Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Flying Probe vs ICT: A Comprehensive Comparison

Testing is the key in the electronic boards and PCB assembly so as to confirm the board works as intended. There are two testing methods which are the most popular— flying probe testing and in-circuit testing, and the ultimate purpose of them is the same — find faults and check the quality of circuit board assemblies.

But there are some advantages, disadvantages to the approaches, as well as use cases for one over the other. Flying probe vs ICT testing – in this blog post, we will take a look into flying probe vs ICT and their characteristics, advantages and disadvantages of each test method and how to select one for your needs to achieve cost-effective circuit testing.

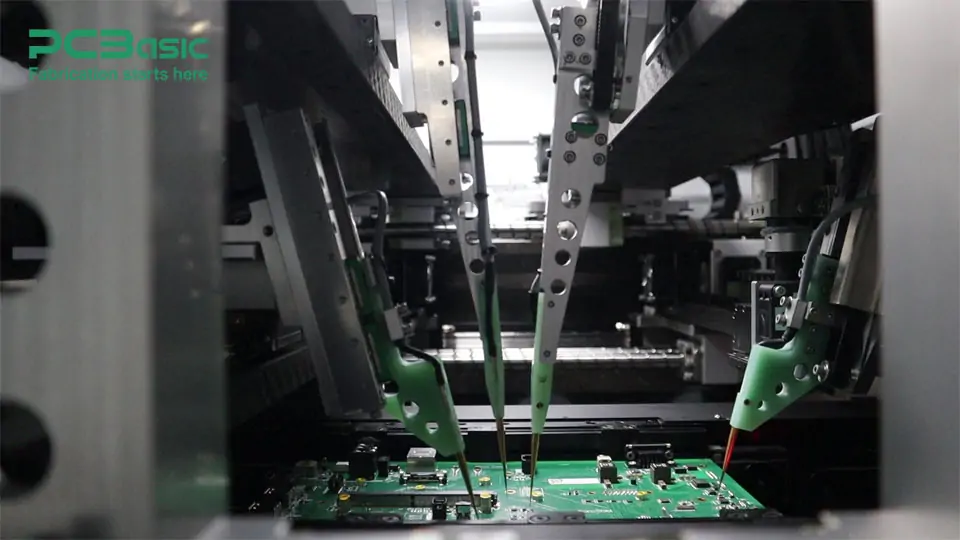

In PCB, flying probe testing is a non-contact testing method for electronic boards that can test open circuit, short circuit, component orientation and other problems in electronic located in the circuit board, especially, for SMD components. In this method, a flying probe machine tests the connection by contacting test points on the test area of a circuit board with a series of test probes.

A software program in the flying probe tester controls the motion of the probes and the test points to be tested. This method is generally used in prototype or low-volume situation because it may be not cost-effective to build dedicated test fixtures for ICT testing.

Flying probe testing has several points that stand out compared to ICT testing.

1. Cost-Effective for Low Volumes

Flying probe testing can be used for small series production and prototype boards as it is much more cost-effective than ICT testing since there is no need to create a dedicated test fixture. In the case with a flying probe testing machine, the probe is programmed to move to its destination and it will not use test fixtures.

2. Flexibility

In comparison to ICT testing, which depends on static test points and the use of specially built test fixtures, flying probe testing offers a high degree of versatility. Another advantage is that the flying probe tester can be reprogrammed quickly and can test different circuit board dimensions or electronic boards, which makes it more convenient during rapid changes and adjustments.

3. No Need for Bed Nails

Contrary to ICT testing, flying probe testing does not require the installation of bed nails which may injure sensitive components especially if they are misaligned, as in the case of ICT testing. Flying probe testing minimizes the risk of damage to the SMD components as the components are not touched, which is ideal when testing SMD components, especially smaller solutions.

4. Ideal for Complex or Custom Circuits

Flying probe testing is better adapted to test point changes than ICT testing, so are more suitable for complex or custom circuit board assemblies. It can be more easily adjusted to any circuit design because it does not depend on fixed test points.

Despite the advantages of flying probe testing, there are some shortcomings.

1. Slower Testing Process

Although flying probe testing has a cost advantage for low-volume production, it is slower to test when compared to ICT testing. This is a time-consuming process for testing large boards or boards with more test points because the probes have to be moved to each test point one at a time.

2. Limited for High-Volume Production

One of the major drawbacks of flying probe testing is it is not the ideal candidate for high-batch PCB assembly. The testing time of each electronic board is time-consuming, and if we have to do it with large batches, it is not cost-efficient.

3. Not Suitable for Some Components

Flying probe testing can check most of the test points, but for components which have dedicated test procedures such as capacitors or resistors, flying probe testing may not be an option. In such instances, ICT testing could be a more suitable option.

