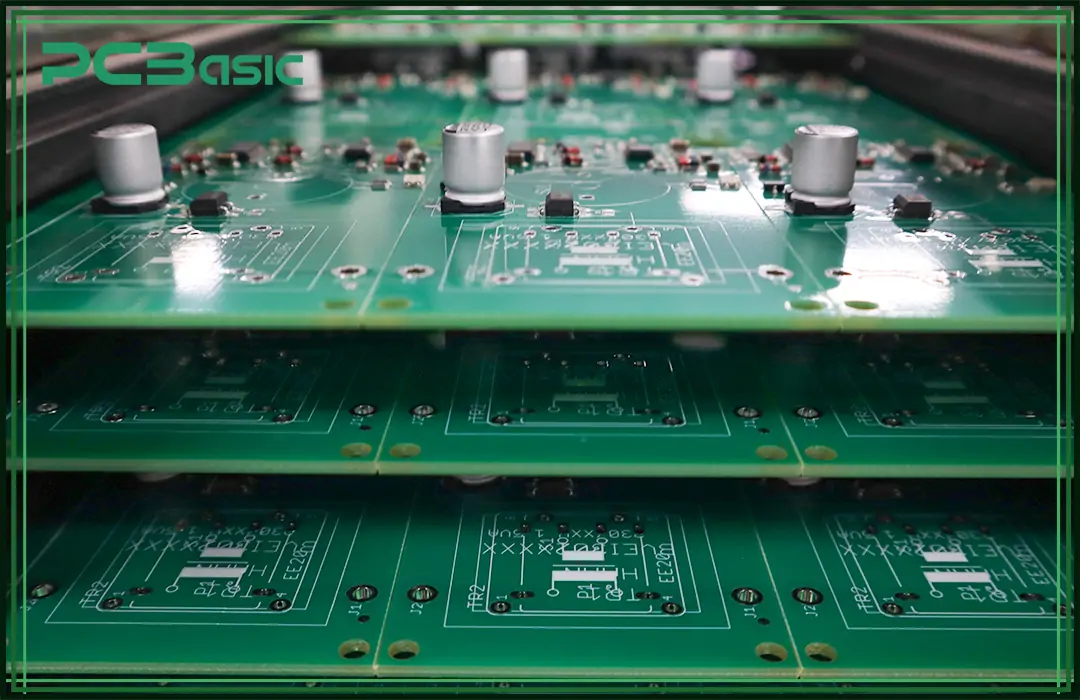

The process of manufacturing large quantities of printed circuit boards (PCBs) through automated production methods is called high-volume PCB assembly.

Industries that need PCBs at scale to meet the increasing market demands typically rely on this method while maintaining rigorous quality control protocols.

The main objective of high-volume PCB assembly consists of delivering numerous high-quality PCBs while minimizing production expenses. Some key benefits include:

● Manufacturing bulk products reduces production costs since it utilizes the economic advantages of large-scale production.

● The use of automation allows manufacturers to assemble products more quickly, thus decreasing production time.

● Every product undergoes superior quality checks through advanced testing features, which maintain industry standard compliance for each printed circuit board.

● High-volume manufacturers use standardized processes to minimize defects and enhance product durability.

The method remains vital for businesses requiring constant supply and production efficiency because it helps products reach consumers quickly while maintaining quality standards.

Manufacturers who want to reach optimal outcomes adopt multiple best practices, including:

● Design for Manufacturability (DFM): This method guarantees PCB designs achieve maximum effectiveness during mass production.

● Implement Automated Testing: Manufacturers implement Automated Optical Inspection (AOI) and In-Circuit Testing (ICT) to detect defects early during production.

● Maintain Supplier Relationships: Maintaining an uninterrupted supply of high-quality components to prevent manufacturing delays.

● Monitor Production Metrics: Implementing strict protocols to guarantee uniformity of all PCB units.

High-volume PCB manufacturing is a complex process since it requires precise execution, effective management, and strategic planning. While this method is cost-effective and offers scalability, it is not free from challenges.

Here are some of the challenges in high-volume, quick-turn PCB assembly manufacturing.

The steady availability of high-quality electronic components plays an essential role to maintain continuous production. The use of insufficient parts, delayed delivery service, and counterfeit components leads to product performance problems while creating financial burdens and operational delays.

Solution: Reliable partnerships and effective supply chain management reduce the potential risks faced by high-volume electronic PCB assembly manufacturers.

In high-volume PCB robotics assembly manufacturing, maintaining quality is a daunting task. The production of thousands or millions of PCBs becomes vulnerable to significant financial losses when any defect occurs.

Solution: High-volume PCB requires strict quality control measures, including Automated Optical Inspection (AOI), X-ray testing and In-Circuit Testing (ICT) to identify flaws early and maintain consistency throughout stages of production.

Mass production becomes less efficient when PCB designs lack proper optimization. PCB assembly failures occur due to design errors that include incorrect trace configurations, insufficient component spacing and improper board component positions.

Solution: Implementing DFM principles enables more efficient production while decreasing operational mistakes.

