Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > The Ultimate Guide to the Best Solder for Circuit Boards

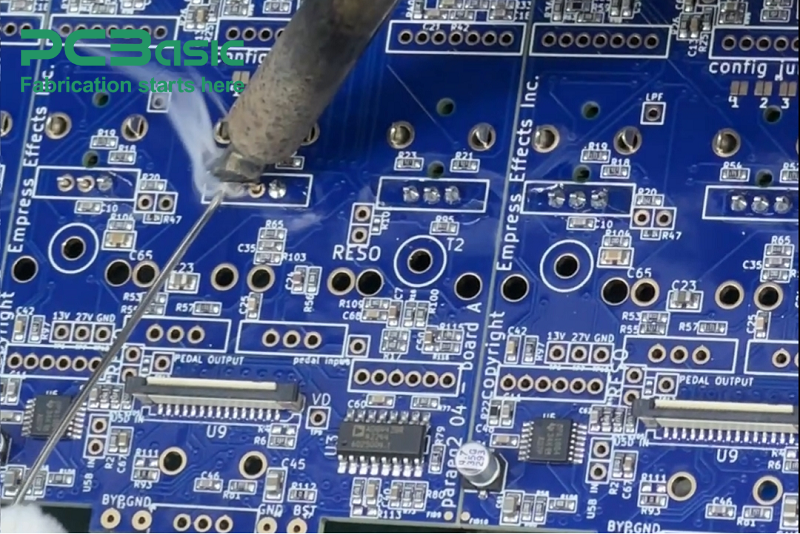

Whether you're just getting started with DIY electronics or are an engineer working on advanced systems, soldering is one important skill that you need to acquire. Simply put, soldering is a process of using a solder, which is an alloy, to join components and circuit boards together.

Solder comes in many types, making picking the most suitable one for your project hard, but it is of utmost importance as it can affect how well the project works, first and foremost, how durable it is, and whether it is safe to use.

So worry not; we have got you covered. Soldering might be a daunting task, but this guide will provide you with up-to-date information about the necessary tools needed and soldering tips to provide you with the best solder for circuit board results. By the end of this article you will acquire the skills to revolutionize your electronics projects. You won't need to give it another thought as you will be well-informed about how to solder and which solder to use.

Soldering is the going of the parts and melting solder around the place of connection of the soldered parts to form a strong mechanical bond together with conducting solder. In the case of solder, it operates whilst responding to the attachment of various components, such as resistors, capacitors, and integrated circuits, on the traces of conductive boards for stability and functionality purposes; soldering becomes essential.

The Role of Solder in Circuit Boards

A solder has a variety of functions on a circuit board. To begin with, solder provides a conductive path between various components, thus ensuring good electrical connections that are essential for the operation of the circuit. Moreover, solder serves as a mechanical bond whereby components are fixed even when there are vibrations or resistance shocks, such as occurring during soldering.

One more crucial function of the best solder for circuit boards is to serve as an anti-fouling agent by preventing the oxidation of the joints or connection areas of the joints of the circuit from being de-rated over time. A good selection of solder will considerably increase the life span and reliability of your circuit boards.

Tin-Lead Solder (SnPb)

Tin-Lead Solder which is almost 60 and 40:40 now 8% Lead and Tin has been enjoying the electronics arena for many decades. Tin-lead solder is still one of the most dominant solders in the industry because it is an excellent allowance to work with due to its great soldering abilities as well as ease of use, and the melting point is reasonably low. Unfortunately, the use of lead poses health and environmental risks; this is slowly evolving as concerns are raised and the use of lead is banned.

Lead-Free Solder

As the world becomes more aware of environmental implications and certain health issues to people, lead free solder has grown to become the new standard across every industry including consumer electronics for SnAgCu and tin copper solder, no longer using lead. In most cases, it is the SN head or lead, and the Solder is AgCu; such solder is benign to the environment. However, the melting point is rather high, which requires reliable temperature control equipment for the best solder for the circuit board.

Silver-Based Solder

Silver-based solder has proven to have a reasonably high melting point and usually needs a Solder. AgCu and SAC solder generally contain tin. Despite silver increasing the cost of the solder, the high melting point is comparable and allows using solder with low thermal and electric conductivity. By having these needles, the best solder for circuit boards can bring reliability and high performance to those who need it, such as military people and aerospace.

High-Temperature Solder

High-temperature solder is used in automotive or industrial electronics that require significant thermal stability. They have a higher melting point, which makes them suitable for very high-temperature applications. High-temperature solder guarantees that the joint will remain securely conductive even under the most adverse conditions.

There are ramifications to choosing between lead and lead-free solder, and as was already mentioned, this is a critical choice to make:

Composition: Commonly consists of 60 %tin and 40% lead (SnPb 60/40).