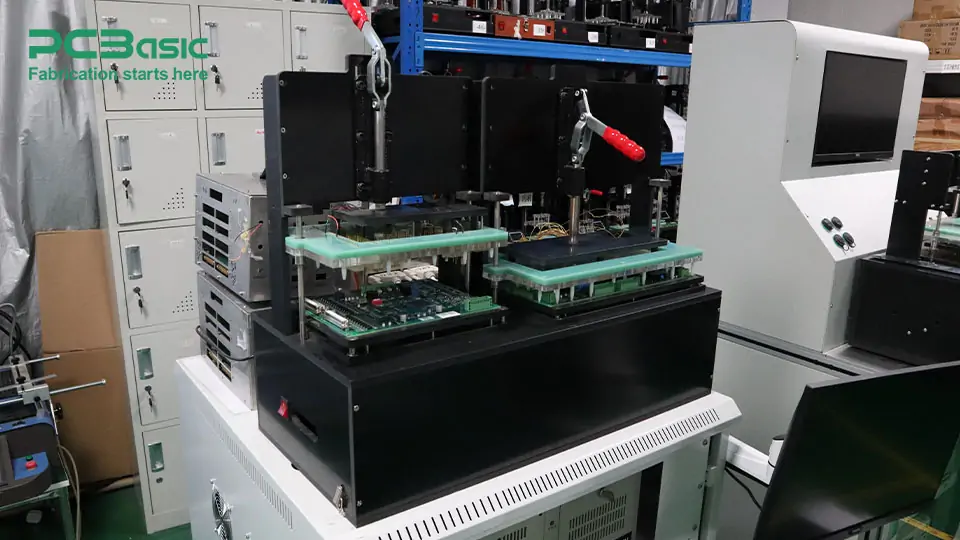

In-circuit testing (ICT) is a common test method, testing the circuit board assembly by sensing each of the components on the board as well as the connections of the board components, like SMD components, resistors, capacitors, and so on. ICT testing is performed by placing the circuit board on a board nail, connecting the test point on the board, applying a voltage to the circuit and measuring results to determine whether there is a short circuit, open circuit and component good or not.

In-circuit testing has its unique advantages.

1. Faster and More Efficient for High Volumes

In comparison with flying probe testing, ICT testing is faster because in ICT testing, it uses fixed test fixtures and bed nails. And by the way, and it can perform parallel testing on many points of the circuit board at the same time. This makes ICT testing perfect for high-volume PCB assembly.

2. Thorough and Comprehensive Testing

ICT testing is a very comprehensive check which tests all SMD components mounted on the PCB and pacifies that all connections and soldered components are in the right position and functions. It is also able to verify circuit elements like capacitor orientation, resistor values, etc.

3. Automated Testing

After the test fixture is set, essentially, ICT testing could be fully automated with minimal human intervention. This is perfect for mass production as it ensures consistency and repeatability of the test results.

Like flying probe testing, ICT testing has outstanding advantages, but it also has disadvantages that cannot be ignored.

1. Expensive Setup

One of the biggest downsides of ICT testing is the expense of the test fixture. This could be an expensive and time-consuming process because bed nails and test fixtures must be tailored to each circuit board design. This renders ICT testing less appropriate in the case of small series production or prototypes.

ICT testing is not as flexible compared to flying probe testing. After the test fixture is set up, it becomes a very arduous and expensive process to change. Flying probe testing may be more applicable for custom or complex electronic boards.

3. Damage to Sensitive Components

However, using the bed nail for ICT testing could damage sensitive elements or SMD components if the pneumatic position is not accurate. On the other hand, flying probe testing eliminates the risk of damaging the PCB assembly by using a non-contact probe,

