Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCBasic: Your Trusted Partner for BGA Prototype PCB Assembly

In the rapidly evolving electronics industry, BGA technology plays a vital role in modern PCB design and assembly. Whether in consumer electronics, medical devices or industrial applications, successful BGA assembly is the key to ensuring the performance and reliability of equipment. However, the assembly process of BGA circuit boards is more complex, requiring advanced equipment and precision processes.

With more than 10 years of PCB assembly manufacturing experience, PCBasic is a trusted BGA prototype PCB assembly partner. With cutting-edge assembly equipment, a strong supply chain and an experienced engineering team, PCBasic is able to provide customers with flexible and cost-effective PCB assembly services to meet their production needs.

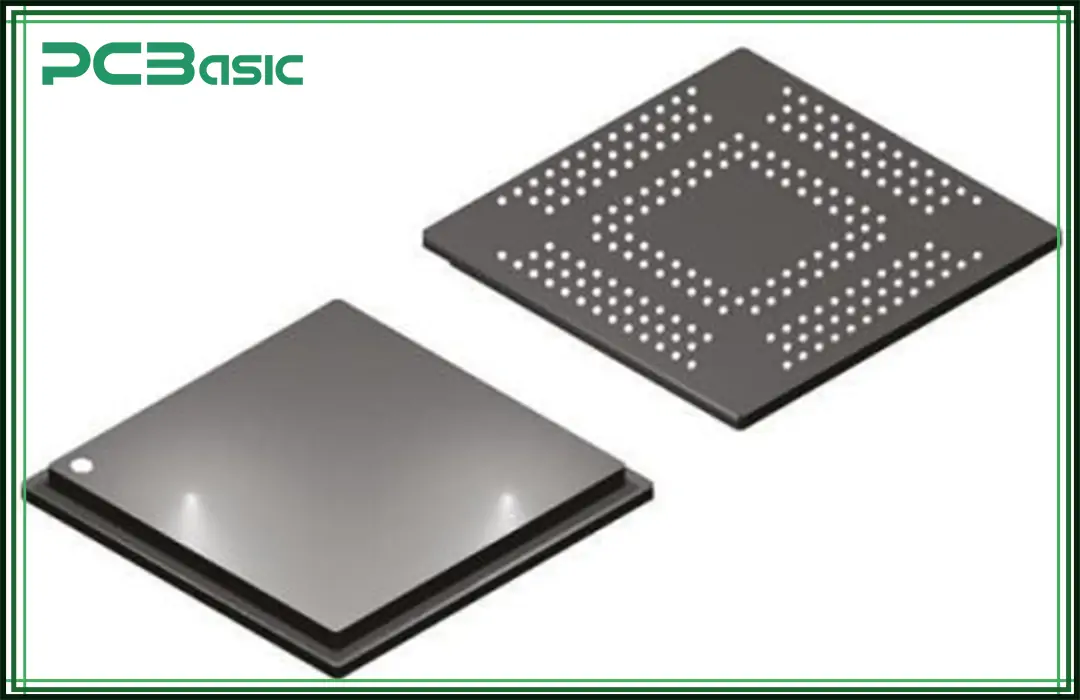

Ball Grid Array (BGA) package technology offers higher connection density, better electrical performance, and more efficient thermal management than traditional pin-based components. Traditional pin-based packages, such as DIP and QFP, rely on pins around the component to establish electrical connections. The BGA package is directly connected to the pad on the PCB through a uniform array of balls on the bottom of the chip. This design not only reduces the limit of pin spacing, improves the connection density, but also effectively shortens the signal transmission path and improves the integrity of high-speed signals.

In addition, the thermal performance of the BGA package is far better than that of the traditional package. Because the solder ball is in direct contact with the PCB pad, the heat inside the chip can be conducted to the PCB more efficiently through the solder joints. This design significantly reduces the risk of performance degradation or failure due to overheating.

• Compact Design: Ideal for high-density circuits.

• Improved Performance: Enhanced electrical and thermal properties.

• Reliability: Robust connections that withstand mechanical stress.

Although BGA assembly has significant technical advantages, it also faces many unique challenges in the assembly process, mainly in the aspects of solder quality control, mechanical stability and manufacturing accuracy.