Melting Point: A lower melting point of about 183c makes it easy for other sessions.

Workability: Tends to flow more, which helps make tight and reliable joints.

Electrical Conductivity: Superb, as it assures decent electrical wiring.

Mechanical Strength: Connections are strong, and segments are mechanically sound.

Health and Environmental Impact: Lead is a toxic substance to humans and the environment, and lead-free solder is toxic to it. Severe health conditions, such as damage to nerves, can be caused after prolonged exposure to it.

Regulation: Any form of lead selling has been regulated due to its health problems, such as the RoHS Directive. It has made industries move on to use safer substitutes.

Composition: Tin, silver, and copper (SnAgCu) are exquisite solders.

Melting Point: A higher range of the melting point is around 217°C or more and requires delicate temperature control.

Workability: A bit difficult to use, especially for beginners, because of the wide range of temperatures and not as fluid.

Electrical Conductivity: Quite good, although slightly lower than lead solder.

Mechanical Strength: It may be brittle at times, leading to failure in conditions of mechanical load or thermal strands.

Health and Environmental Impact: More user friendly and eco-friendly preventing health risk of lead poisoning.

Regulation Compliance: Current standards of environment and health care practices are entirely met and, therefore, serve as the standard for use around consumer electronics or companies concerned about the environment.

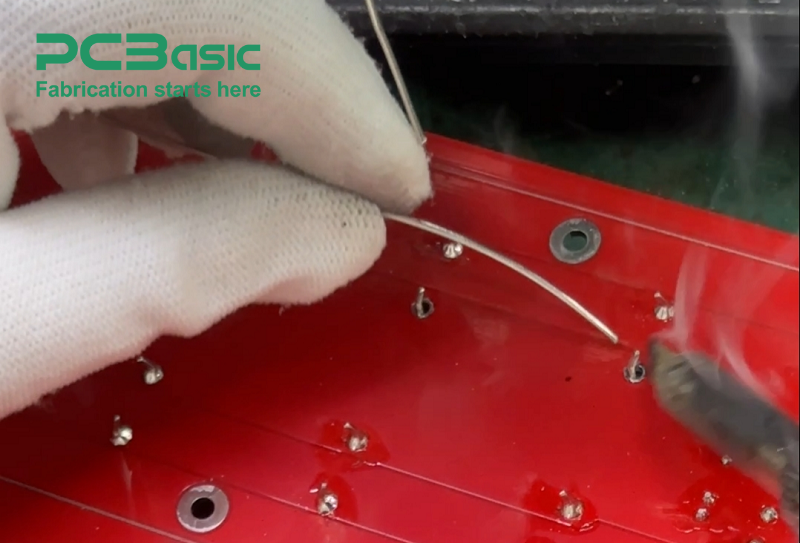

Solder Wire

The best solder for circuit board wire is the most widely used item with regard to manual soldering; it is offered in a variety of diameters for use in several applications. Many solder wires have a flux core in them, which makes the process of soldering easier since it cleans the surfaces needing solder and aids the solder in flowing correctly.

Solder Paste

Solder paste is a mixed substance that contains small solder balls within the fluxes. They are stenciled onto the best solder for circuit board for surface mount technology along with components that are placed using a reflow furnace. This furnace heats the circuit board up, which then causes the solder paste to melt and form, enabling it.

Solder Bars

Solder bars, on the other hand, are made use of wave soldering techniques and are utilized in large-scale machinery production. To solder multiple joints simultaneously on the reverse sides of circuit boards molten solder bars are employed. These are hugely effective and helpful in mass production and soldering but the tools employed in the whole process are very much specialized.

Kester 44 is widely known in the soldering community for its high activity rosin flux, which has ensured fast and strong best solder for electronics joints through the use of Kester solder wire. Making it one of the best solder for circuit boards for professionals and hobbyists alike. Noting the efficiency and consistent results produced by the Kester 44, there has been a variety of applications catering to it.

The Alpha Fry AT-31604 provides solder wire for both basic users and experienced ones. This solder wire provides smooth flow and durability with reliable soldering work. Since the wire uses rosin soldering flux, it makes the best solder for the circuit board much easier.

The best feature of MG Chemicals 63/37 solder is that it has a no-clean formula that prevents the need for any cleaning after the soldering process. It comes in a eutectic composition of 63% tin and 37% lead, which forms solid joints rapidly once the liquid solder is applied.

The WYCTIN 60/40 solder wire is known for its rosin cored solder wiresfully and stronger solder connections. This solder wire allows for smooth and reliable connections, making it one of thebest solder for circuit board among hobbyists for its simplicity. With this wire, the soldering performance is always at a good level.