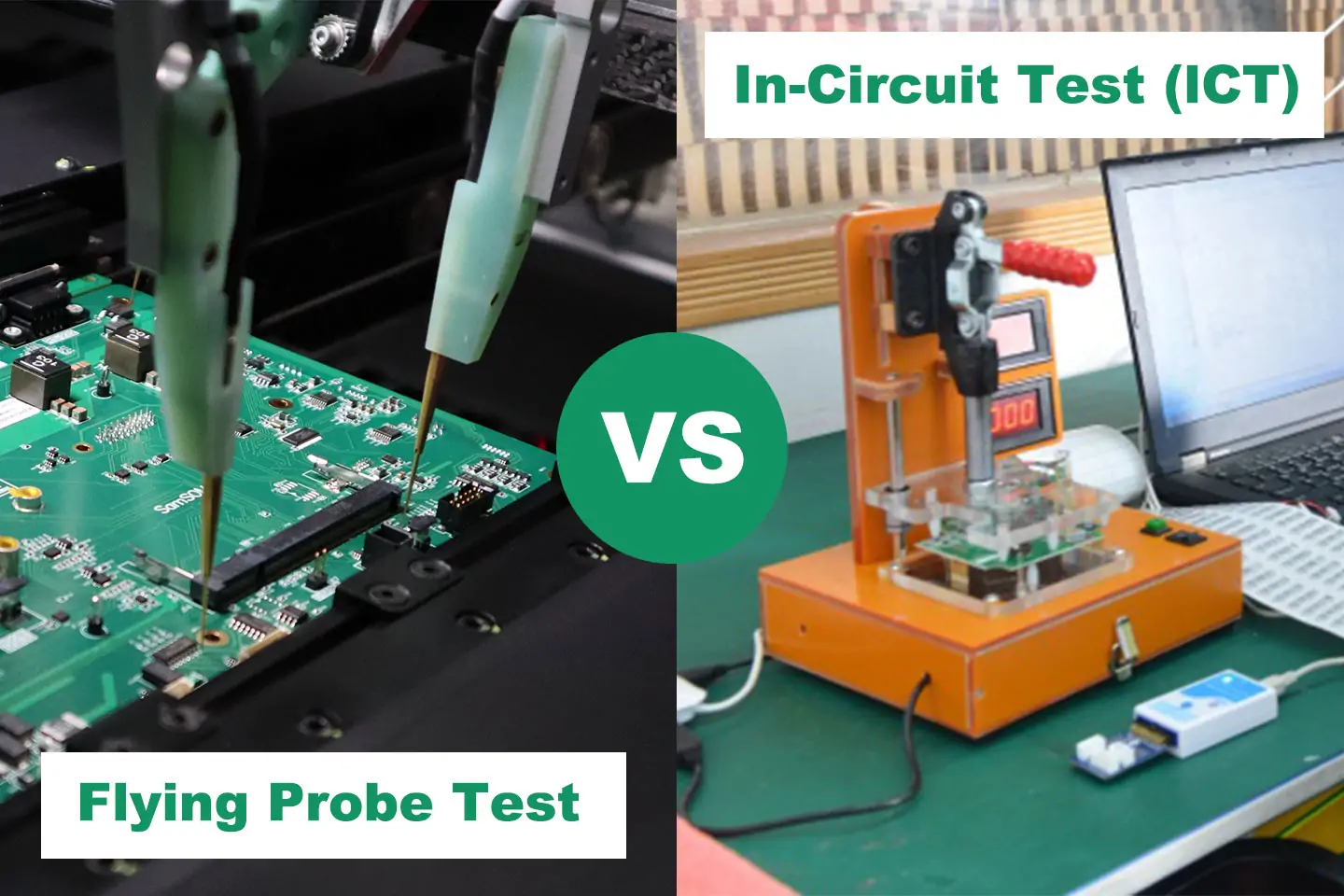

We have already learned about in detail that what flying probe testing is and what ICT testing is, so what are the differences between them? Let's compare them comprehensively in a chart.

|

Feature |

Flying Probe Testing |

In-Circuit Testing (ICT) |

|

Cost |

More cost-effective for low-volume runs |

Expensive due to test fixture setup |

|

Speed |

Slower, more time-consuming |

Faster, ideal for high-volume production |

|

Flexibility |

Highly flexible, easily reprogrammed |

Limited flexibility, fixed test fixture |

|

Testing Coverage |

Limited test points, less thorough |

Comprehensive testing of all components and connections |

|

Suitability for Prototypes |

Ideal for prototypes and small batches |

Not suitable for prototypes due to high setup costs |

|

Risk of Damage |

No risk of damage to components |

Risk of damage to SMD components from bed nails |

|

Best Use Case |

Low-volume, custom boards, quick turnarounds |

High-volume PCB assembly, mass production runs |

When flying probe vs ICT testing is concerned, one method to prefer over another entirely depends upon production requirements and specific needs of the PCB assembly. For low-volume production boards, prototype boards, or even custom electronic boards, flying probe testing is an ideal, cost-effective, and flexible solution. Alternatively, if you are in a mass-production environment and require speed and maximum test coverage, then ICT testing will be your best bet, as it will offer a faster, automated testing solution which is capable of full coverage of the board.

In summary, both two methods play an important role in the functional testing of circuits and PCB assembly, and both of them offer specific benefits in specific situations. The choice depends on the production volume, cost-effectiveness, and complexity of the circuit board assemblies. What are flying probe testing and ICT testing? Knowing what flying probe testing and ICT testing are will help you make the ideal decision for your testing requirements.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.