1. Hidden Solder Joints--High Inspection Difficulty, Reliance on X-ray Detection

The solder balls of BGA packages are all located at the bottom of the package, in direct contact with the PCB pad and soldered. This design brings challenges in soldering quality detection. Because solder balls are completely hidden and cannot be inspected by conventional visual inspection or probe testing, non-destructive testing techniques, such as X-ray inspection, are relied upon to assess the integrity of solder joints and determine whether there are defects such as cold solder joints, voids, solder ball fractures, or short circuits.

2. Warpage Issues--Impact on Soldering Reliability, Risk of "Head-in-Pillow" Defects

BGA packages usually use thinner substrate materials. In the reflow soldering process, affected by temperature changes, the coefficient of thermal expansion (CTE) of the BGA package and the PCB may be different, resulting in package warpage. This can affect the long-term reliability of the circuit board. In order to reduce the risk of warpage, it is essential to optimize the soldering temperature profile, use fixture clamps, or select low-warpage BGA packaging materials to ensure high-quality soldering.

3. Precision Requirements--Accurate Component Placement and Reflow Soldering are Critical

BGA assembly requires very high component mounting accuracy and reflow soldering process. If the BGA package is aligned when mounted, it can lead to solder failure or solder bridging, which can affect the performance of the board. Therefore, precise pick-and-place machines, fine soldering process control, and strict temperature curve management are key to ensuring the quality of BGA soldering.

These challenges highlight the need for expertise and advanced equipment in BGA prototype PCB assembly.

PCBasic specializes in overcoming these challenges through innovative processes and state-of-the-art technology.