SRA Soldering Products provides a good-quality rosin core solder that decreases the joining time and offers good solder links. Due to the good and stable performance of soldering and easy operability of solder, this type of solder is quite popular with both amateurs and professionals.

Cardas soldering wire is highly appreciated in the audiophile community because of its unique electrical solder characteristics. It has a combination of tin, lead, silver, and copper which makes it suitable for high quality audiowire applications. Such composition results in reduced loss of signal and excellent sound quality.

Harris Stay-Brite is a silver-bearing solder that is strong and tensile. It is best used in high reliability places such as high performance applications. The presence of silver helps in improving the properties of the best solder for circuit board joints.

Worthington 60/40 solder wire can fit the budget for what is needed, and it is reliable. It works great for general soldering, so it is a great multipurpose tool. Its lad and tin ratio helps in wire having a good flow and performance which is wanted by anyone working with it which means it is one of the best solder for circuit board option for hobbyists and professionals.

The alloy composition of solder affects its melting point el, electric conductivity, and mechanical strength. Making the right decisions for the compositions makes a difference when attaching a contact for both performance and reliability of your best solder for circuit board.

Melting point is soldering ease and stress limit of the element. Most lead-free solders usually have high melting point so they require higher temperature control when soldering.

Flux is one of the key components since it aids in getting rid of any oxidation and enhancing solder wetting to meet the requirements of getting the best solder for the circuit board. Flux can also come in different types, such as rosin, water washables, and no cleans. The choice of flux type will depend on the cleaning needs as well as the intended purpose of the application.

The solder diameter or solder wire width is important, as it determines how solder is utilized in different parts or components. Fine work can be accomplished with thinner wires, like when using fine-pitch surface mount components, while larger and thicker solder wires work perfectly with larger joints and through-hole components.

Getting proper tools can greatly improve your soldering experience and ease the entire process to get the best solder for the circuit board. For one, having a good soldering iron with adjustable thermoregulation control is a must. Having several tips is also favorable as it helps you accomplish different soldering tasks efficiently.

Minimizing contamination through a clean and organized workspace will also help raise the quality of the soldering. Never use dusty or dirty tools or components, and make sure that the area you are working is well-lit and ventilated.

Components are, in themselves, fragile and could be damaged; therefore, it is important to clean the oxidations and contaminants before soldering. For cleaning, use an isopropyl alcohol with a lint-free cloth and rub the solder joint. Use caution to avoid ripping the joints apart because they are delicate. Such rigorous techniques will only bring better sealing integrity, making the leads and Joints stronger.

Soldering is a delicate procedure, and it is important to ensure that the capacitors and components are not overheated when soldering, which may result in violating the means of control. Always check the best solder for the circuit board manufacturer's specifications. Also, two low temperatures must always be avoided as they do not guarantee cold solder joints or the like.

Oxidative smudges on the soldering tip slow it down and may result in poor tip calibration, so ensure that the tip is regularly cleaned with brass wire or tornado mushrooms while soldering. Additionally, a sponge can also be used to prevent overheating of the tip as it maintains adequate tip calibration.

Always look over the work you have done. Any regrets or changes that need to be made should be changed immediately and should not be avoided or ignored while soldering your joints. Dull Solder marks could also be contributed to poor soldering, assembly, and overheating so redo all of it. Take steps to ensure that the connections are smooth and shiny because these are the benchmarks of the best solder for circuit board flow.

To avoid insufficient heat, tighten the soldering joint because low temperatures are often a major cause of cold solder joints.

Causes: movement of joints or when an insufficient amount of time is provided for the solder to solidify.

Effect: Impedes strong electrical and mechanical connections.

Prevention: Proper working temperature is maintained for the soldering iron, and the joint is held for a few seconds until the solder hardens.

Causes: Using too much solder or bridging between adjoining pads/pins.

Prevention: The right quantity of solder should be used, and excess solder can be removed using a solder wick or a desoldering pump. Inspect your work to identify and repair bridges as soon as possible.

Causes: Tar deposits on the components, unclean components, lack of, or too little solder flux, and incorrect soldering temperatures.

Prevention: Start cleaning all the surfaces that are to be soldered properly, using the right type of solder flux, and making sure that the tip of the soldering iron is hot enough for good wetting and strong bonds.

To manufacture the best solder for circuit boards, the proper solder and the soldering practice have to be performed correctly. Knowing the various types, the composition, and the methods of soldering will allow you to sharpen your soldering skills and get better results in your projects. Think of this guide as a reference to picking the best solder for the circuit board you want, enabling you to tackle popular soldering problems and build high-quality electronic devices without much hassle. Happy soldering!

Assembly Enquiry

Instant Quote