High-volume manufacturing minimizes unit costs. However, increased material prices, labor expenses, and equipment maintenance costs can affect profitability. Manufacturers need to find ways to minimize costs while maintaining product quality standards.

Solution: Streamline your supply chain, automate processes, and buy in bulk to keep costs low without sacrificing quality.

The electronics industry is growing rapidly. This allows manufacturers to purchase modern equipment, automate their operations, and train personnel for advanced PCB technologies.

Solution: Maintaining modernization in this field remains vital to stay competitive in the market.

The effective resolution of these challenges leads to a production method that provides cost efficiency, high quality, and smooth operation.

PCBasic is a leading high-volume PCB assembly manufacturer that provides precise and high-quality services along with complete assembly solutions. With over a decade of experience, we specialize in offering comprehensive solutions for all PCB assembly requirements.

You can count on us for many reasons, including:

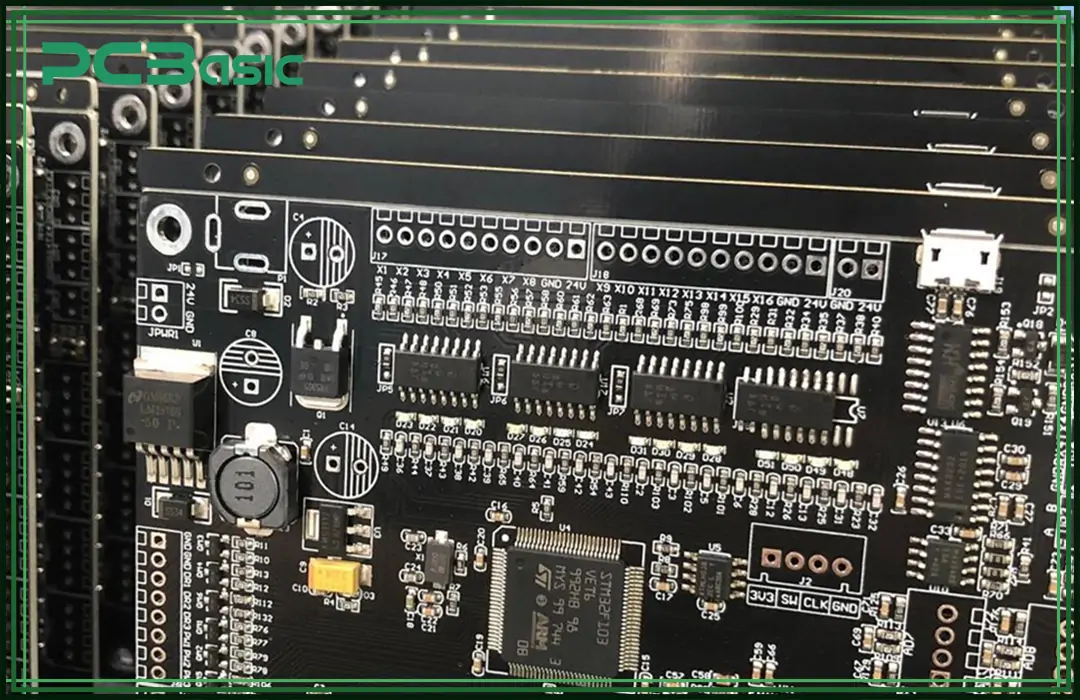

● Advanced Manufacturing Technology: We utilize cutting-edge technology to perform quick and precise large-scale PCB assembly operations.

● 10+ Years of Expertise: Our company possesses more than ten years of expertise, which allows us to understand complex mass PCB production needs and deliver exceptional quality.

● Strict Quality Testing: We prioritize quality control and comply with ISO9001, IATF16949, and ISO13485 standards. Besides, we utilize advanced inspection techniques to ensure reliability and performance.

● Cost-Effective Solutions: Our production method delivers effective cost reduction through streamlined operations that maintain superior quality standards.

● 24/7 Customer Support: We maintain a 24/7 customer support system to provide continuous assistance for technical issues, order management and inquiries.

PCBasic provides adaptable and flexible solutions for high-volume PCB assembly because we recognize that each project has specific requirements. From design modifications to customized production runs and specialized testing, we cater to your needs.

Our dedicated team collaborates with clients for optimizing PCB layouts with performance-based design while ensuring manufacturability and cost optimization.

Our company enables customers to request custom specifications that include multilayer PCBs, rigid-flex design capabilities and high-density interconnect (HDI) boards.

Whether it's small pilot runs or full-scale mass production, PCBasic ensures smooth scaling without compromising quality. Our advanced top-notch equipment handles high volumes without losing accuracy and measurable stability across the board.

When you choose PCBasic for high-volume PCB assembly, your business acquires quality, efficiency, and reliability. Our compression solutions and smart automation systems enable production growth without sacrificing quality standards.

PCBasic provides your business with the power to deliver precise solutions at high speed for market needs.

Contact our team right now to witness the industry-leading commitment at PCBasic, which delivers your business success. You can reach us at any time to enhance your manufacturing processes.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.