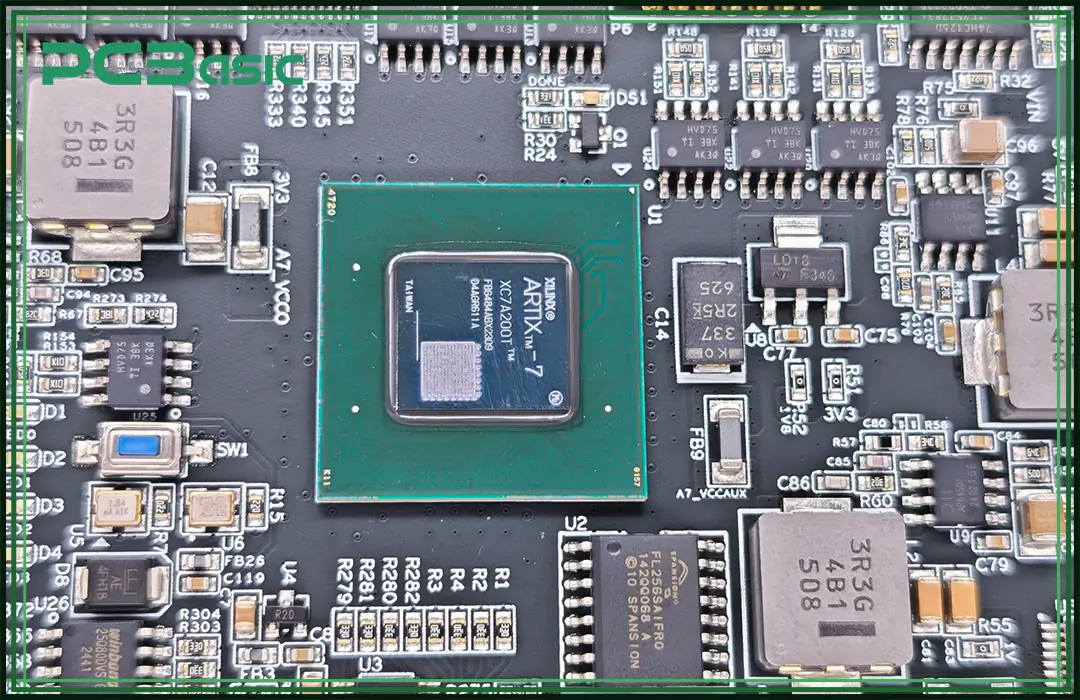

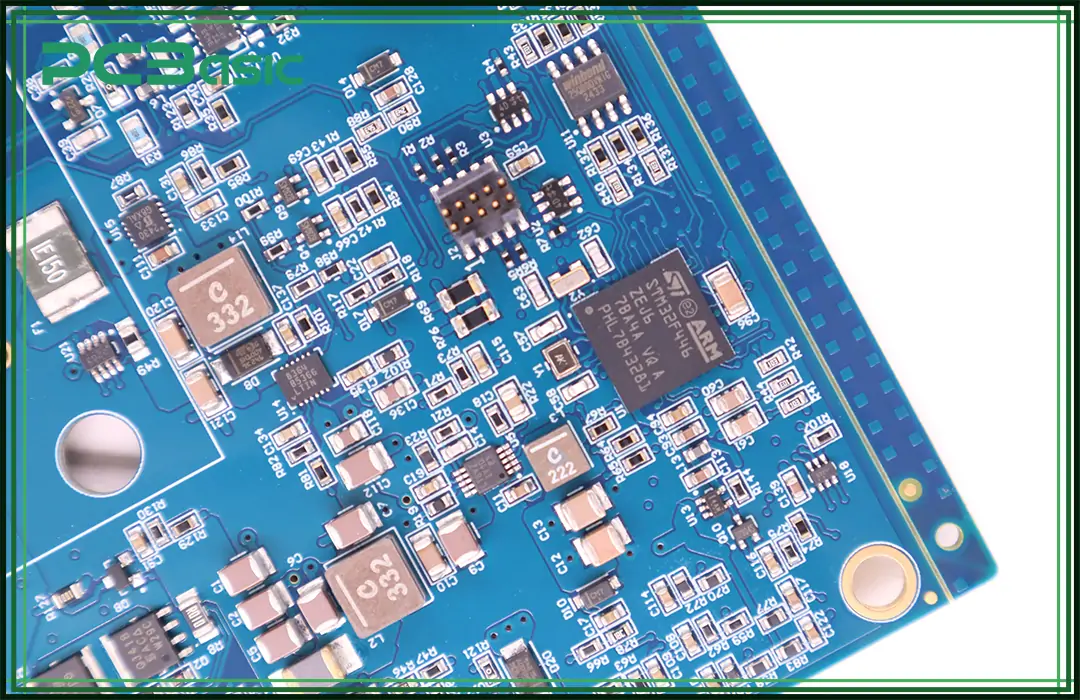

PCBasic employsadvanced Ball Grid Array soldering techniques, ensuring reliable BGA assembly with precise temperature control and minimal defects. Its high-tech assembly equipment like automated pick-and-place machines supports leaded and lead-free BGA packages, guaranteeing compliance with international quality standards.

Since traditional inspection methods cannot effectively assess BGA electronics, PCBasic utilizes X-ray inspection technology for detecting hidden solder joint defects. Additionally, it uses automated optical inspection (AOI) to identify alignment and placement errors. Besides those, PCBasic has functional testing to verify electrical performance before delivery.

By the way, PCBasic is an ISO13485, IATF 16949, ISO9001, and IPC-certified PCB assembler, ensuring that every BGA circuit board meets stringent quality requirements.

PCBasic is concerned about the importance of quick turnaround times for prototype PCB assembly. With its Shenzhen-based small-batch factory, it delivers rapid PCB assembly services while maintaining high precision and reliability.

PCBasic provides a robust supply chain with guaranteed sourcing of original and genuine parts. Its intelligent electronic components central warehouse ensures that all materials used in BGA assembly are of the highest quality. It prevents counterfeit or defective components from affecting product’s performance.

Additionally, its one-click BOM import system and instant quoting system allow for seamless order processing, ensuring an efficient turnkey PCB assembly experience.

With over 10+ years of PCB design and project management experience, PCBasic stands out as a leader in BGA prototype PCB assembly.

• Collaboration with PhD teams from multiple universities for cutting-edge research.

• Multiple manufacturing facilities – small-batch production in Shenzhen, large-scale production in Huizhou.

• Self-operated stencil and fixture factory, allowing for rapid stencil production within 1 hour.

• CNC precision parts processing for high-accuracy PCB assembly.

• Certified quality management – ISO13485, IATF 16949, ISO9001, and UL certifications.

• Over 20 patents in quality inspection and production management.

By partnering with PCBasic, you gain access to state-of-the-art BGA assembly, world-class PCB assembly manufacturing, and a seamless turnkey PCB assembly process.

In the competitive electronics industry, choosing the right PCB assembler for your BGA prototype PCB assembly is crucial. With PCBasic, you get cutting-edge BGA technology, advanced Ball Grid Array soldering, and a reliable PCB assembly service designed for high performance and quality.

Whether you need prototype PCB assembly or mass production, PCBasic is your trusted partner, delivering flexible, cost-effective, and high-quality PCB design and assembly solutions.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.